Flue gas treatment device

A technology for flue gas treatment and flue gas, which is applied in gas treatment, membrane technology, and separation of dispersed particles. The effect of reducing the amount and dust content and reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

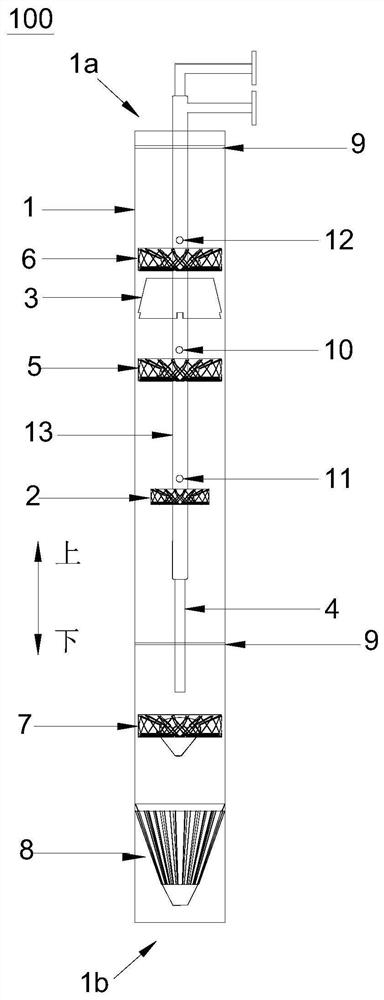

[0024] figure 1 It is a schematic structural diagram of a flue gas treatment device according to an embodiment of the present invention. Such as figure 1 As shown, the flue gas treatment device 100 is a flue gas denitrification tower, a flue gas desulfurization tower or a flue gas desulfurization and denitrification tower, and the purification liquid includes a desulfurizer (Na2CO3, NaOH or Ca(OH)2, etc.) and / or a denitrification agent. The flue gas treatment device 100 is suitable for use in flue gas discharge places of small and medium-sized boilers, steelmaking, aluminum smelting, ships, etc., and other chemical and non-electric factories.

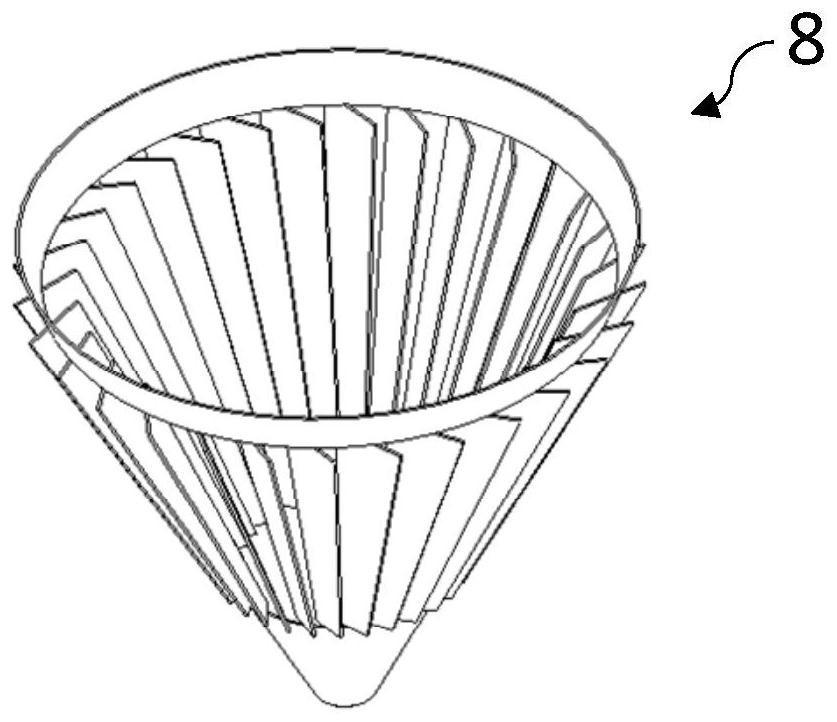

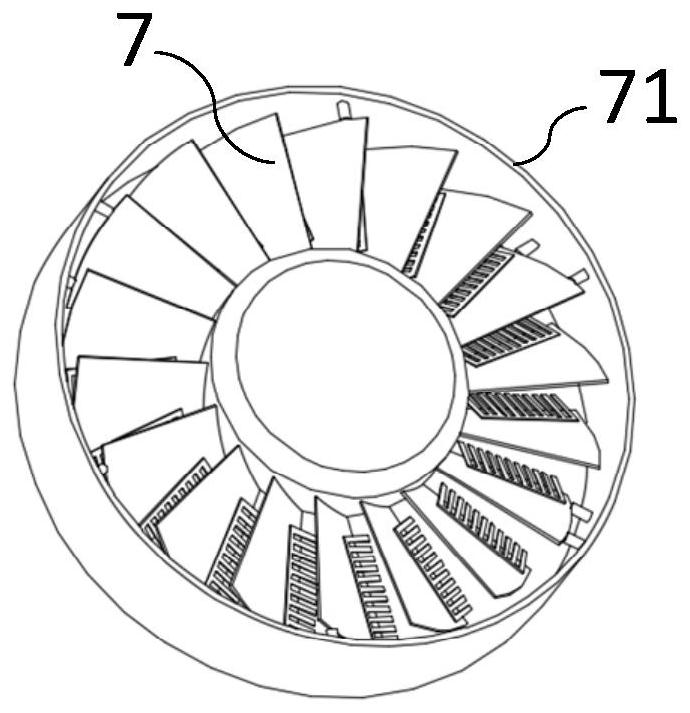

[0025] The flue gas treatment device 100 includes a cylinder body 1, a guide core pipe 4, a purification impeller 7, and a mist removal assembly (such as a first mist removal impeller 6, a second mist removal impeller 5 and / or a th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap