Cerium iron zirconium solid solution oxide catalyst and its preparation and application

A technology of oxides and solid solutions, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve the problem of narrow air-fuel ratio window, high light-off temperature, Enhance oxygen storage capacity and other issues to achieve the effects of avoiding crystal phase precipitation, increasing lattice distortion, and high oxygen storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

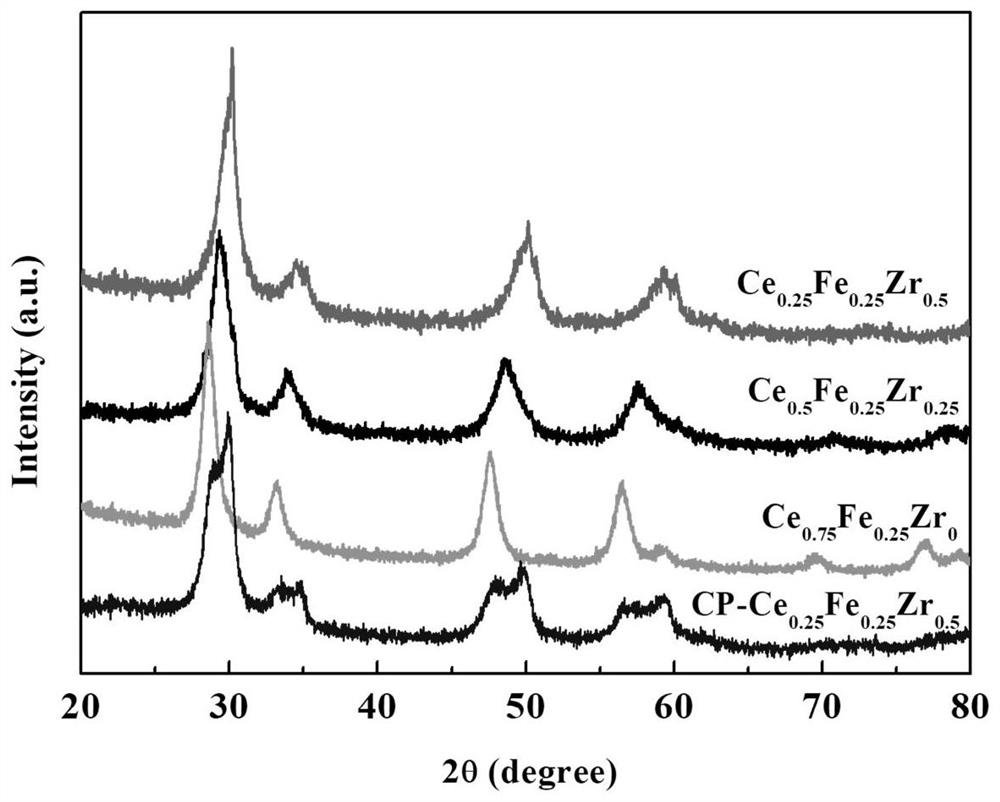

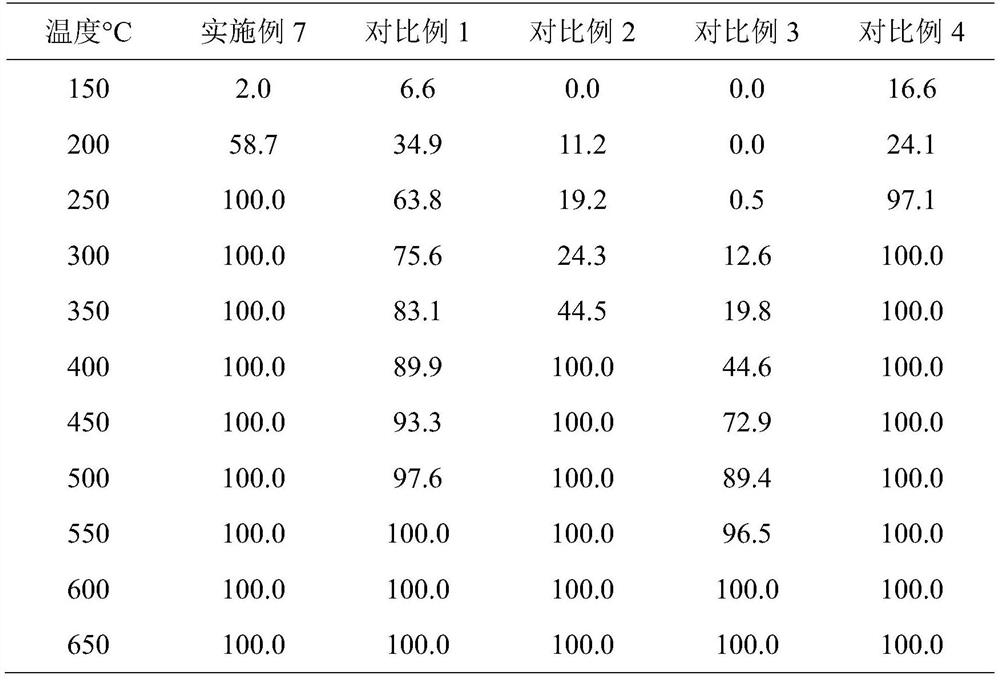

Embodiment 1

[0015] 21.8g of cerium 2-ethylhexanoate and 2-ethylhexanoic acid mixture (Ce content 12%), 2.252g of iron acetylacetonate and 28ml xylene are mixed to prepare a precursor solution, and the concentration of the precursor is 0.5mol / L. Use a syringe to pump the prepared solution into the flame at a rate of 5ml / min. The flame combustion gas is a mixture of methane (0.6L / min) and oxygen (1.9L / min), and the formed oxide particles are driven by the high-speed air (5L / min) to leave the flame area quickly. The catalyst is denoted as Ce 0.75 Fe 0.25 .

Embodiment 2

[0017] Mix 14.88g of cerium 2-ethylhexanoate and 2-ethylhexanoic acid mixture (Ce content 12%), 2.252g of iron acetylacetonate, 3.112g of zirconium acetylacetonate and 36ml xylene to prepare a precursor solution , the precursor concentration is 0.5mol / L. Use a syringe to pump the prepared solution into the flame at a rate of 5ml / min. The flame combustion gas is a mixture of methane (0.6L / min) and oxygen (1.9L / min), and the oxide particles formed quickly leave the flame area driven by the high-speed air (5L / min) flow, and the prepared The catalyst is denoted as Ce 0.5 Fe 0.25 Zr 0.25 .

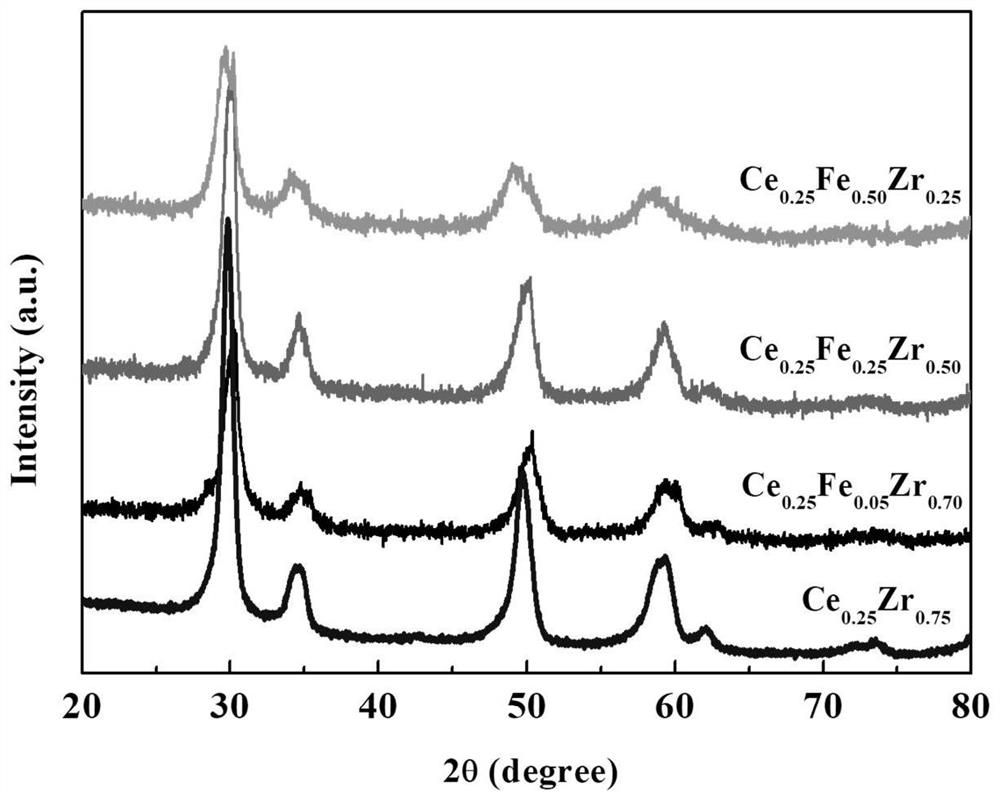

Embodiment 3

[0019] Mix 13.12g of cerium 2-ethylhexanoate and 2-ethylhexanoic acid mixture (Ce content 12%), 3.97g of iron acetylacetonate, 10.97g of zirconium acetylacetonate and 77ml xylene to prepare a precursor solution , the precursor concentration is 0.5mol / L. Use a syringe to pump the prepared solution into the flame at a rate of 5ml / min. The flame combustion gas is a mixture of methane (0.6L / min) and oxygen (1.9L / min), and the oxide particles formed quickly leave the flame area driven by the high-speed air (5L / min) flow, and the prepared The catalyst is denoted as Ce 0.25 Fe 0.25 Zr 0.5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com