Vertically partitioned anoxic and aerobic precipitation integrated sewage treatment system and stirring and aeration integrated device thereof

A stirring aeration and agitator technology, applied in the field of water treatment, can solve the problems of unstable effluent water quality, increased energy consumption, low sludge concentration, etc., to improve sewage treatment efficiency, facilitate installation and disassembly, and simplify the assembly process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

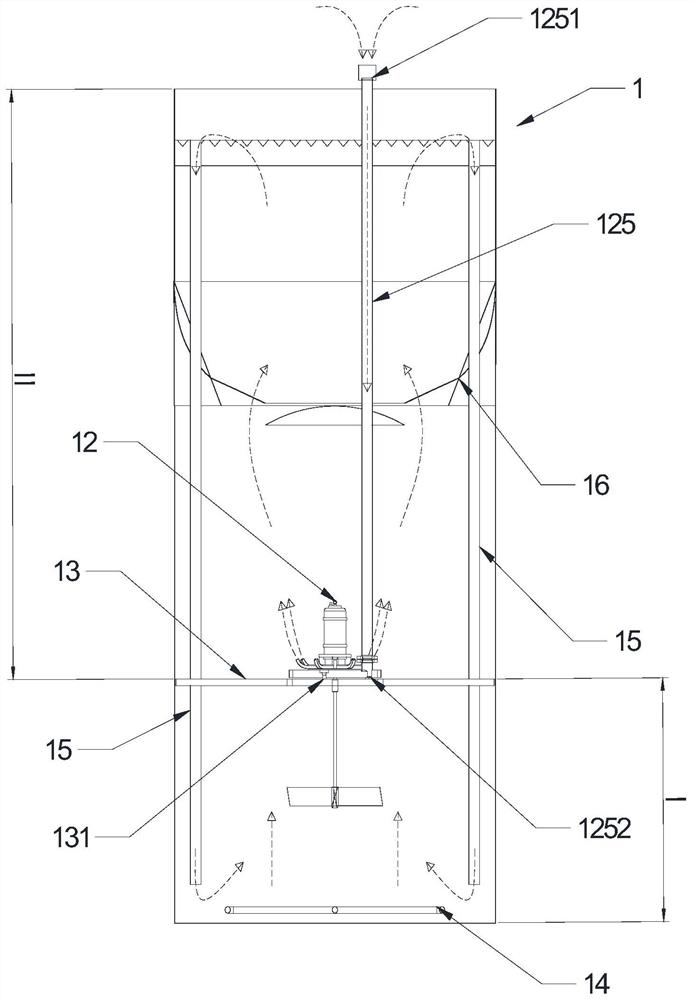

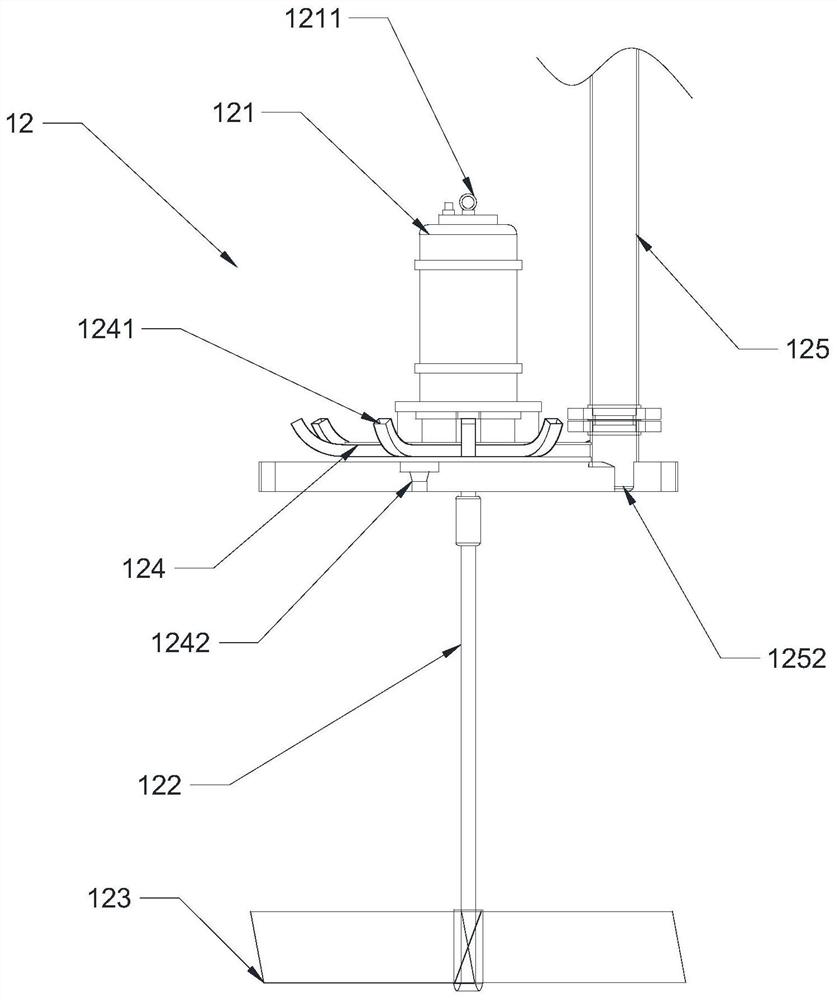

Embodiment 1

[0041] The average raw water quality of domestic sewage in a township is: COD (Chemical Oxygen Demand, chemical oxygen demand) 225mg / L (mg per liter), ammonia nitrogen 30mg / L, total nitrogen 40mg / L, total phosphorus 2.0mg / L, collected After the pool is collected, adopt the anoxic aerobic precipitation integrated sewage treatment system 1 of the vertical partition of the application, the sewage enters the anoxic reaction zone through the raw water distribution pipe, and the agitator in the anoxic zone located in the anoxic reaction zone provides stirring power, and the water level Gradually ascend into the aerobic reaction zone. The submersible aerator in the aerobic reaction zone sucks in air through the negative pressure suction pipe protruding from the water surface, and then releases the dissolved air water through the release tube at the bottom. On the one hand, it provides the oxygen needed for the aerobic reaction. Oxygen, on the other hand, provides the power of air-lift...

Embodiment 2

[0043] The domestic sewage in a highway service area, the raw water quality is: COD 280mg / L, ammonia nitrogen 60mg / L, total nitrogen 80mg / L, total phosphorus 4.0mg / L, using the vertical partition anoxic aerobic precipitation integrated sewage of this application Treatment system 1, the sewage enters the anoxic reaction zone through the raw water distribution pipe, the agitator in the anoxic zone located in the anoxic reaction zone provides stirring power, the water level gradually rises into the aerobic reaction zone, and the submersible aerator in the aerobic reaction zone The negative pressure suction pipe on the water surface sucks in air, and then releases the dissolved air water through the release pipe at the bottom. On the one hand, it provides the oxygen required for the aerobic reaction, and on the other hand, it provides the power of air-lift circulation. The nitrifying liquid in the upper part of the aerobic reaction zone After being collected through the nitrificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com