Method for constructing On-DNA alpha-amino amide compound through aqueous-phase Ugi multi-component reaction

A multi-component reaction and aminoamide technology, applied in the field of coding compound libraries, can solve problems such as low efficiency and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

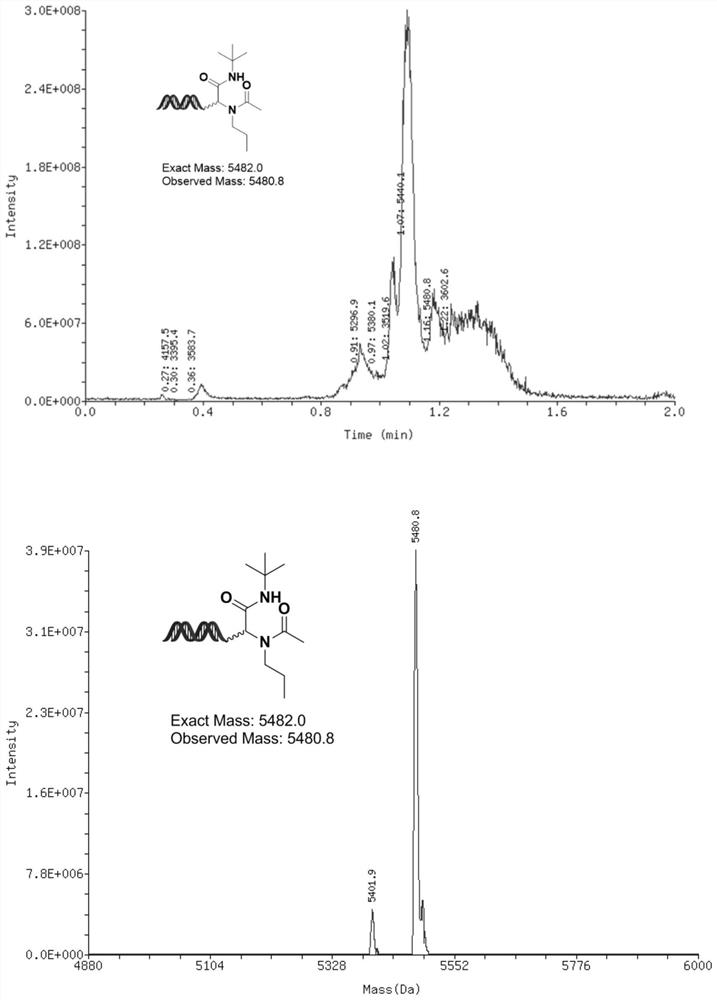

[0142] The synthesis of embodiment 1, compound 1

[0143]

[0144] Propylamine (6.67μL, 333 molar equivalents, 1M MeOH solution) and DNA-CHO (20μL, 20nmol, 1mM aqueous solution) were pre-mixed evenly, and the reaction solution was activated at room temperature for 2 hours. After activation, add Acetic acid (6.67 μL, 333 molar equivalents, 1M MeOH solution), then add tert-butylisonitrile (6.67 μL, 333 molar equivalents, 1M MeOH solution), mix the reaction solution thoroughly, and then place the reaction solution at 60°C The next 16 hours.

[0145] After the reaction is completed: ethanol precipitation, add 4 μL, 5M sodium chloride solution to the solution, and then continue to add 120 μL absolute ethanol, after shaking evenly, freeze the reaction at -20°C for 2 hours, and then centrifuge at high speed After half an hour, the supernatant was discarded, and the remaining precipitate was dissolved in deionized water to obtain compound 1 with a conversion rate of 15%.

Embodiment 2

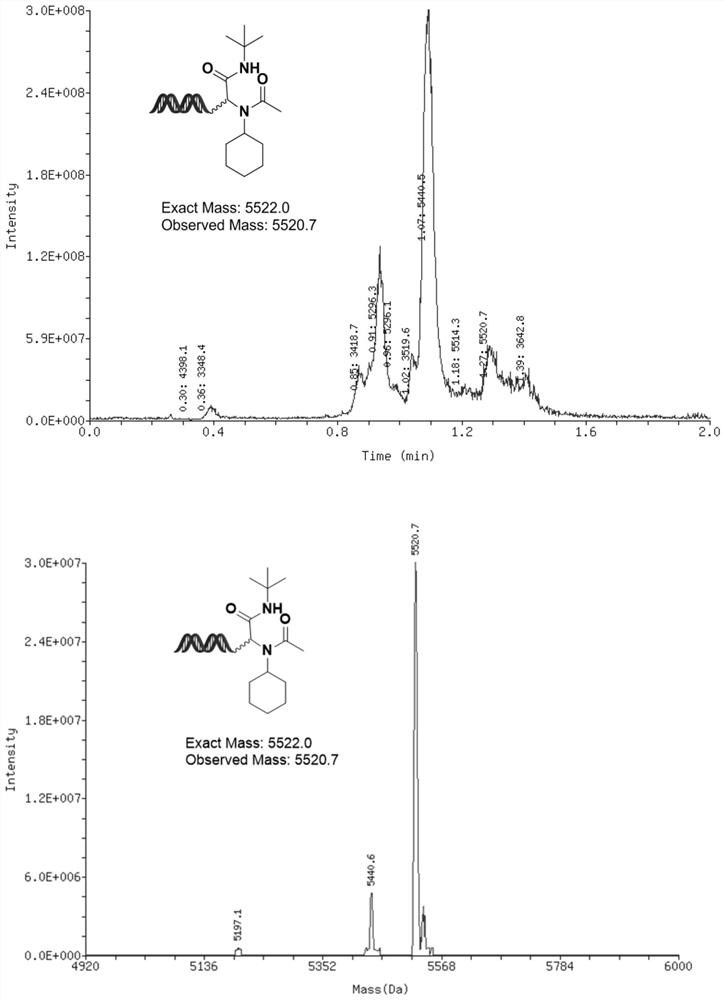

[0146] The synthesis of embodiment 2, compound 2

[0147]

[0148] Cyclohexylamine (6.67 μL, 333 molar equivalents, 1M MeOH solution) and DNA-CHO (20 μL, 20 nmol, 1 mM aqueous solution) were pre-mixed uniformly, and the reaction solution was activated at room temperature for 2 hours. After activation, First add acetic acid (6.67 μL, 333 molar equivalents, 1M MeOH solution), then add tert-butylisonitrile (6.67 μL, 333 molar equivalents, 1M MeOH solution), mix the reaction solution thoroughly, and then place the reaction solution at 60 16 hours under the condition of ℃.

[0149] After the reaction is completed: ethanol precipitation, add 4 μL, 5M sodium chloride solution to the solution, and then continue to add 120 μL absolute ethanol, after shaking evenly, freeze the reaction at -20°C for 2 hours, and then centrifuge at high speed After half an hour, the supernatant was discarded, and the remaining precipitate was dissolved in deionized water to obtain compound 2 with a co...

Embodiment 3

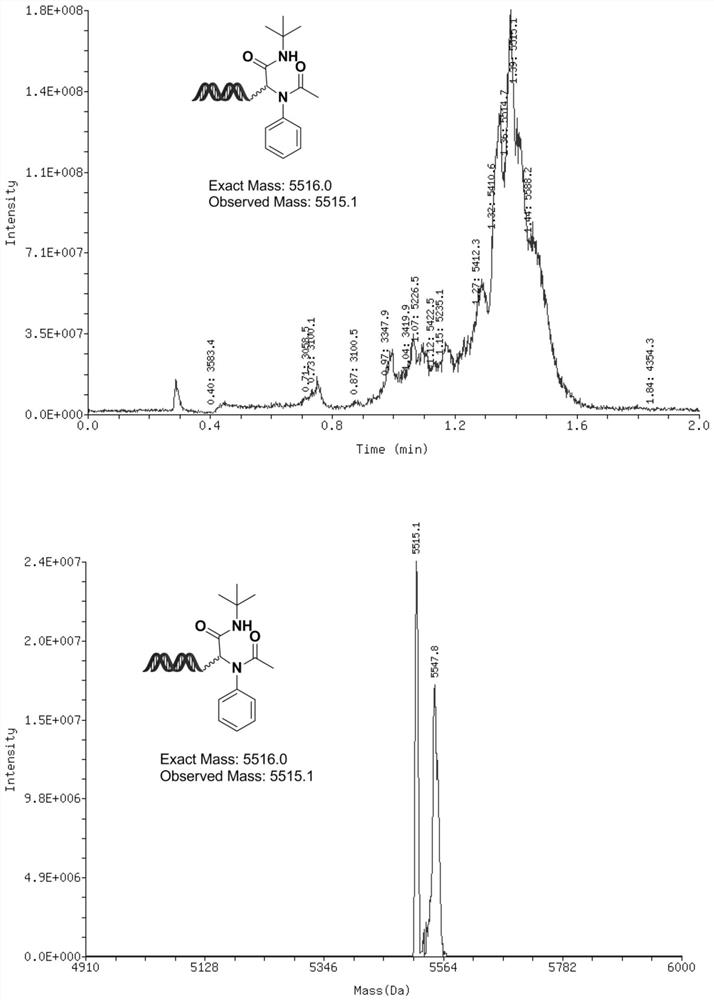

[0150] The synthesis of embodiment 3, compound 3

[0151]

[0152] Mix aniline (6.67μL, 333 molar equivalents, 1M MeOH solution) and DNA-CHO (20μL, 20nmol, 1mM aqueous solution) in advance, and activate the reaction solution at room temperature for 2 hours. After activation, add Acetic acid (6.67 μL, 333 molar equivalents, 1M MeOH solution), then add tert-butylisonitrile (6.67 μL, 333 molar equivalents, 1M MeOH solution), mix the reaction solution thoroughly, and then place the reaction solution at 60°C The next 16 hours.

[0153] After the reaction is completed: ethanol precipitation, add 4 μL, 5M sodium chloride solution to the solution, and then continue to add 120 μL absolute ethanol, after shaking evenly, freeze the reaction at -20°C for 2 hours, and then centrifuge at high speed After half an hour, the supernatant was discarded, and the remaining precipitate was dissolved in deionized water to obtain compound 3 with a conversion rate of 51%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com