Modified phenolic resin and preparation method thereof

A phenolic resin and modification technology, applied in the field of modified phenolic resin and its preparation, can solve the problems of product defects, reduced toughness of modified PF, and high curing temperature, and achieve regular molecular structure, strong heat resistance, and curing temperature. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

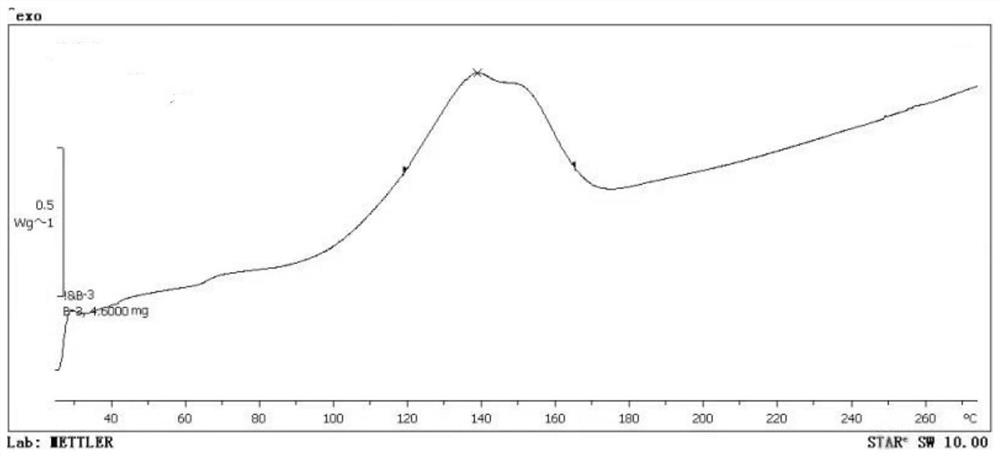

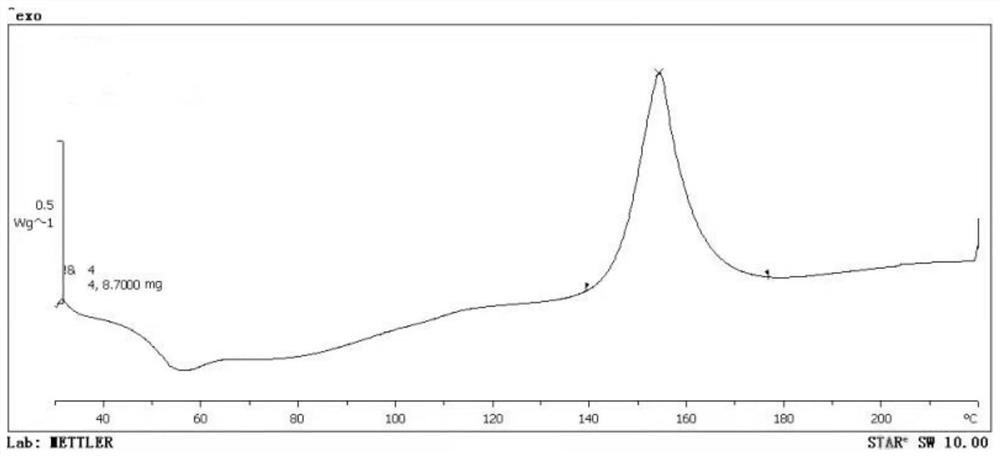

Image

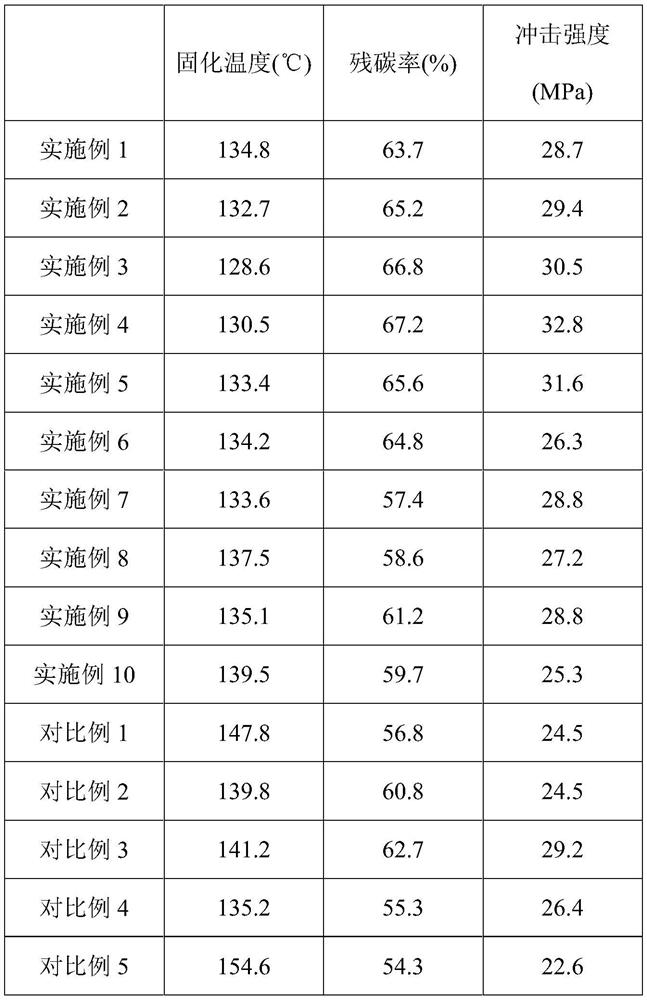

Examples

Embodiment 1

[0028] (S1) In a closed reactor, add 100 parts of phenol and 15 parts of 4-maleimidophenol to the reactor in turn, add 4 parts of ammonia water (15wt% concentration), and heat up to 85°C; the temperature rises to 80°C Add a mixture of 90 parts of formaldehyde and 18 parts of resorcinol dropwise at ℃, the time for the dropwise addition is 2 hours, and keep warm for 2 hours after the addition is completed;

[0029] (S2) Continue to heat up to 95°C, add 0.2 parts of barium hydroxide, start to drop a mixture of 30 parts of furfural and 8 parts of resorcinol, dropwise for 1 hour, keep warm for 2 hours, add phosphoric acid to adjust the reaction system The pH value of the modified phenolic resin is 7-8, and the modified phenolic resin can be obtained by vacuum dehydration at 70°C.

Embodiment 2

[0031] Other conditions are consistent with Example 1, the difference is that 4-maleimidophenol is 20 parts.

Embodiment 3

[0033] Other conditions are consistent with Example 1, the difference is that 4-maleimidophenol is 25 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com