UV-LED fluorescent ink and preparation method thereof

A UV-LED, fluorescent ink technology, applied in inks, household appliances, applications, etc., can solve the problems of poor stability of fluorescent ink, can not satisfy consumers, and the color is not beautiful enough to improve printing stability, good fluorescent effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of UV-LED fluorescent ink, comprising the following steps:

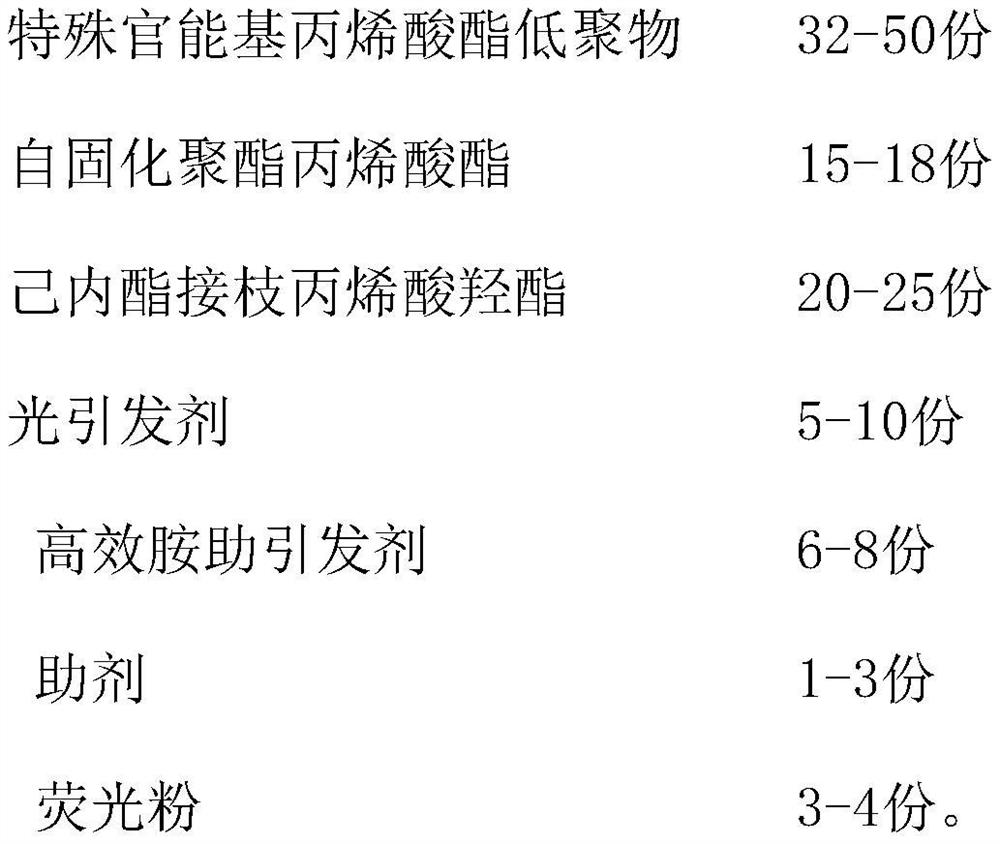

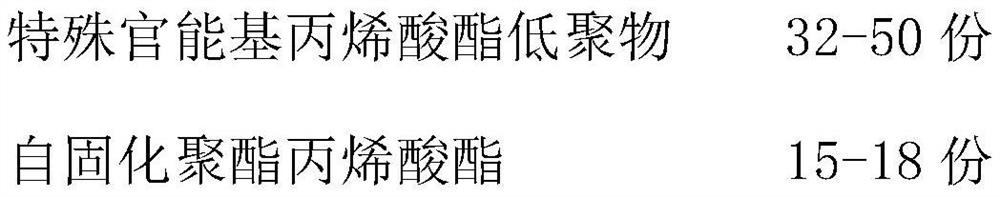

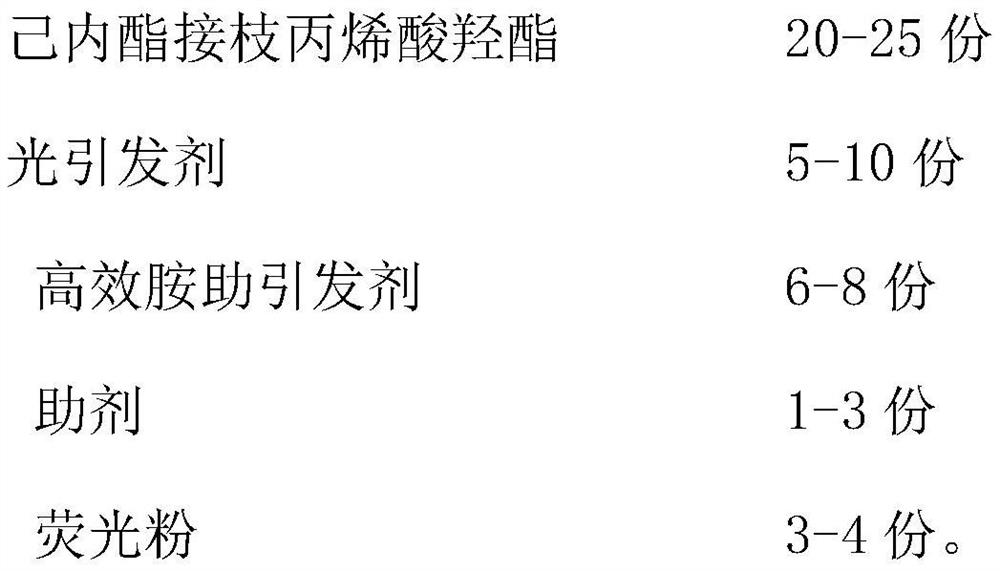

[0029] S1, weigh the components according to the weight ratio in Table 1;

[0030] S2. Put the caprolactone-grafted hydroxyacrylate, high-efficiency amine co-initiator and photoinitiator into the container, stir and mix evenly, the stirring time is 15 minutes, the stirring speed is 3000 rpm, and the stirring condition is 60°C , the pressure is normal pressure;

[0031] S3. Slowly add fluorescent powder and additives, stir and mix evenly, the stirring time is 60 minutes, the stirring speed is 1000 rpm, and the stirring conditions are normal temperature and normal pressure;

[0032] S4. Slowly add self-curing polyester acrylate and special functional acrylate oligomer, stir and mix evenly, the stirring speed is 1800 rpm, the stirring time is 30 minutes, and the stirring conditions are normal temperature and normal pressure.

Embodiment 2

[0034] A preparation method of UV-LED fluorescent ink, comprising the following steps:

[0035] S1, weigh the components according to the weight ratio in Table 1;

[0036] S2. Put the caprolactone-grafted hydroxyacrylate, high-efficiency amine co-initiator and photoinitiator into the container, stir and mix evenly, the stirring time is 10 minutes, the stirring speed is 2500 rpm, and the stirring condition is 55°C , the pressure is normal pressure;

[0037] S3. Slowly add fluorescent powder and additives, stir and mix evenly, the stirring time is 50 minutes, the stirring speed is 1000 rpm, and the stirring conditions are normal temperature and normal pressure;

[0038] S4. Slowly add self-curing polyester acrylate and special functional acrylate oligomer, stir and mix evenly, the stirring speed is 1500 rpm, the stirring time is 30 minutes, and the stirring conditions are normal temperature and normal pressure.

Embodiment 3

[0040] A preparation method of UV-LED fluorescent ink, comprising the following steps:

[0041] S1, weigh the components according to the weight ratio in Table 1;

[0042] S2. Put the caprolactone-grafted hydroxyacrylate, high-efficiency amine co-initiator and photoinitiator into the container, stir and mix evenly, the stirring time is 20 minutes, the stirring speed is 3000 rpm, and the stirring condition is 60°C , the pressure is normal pressure;

[0043] S3. Slowly add fluorescent powder and additives, stir and mix evenly, the stirring time is 60 minutes, the stirring speed is 800 rpm, and the stirring conditions are normal temperature and normal pressure;

[0044] S4. Slowly add self-curing polyester acrylate and special functional acrylate oligomer, stir and mix evenly, the stirring speed is 2000 rpm, the stirring time is 30 minutes, and the stirring conditions are normal temperature and normal pressure.

[0045] Table 1: The weight ratio of the UV-LED fluorescent ink of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap