Super-hydrophobic anti-icing and deicing coating with photothermal effect and preparation method thereof

A photothermal effect and super-hydrophobic technology, applied in the direction of coating, etc., can solve the problems of insufficient anti-icing ability, achieve excellent super-hydrophobic performance, simple preparation process, and realize the effect of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A kind of superhydrophobic anti-icing deicing coating with photothermal effect and preparation method thereof, comprises the following steps:

[0051] S1. First weigh 0.05g of melanin nanoparticles and disperse them in 20g of ethyl acetate solution, then add 0.2g of PDMS prepolymer component A and 0.02g of curing agent component B in sequence, and stir for 2 hours at room temperature.

[0052] S2. Then, spray the solution in step 1 on the glass sheet with a distance of 10 cm between the nozzle and the substrate, and cure at a high temperature of 60° C. for 2 hours.

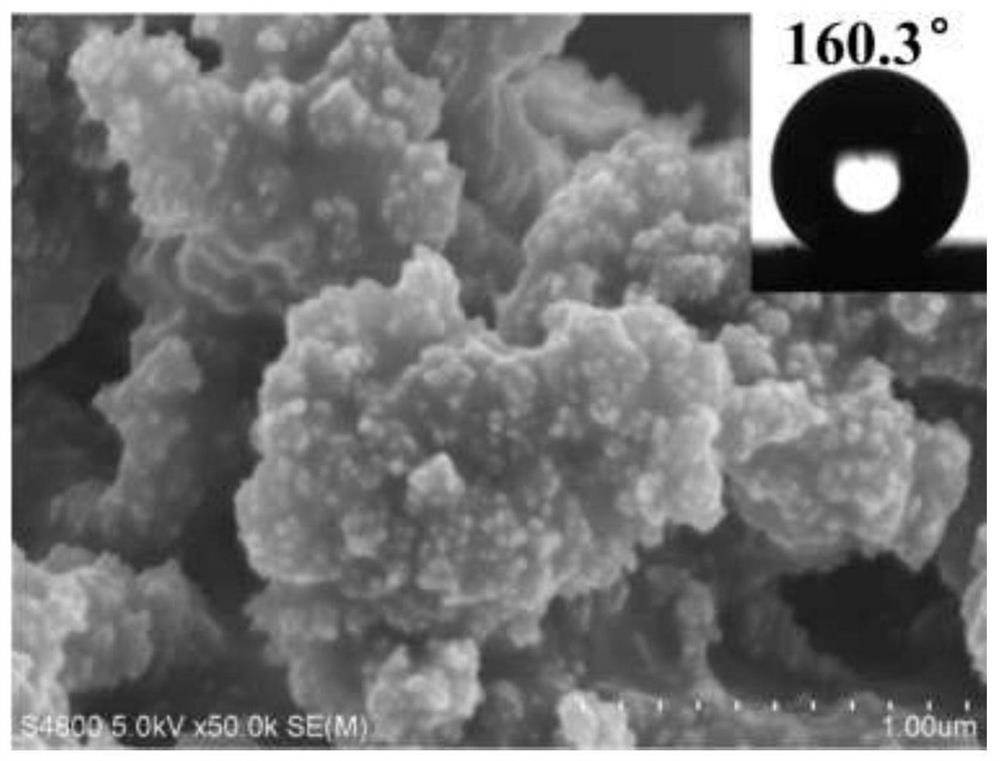

[0053] S3. Weigh 0.1 g of hydrophobized modified silicon dioxide and disperse it in 10 g of ethyl acetate solution, then spray it on a glass sheet with a distance of 10 cm between the nozzle and the substrate, and dry at 60° C. for 2 hours.

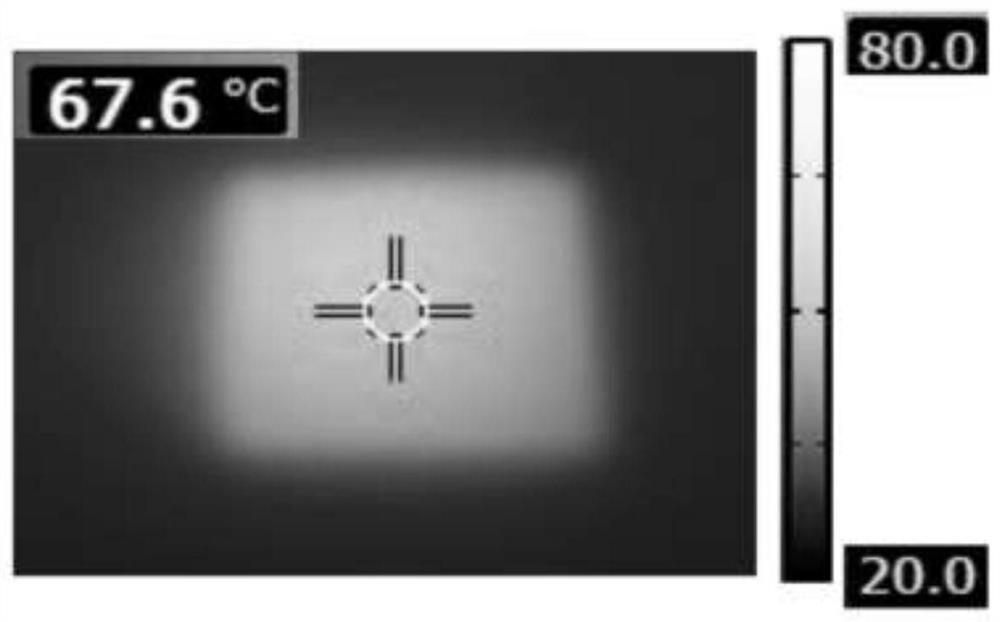

[0054] The surface temperature of the superhydrophobic anti-icing coating with photothermal deicing performance can reach 61.2°C under a strong sunlight, the contact a...

Embodiment 2

[0056] A kind of superhydrophobic anti-icing deicing coating with photothermal effect and preparation method thereof, comprises the following steps:

[0057] S1. First weigh 0.1g of melanin nanoparticles and disperse them in 20g of ethyl acetate solution, then add 0.2g of PDMS prepolymer component A and 0.02g of curing agent component B in sequence, and stir at room temperature for 2.25h.

[0058] S2. Then, spray the solution in step 1 on the glass sheet with a distance of 13 cm between the nozzle and the substrate, and cure at a high temperature of 65° C. for 2.25 hours.

[0059] S3. Weigh 0.1 g of hydrophobized modified silicon dioxide and disperse it in 10 g of ethyl acetate solution, then spray it on a glass sheet with a distance of 13 cm between the nozzle and the substrate, and dry at 65° C. for 2.25 h.

[0060] The surface temperature of the superhydrophobic anti-icing coating with photothermal deicing performance can reach 63.8°C under a strong sunlight, and the contac...

Embodiment 3

[0062] A kind of superhydrophobic anti-icing deicing coating with photothermal effect and preparation method thereof, comprises the following steps:

[0063] S1. First weigh 0.2g of melanin nanoparticles and disperse them in 20g of ethyl acetate solution, then add 0.2g of PDMS prepolymer component A and 0.02g of curing agent component B in sequence, and stir at room temperature for 2.5h.

[0064] S2. Then spray the solution in step 1 on the glass sheet with a distance of 15 cm between the nozzle and the substrate, and cure at a high temperature of 70° C. for 2.5 hours.

[0065] S3. Weigh 0.1 g of hydrophobized modified silicon dioxide and disperse it in 10 g of ethyl acetate solution, then spray it on a glass sheet with a distance of 15 cm between the nozzle and the substrate, and dry at 70° C. for 2.5 h.

[0066] The superhydrophobic anti-icing coating with photothermal deicing performance is a superhydrophobic antiicing coating with photothermal deicing performance according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface temperature | aaaaa | aaaaa |

| Water droplet contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com