Distributed optical fiber sensing device capable of monitoring steel beam crack and monitoring method

A distributed optical fiber and sensing device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as inability to accurately predict cracks, peak instability, waveguide structure failure, etc., to improve reliability and scalability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below through specific implementation manners in conjunction with the accompanying drawings.

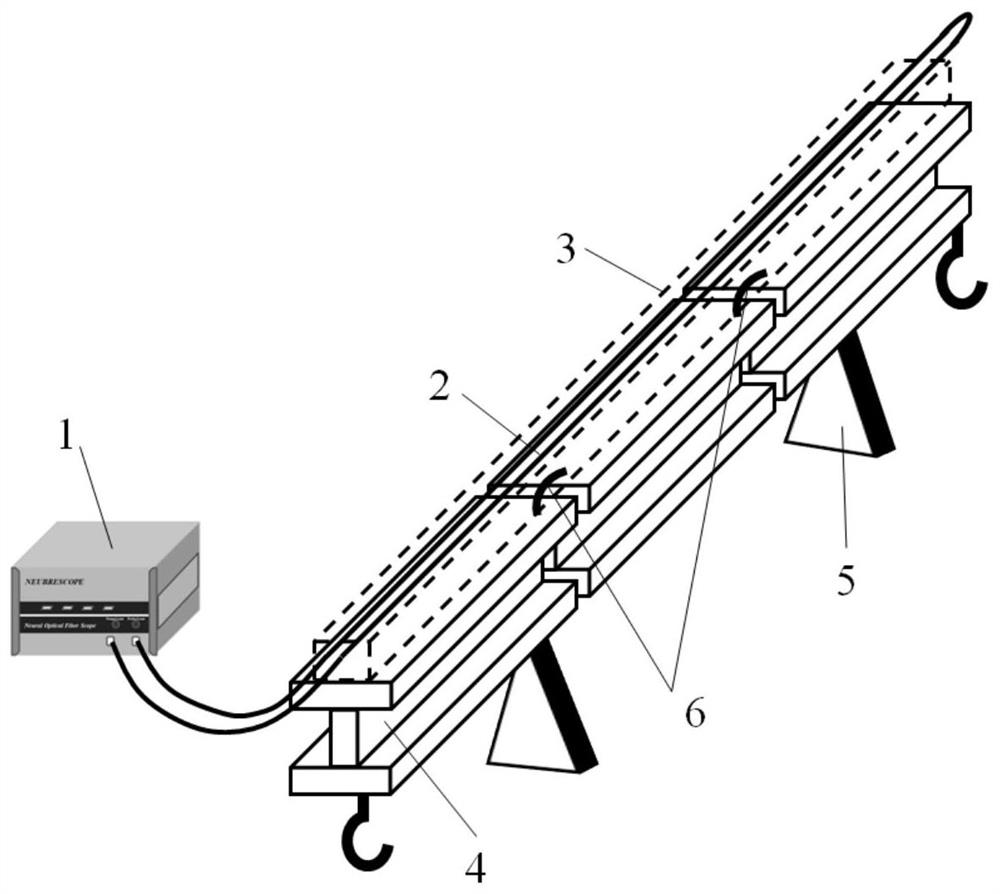

[0028] Such as figure 1 As shown, a distributed optical fiber sensing device capable of monitoring cracks in steel beams includes a sensing fiber 2 to be tested, the sensing fiber 2 to be tested is a photonic crystal fiber, and the outside of the photonic crystal fiber is covered with an epoxy resin adhesive 3 wrapped, pasted on the upper surface of the steel beam 4 along the length direction of the steel beam 4, the photonic crystal fiber is electrically connected to the BOTDA strain analyzer 1, the bottom of the steel beam 4 is provided with a bracket 5, and the bracket 5 supports the steel beam 4 from the bottom; the steel beam 4 Both ends are provided with hooks for hanging iron drums, and sand of different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com