Yarn guide wheel for diamond wire cutting machine

A diamond wire and guide wheel technology, applied in metal processing equipment, grinding machines, transportation and packaging, etc., can solve the problems of reducing the cutting surface quality and cutting efficiency of workpieces, affecting the cutting life of diamond yarn, and insufficient confining force of diamond yarn. , to achieve the effect of providing cutting quality, good non-stickiness and strong restriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

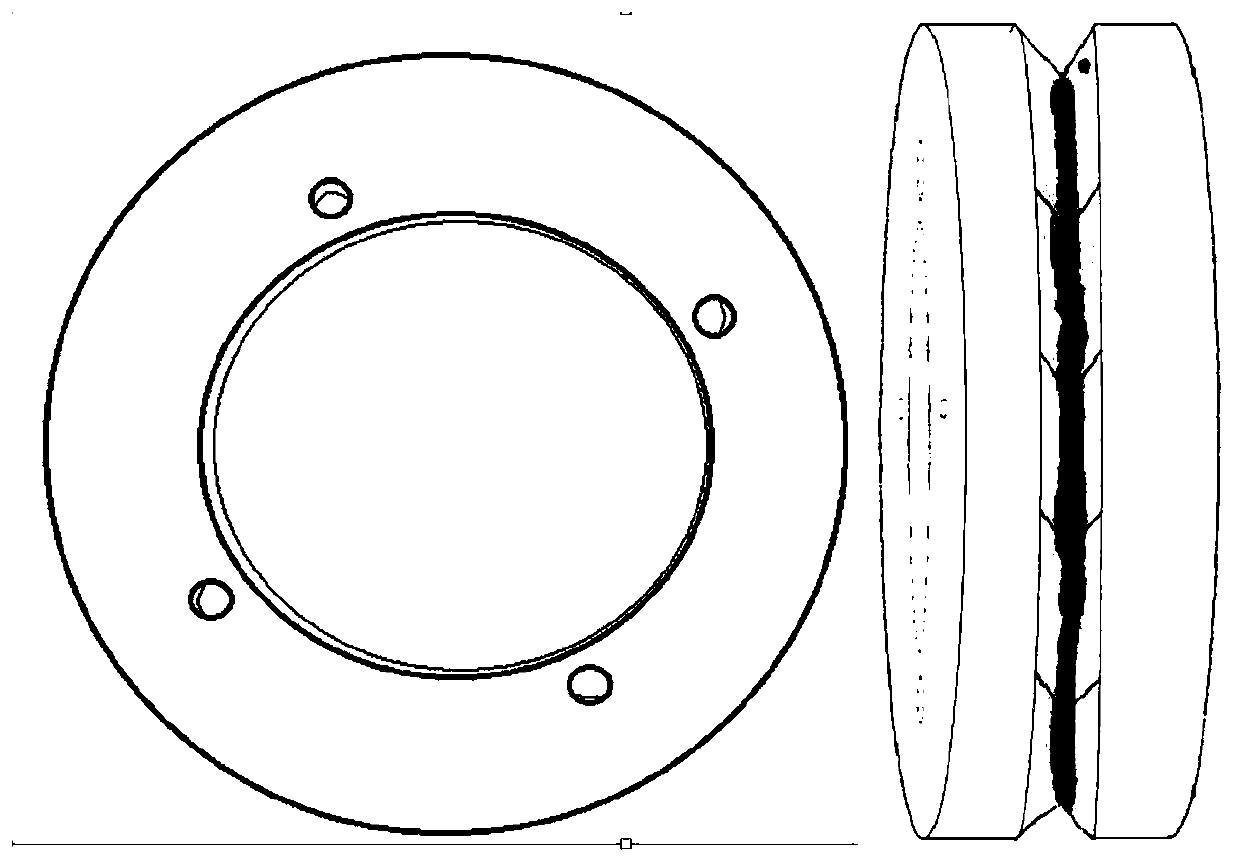

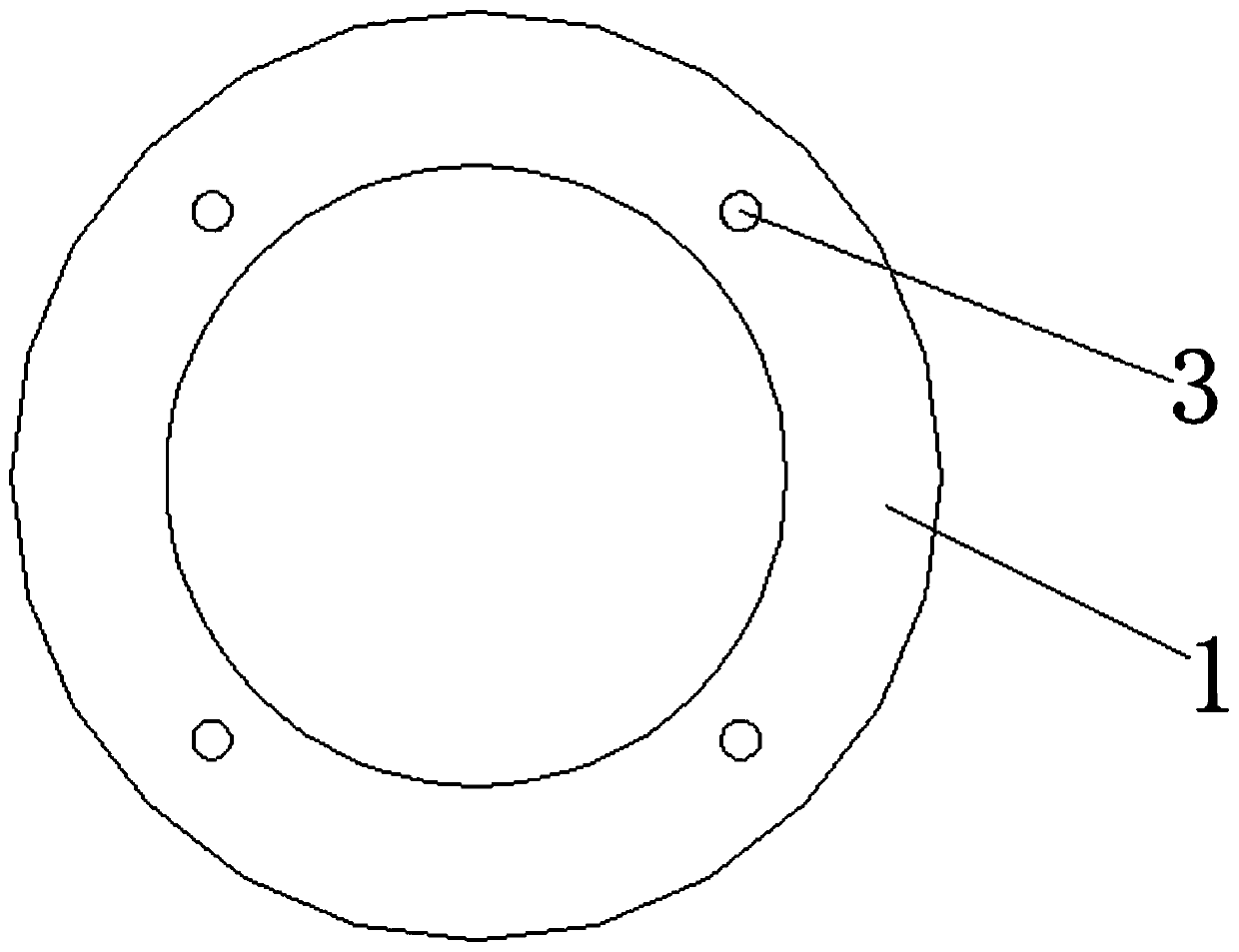

[0034] A yarn guide wheel for a diamond wire cutting lathe, which selects a low-volume wear rate, low-density ultra-high molecular polyethylene non-metallic composite material as the material for the guide wheel, and its preparation method comprises the following steps:

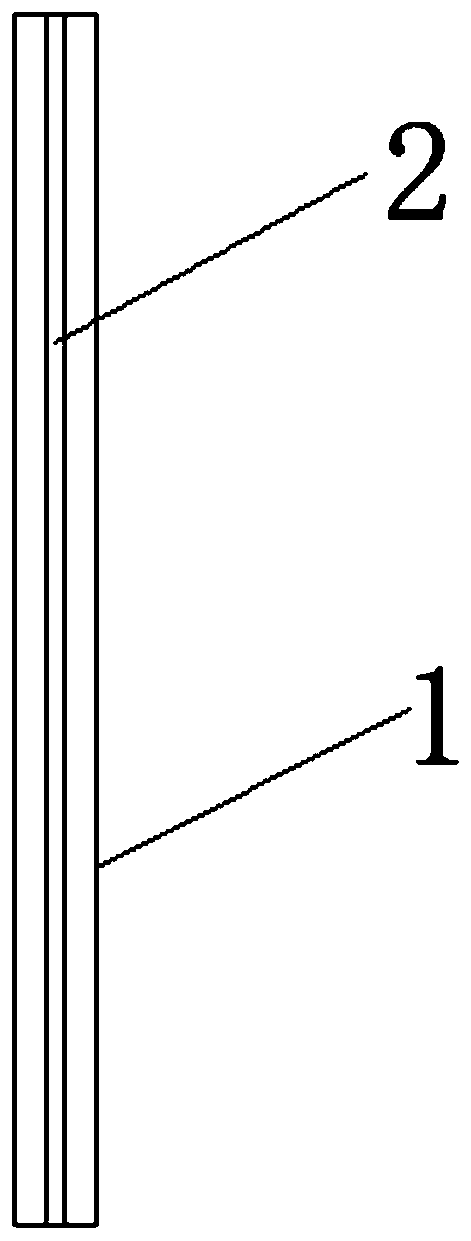

[0035] S1. Use a lathe to process the ultra-high molecular weight polyethylene non-metallic composite material with a molecular weight of 2.8 million into a ring shape with an inner diameter of 20mm, an outer diameter of 60mm, and a thickness of 8mm;

[0036] S2, use a lathe to process an in-line groove with a width of 1.1 times the diameter of the diamond yarn on the ring obtained in step S1, and process 4 fixed screw holes in a square distribution to obtain the non-metallic in-line groove Yarn guide wheel.

Embodiment 2

[0038] A yarn guide wheel for a diamond wire cutting lathe, which selects a low-volume wear rate, low-density ultra-high molecular polyethylene non-metallic composite material as the material for the guide wheel, and its preparation method comprises the following steps:

[0039] S1. Use a lathe to process the ultra-high molecular weight polyethylene non-metallic composite material with a molecular weight of 3.8 million into a ring shape with an inner diameter of 20mm, an outer diameter of 60mm, and a thickness of 8mm;

[0040] S2, use a lathe to process an in-line groove with a width of 1.2 times the diameter of the diamond yarn on the ring obtained in step S1, and process 4 fixed screw holes in a square distribution to obtain the non-metallic in-line groove Yarn guide wheel.

Embodiment 3

[0042] A yarn guide wheel for a diamond wire cutting lathe, which selects a low-volume wear rate, low-density ultra-high molecular polyethylene non-metallic composite material as the material for the guide wheel, and its preparation method comprises the following steps:

[0043] S1. Use a lathe to process the ultra-high molecular weight polyethylene non-metallic composite material with a molecular weight of 3 million into a ring shape with an inner diameter of 20mm, an outer diameter of 60mm, and a thickness of 8mm;

[0044] S2, use a lathe to process an in-line groove with a width of 1.125 times the diameter of the diamond yarn on the ring obtained in step S1, and process 4 fixed screw holes in a square distribution to obtain the non-metallic in-line groove Yarn guide wheel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com