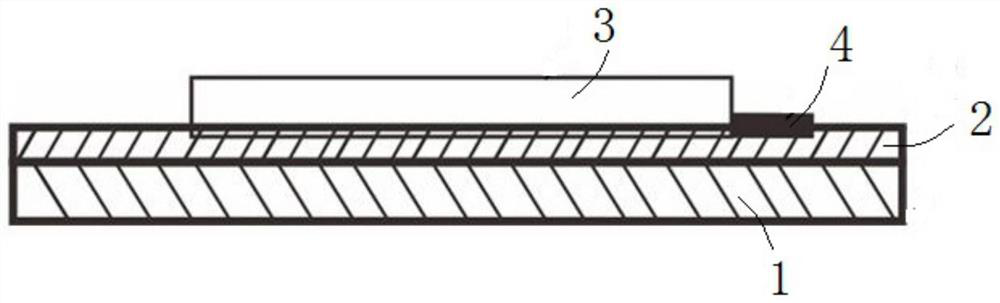

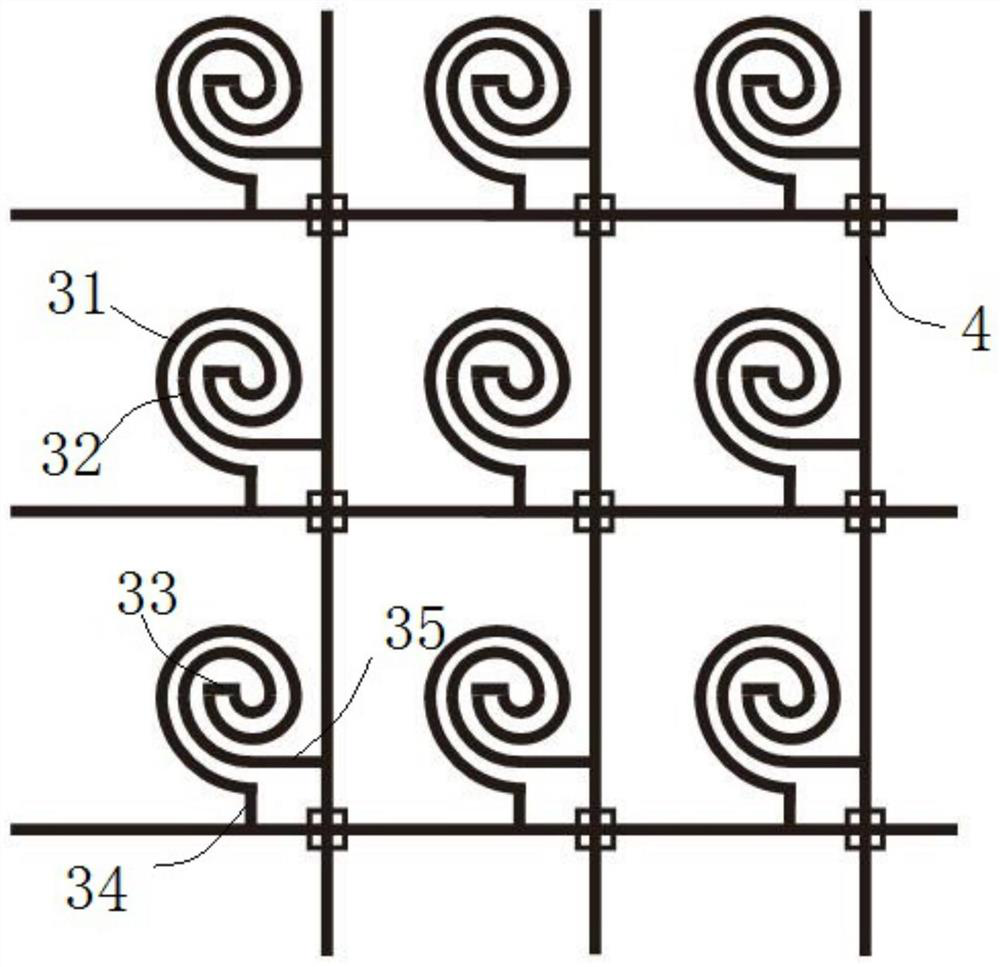

Flexible tactile sensor unit based on annular spiral fiber and preparation method

A tactile sensor and fiber unit technology, applied in the field of sensors, can solve the problems that the structure is difficult to take into account the bending characteristics and stretching characteristics, restrict the application of resistive tactile sensors, etc., and achieve the effect of excellent compatibility and strong portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

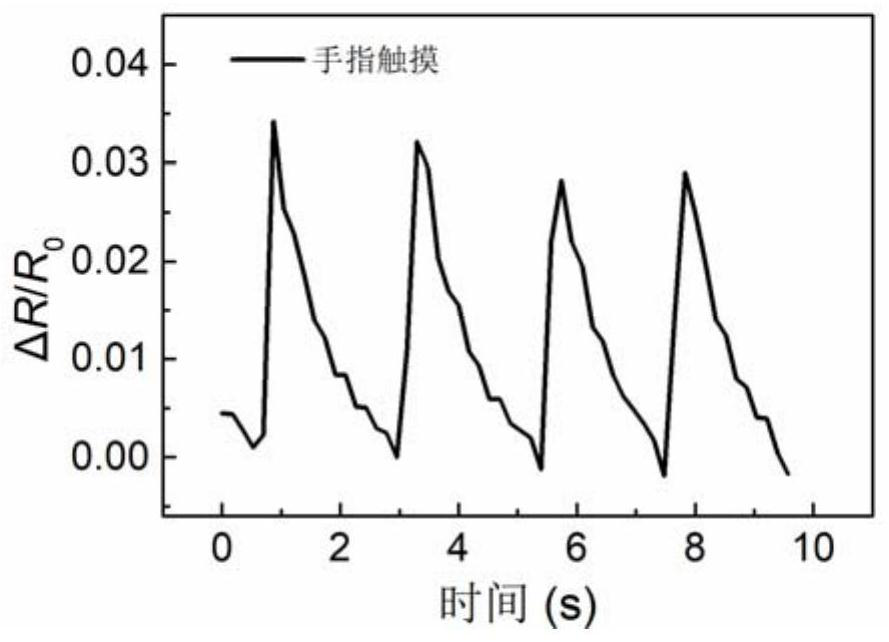

Examples

preparation example Construction

[0038] A kind of above-mentioned preparation method of the flexible tactile sensor unit based on annular helical fiber, comprises the following steps:

[0039] Material preparation: soak and clean the fiber substrate in ethanol and deionized water respectively, and dry it at room temperature for later use;

[0040] Preparation of conductive fiber: Dissolve conductive material in naphtha in proportion, ultrasonically treat for 0.5-2h, add rubber-based polymer material after magnetic stirring for 0.5-2h, continue stirring for 1-3h, and obtain conductive composite material solution; Put the fiber substrate into the above-mentioned conductive composite material solution for 5-10 minutes, and dry it under vacuum at 40-60°C to obtain conductive fibers;

[0041] Preparation of annular helical fiber unit: Dissolve the strain-sensitive material in naphtha according to the proportion, ultrasonically treat it for 1-3 hours, add the rubber-based polymer material after magnetic stirring fo...

Embodiment 1

[0045] S1: Soak the spandex fabric substrate and spandex fiber substrate in ethanol and deionized water respectively, clean them, and dry them at room temperature for later use;

[0046] S2: Dissolve 0.15g of carbon black and 0.15g of silver nanoparticles in naphtha, ultrasonically disperse for 0.5h, stir magnetically for 1h, add 1.5g of silicone rubber, and then perform magnetic stirring for 1.5h to obtain carbon black / silver nanoparticles particle / silicone rubber composite solution;

[0047] S3: put the spandex fiber substrate into the above carbon black / silver nanoparticle / silicone rubber composite material solution for 5 minutes, and vacuum-dry at 40°C to obtain conductive fibers;

[0048] S4: Dissolve 0.1g of graphene nanosheets and 0.05g of carbon nanotubes in naphtha, ultrasonically disperse them for 2h, and magnetically stir for 1.5h, then add 2g of silicone rubber, and then perform magnetic stirring for 2h to obtain graphene nanosheets / Carbon nanotube / silicone rubbe...

Embodiment 2

[0053] S1: Soak the spandex fabric substrate and spandex fiber substrate in ethanol and deionized water respectively, clean them, and dry them at room temperature for later use;

[0054] S2: Dissolve 0.15g of carbon black and 0.15g of silver nanoparticles in naphtha, ultrasonically disperse for 0.5h, stir magnetically for 1h, add 1.5g of silicone rubber, and then perform magnetic stirring for 1.5h to obtain carbon black / silver nanoparticles particle / silicone rubber composite solution;

[0055] S3: put the spandex fiber substrate into the above carbon black / silver nanoparticle / silicone rubber composite material solution for 5 minutes, and vacuum-dry at 40°C to obtain conductive fibers;

[0056] S4: Dissolve 0.1g of graphene nanosheets and 0.05g of carbon nanotubes in naphtha, ultrasonically disperse them for 2h, and magnetically stir for 1.5h, then add 2g of silicone rubber, and then perform magnetic stirring for 2h to obtain graphene nanosheets / Carbon nanotube / silicone rubbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com