Device for wirelessly monitoring turnout resistance

A wireless, turnout technology, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of affecting driving safety, squeezing lines, cumbersome and complicated installation, etc. Simple installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The features and principles of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

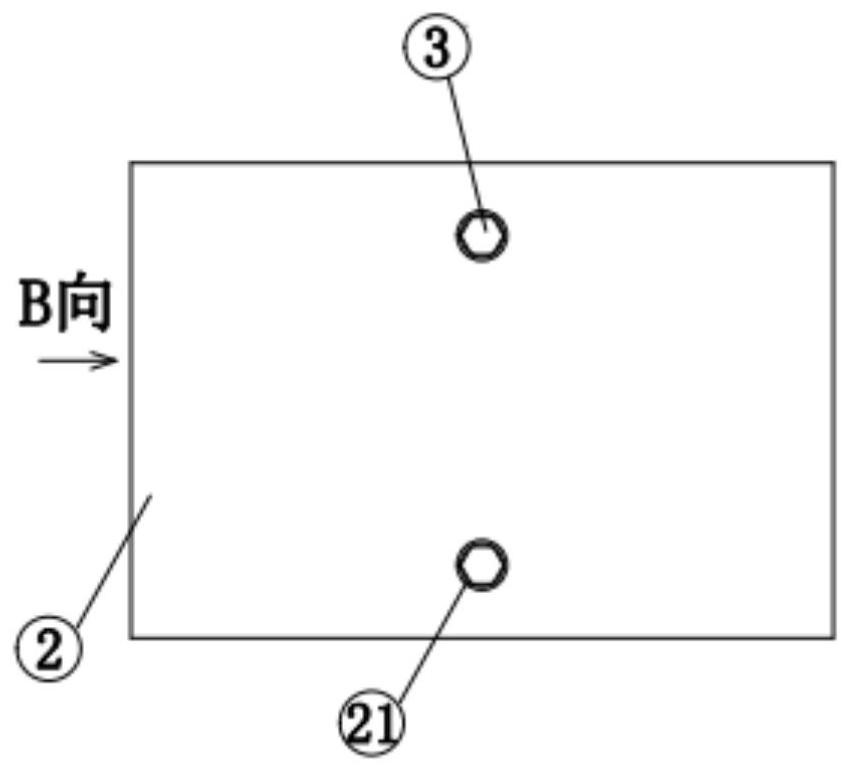

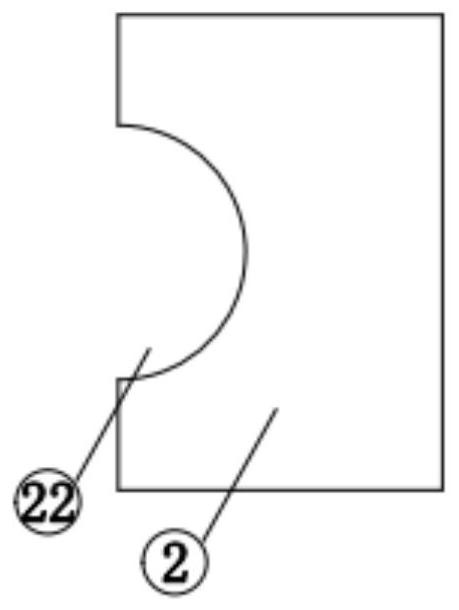

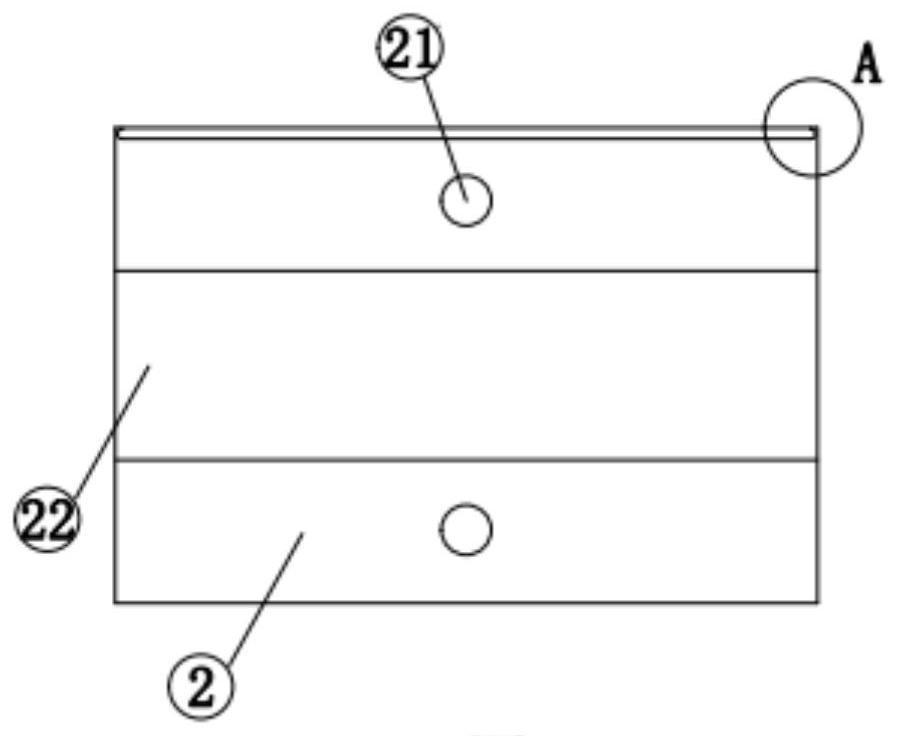

[0033] Such as Figure 1-Figure 7 As shown, the invention mainly consists of structural part A (1), structural part B (2), bolt (3), solar panel (4), stress sensor (101), vibration sensor (102), wireless communication module (103 ), a temperature sensor (104), a main control processing unit (105), a vibration energy conversion module (106), an energy collection management module (107), and a built-in energy storage module (108).

[0034] Through structural part A (1) and structural part B (2), the two are split structures made of rust-proof and corrosion-resistant metal materials, and the fixing bolts (3) are used to surround them to move them with the switch machine The rods (109) are reliably fixed togeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com