System and method for detecting heat treatment state of high-steel-grade thick-wall pipe fitting based on deep learning

A technology of thick-walled pipe fittings and deep learning, which is applied in neural learning methods, image data processing, computer parts, etc., can solve the problems of time-consuming and laborious, high inspection cost and cost, and unobjective and comprehensive inspection results, so as to avoid damage and waste, the effect of accurate inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

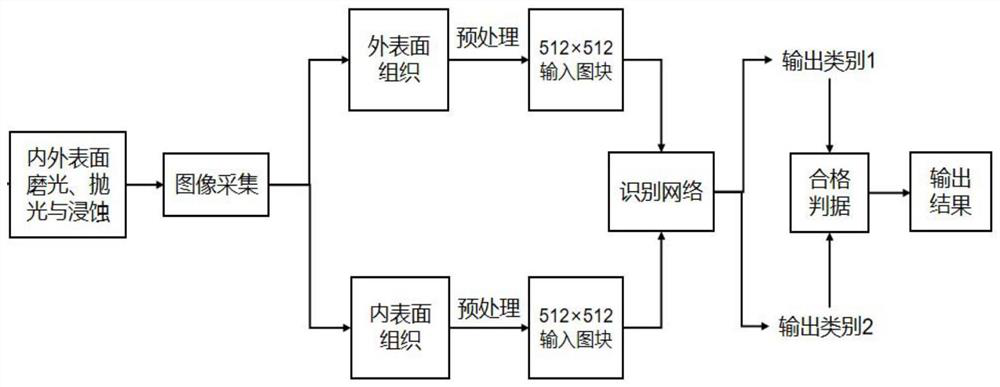

[0090] Applying the technology of the present invention to inspect the heat treatment state of a certain batch of tees with a specification of DN1000×900mm X70 thick wall, the specific steps are:

[0091] Step 1. Grinding, polishing and etching of the inner and outer surfaces of the pipe fittings

[0092] Use a portable electric metallographic grinder for rough grinding, fine grinding and polishing of the inner and outer surfaces of the tee. Until the polished part becomes a mirror surface. The above process needs to keep a certain flow of water as cooling fluid without interruption. Then use absorbent cotton dipped in 4% nitric acid alcohol solution to wipe the polished surface obtained by the above operation for 10 seconds until the original mirror surface color of the metal surface turns light gray.

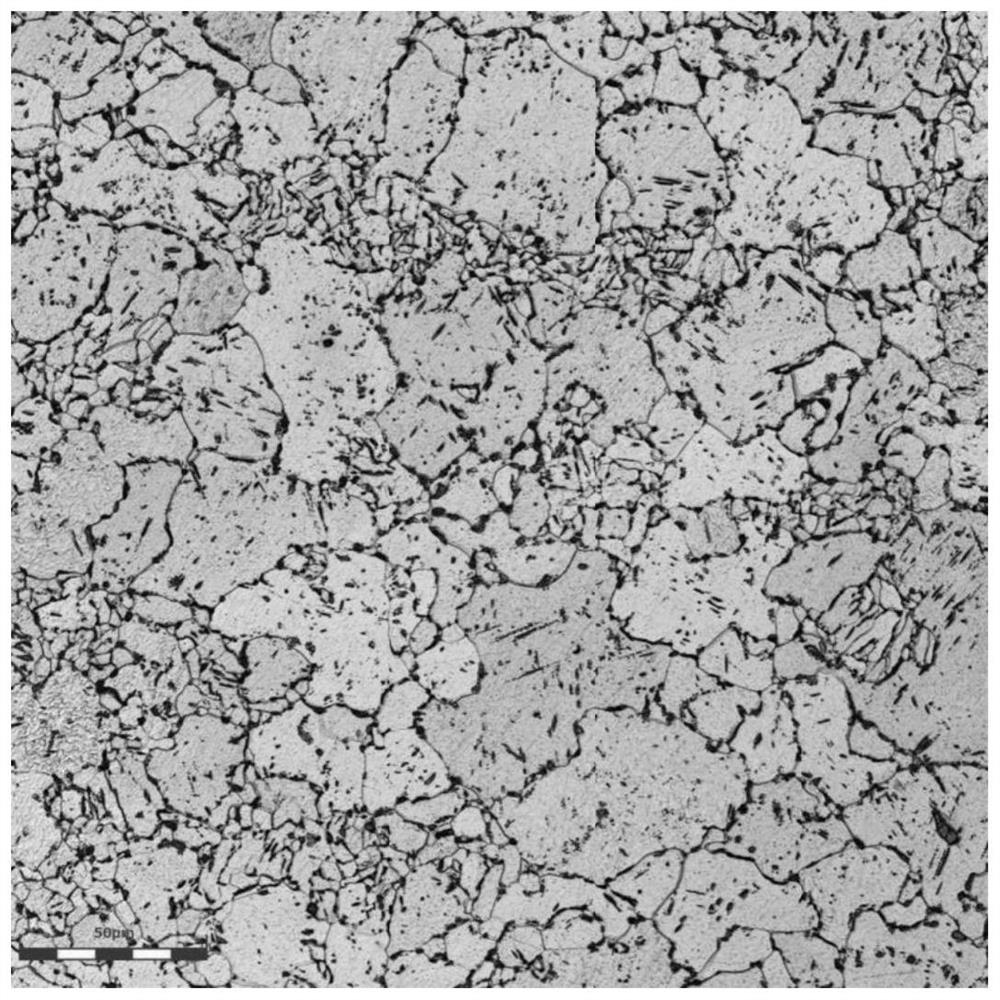

[0093] Step 2. Obtain the metallographic structure of the inner and outer surfaces of the tee

[0094] Use a portable metallographic microscope to observe the microstructur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com