A self-adaptive hole sowing intertillage fertilization vehicle with plant spacing and row spacing

A self-adaptive, fertilizing truck technology, applied in fertilizing devices, applications, planting methods, etc., can solve the problems of low operation efficiency, high growth distance requirements, increased soil moisture loss, etc., and achieves a simple and ingenious structure and a wide range of applications. , the effect of high fertilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

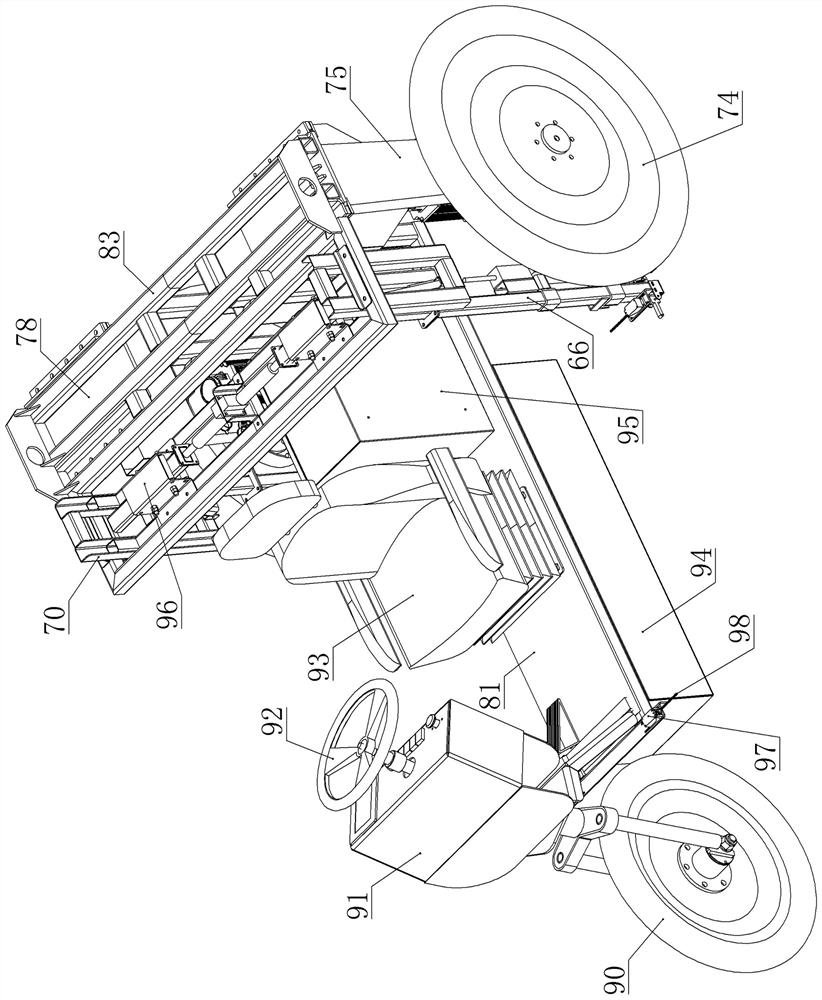

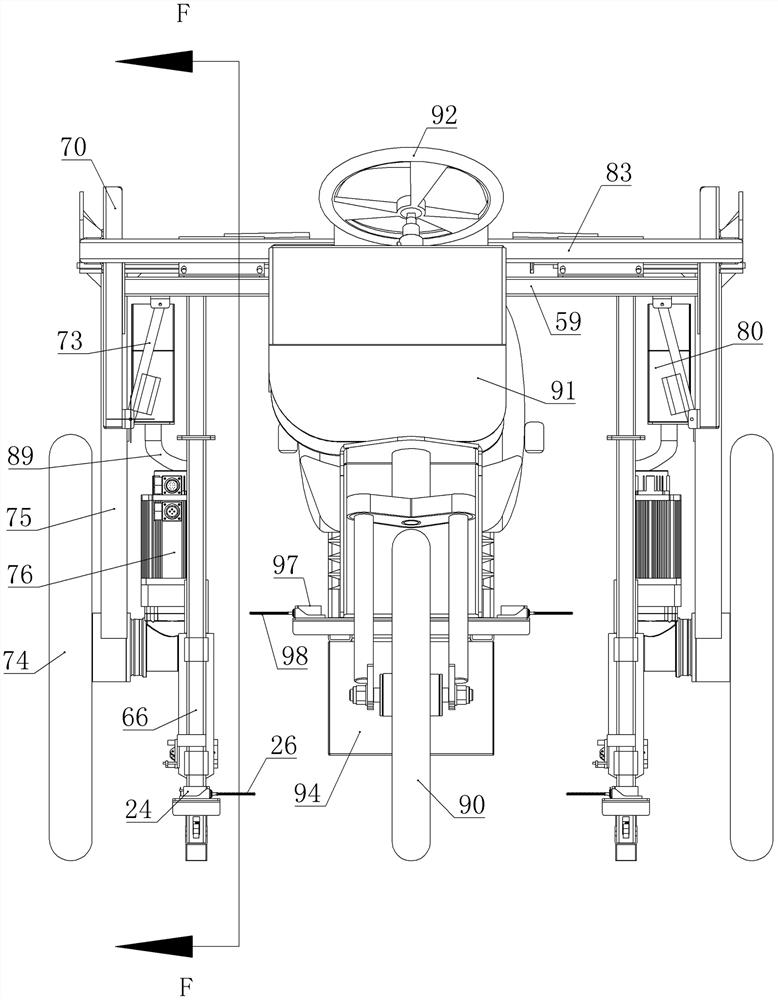

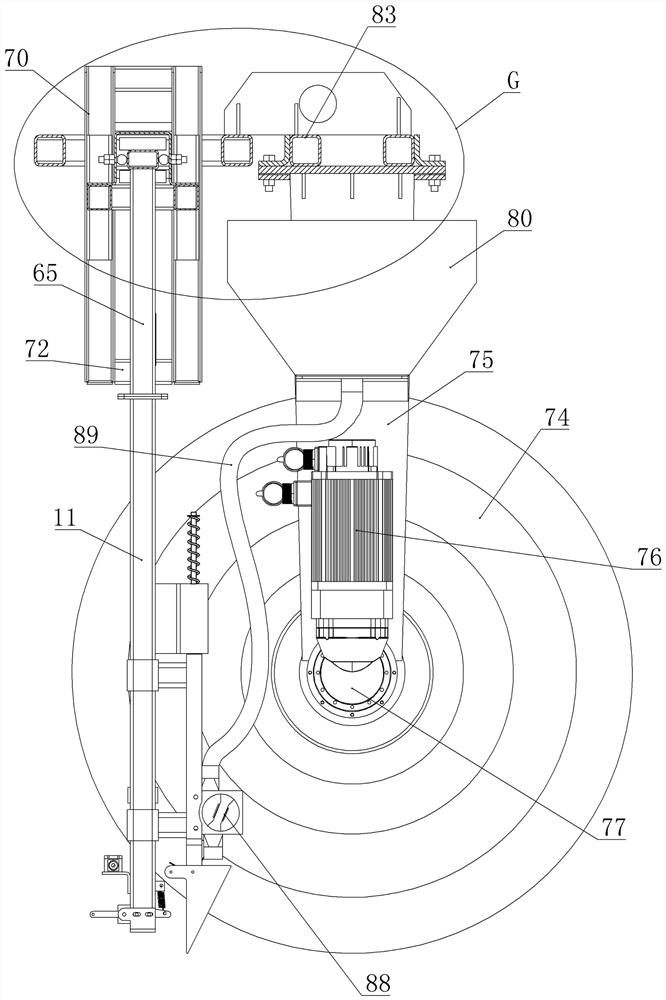

[0043] Embodiment one, see Figure 1-23 , a plant-to-plant and row-spacing self-adaptive hole sowing and intertillage fertilization vehicle, comprising a main frame with wheels and a fertilization device installed on the main frame;

[0044] The main vehicle frame includes a bottom frame arranged horizontally and vertically, a support vertical frame vertically fixed on the tail of the bottom frame, a main load horizontal frame horizontally and horizontally fixed on the top of the support vertical frame, and a steering wheel with a steering wheel is installed on the front end of the bottom frame. There is a control cabinet under the steering wheel, a battery pack is fixed on the lower surface of the chassis, and the battery pack supplies power to all electrical equipment on the entire fertilization vehicle, and a seat is fixed on the upper surface of the chassis. The rear of the chair is equipped with a power distribution box and an inverter fixed on the chassis, and a symmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com