Sectional production method of Litsea coreana insect tea

A production method, the technology of eagle tea, is applied in the segmented production field of eagle tea insect tea, which can solve the problems of low survival rate of tea-producing insects, uneven tea sand particles, and poor quality, so as to facilitate drilling and extraction The effect of uniform food and particles and reliable technical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

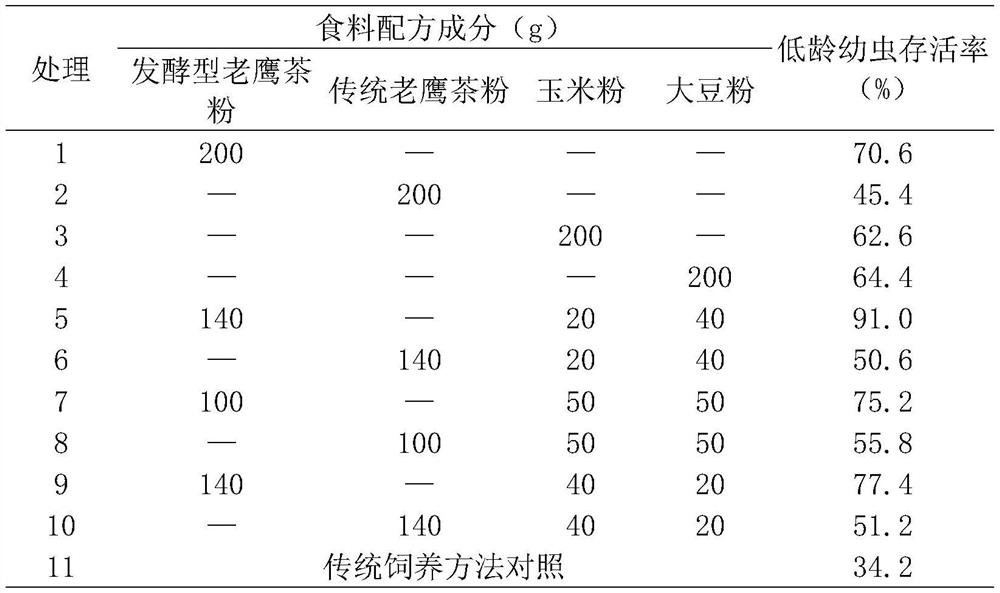

[0035] Study on the Effects of Different Formulas of Foodstuffs on the Survival Rate of Young Larvae of M.

[0036] In late April, the young shoots of Eagle tea that had germinated and grown for 45-50 days were picked in Meitan County, Guizhou Province as raw materials, withered for 24 hours, kneaded for 120 minutes, fermented at 25°C for 600 minutes, dried at 50°C and crushed, and passed through a 60-mesh sieve. Fermented eagle tea powder; take the commercially available traditional eagle tea, dry it, pulverize it, and pass through a 60-mesh sieve to get the traditional type eagle tea powder; grind corn and soybeans, pass through a 60-mesh sieve respectively, and prepare rice oyster according to the formula in Table 1 As for the food for young larvae of borers, put the food for young larvae that has been mixed and prepared in a container, and take it out after steam sterilization at 121° C. and a pressure of 0.1 MPa for 40 minutes.

[0037]Place 30 adults in an insect raising...

Embodiment 2

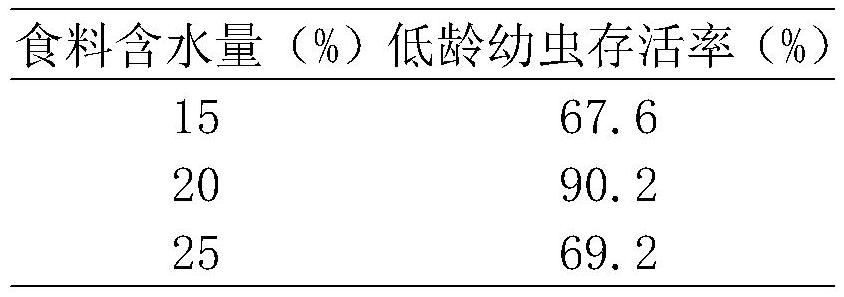

[0050] Study on the Effects of Diet with Different Moisture Content on the Survival Rate of Young Larvae of M.

[0051] Put 30 adults of the rice borer into an insect raising tank (10 cm in diameter and 20 cm in height), cover the top of the insect raising tank with 100-mesh nylon gauze, place the insect raising tank upside down in a clean container, and shake it gently to obtain eggs. With fermented eagle tea powder, corn flour and potato flour mass ratio in embodiment 1, the food material that is 7: 1: 2 is carried out to cultivating the larvae of the rice stem borer: 200 grains of gained worm eggs are put into 200g food material, and food material is set Water content is 15%, 20%, 25% three treatments. To be hatched and cultivated until the larva head width is about 1.2mm, reaching the 3rd instar larvae, record the number of 3rd instar larvae in each treatment, calculate the survival rate (%) of the young instar larvae, and repeat 5 times for each treatment.

[0052] Survi...

Embodiment 3

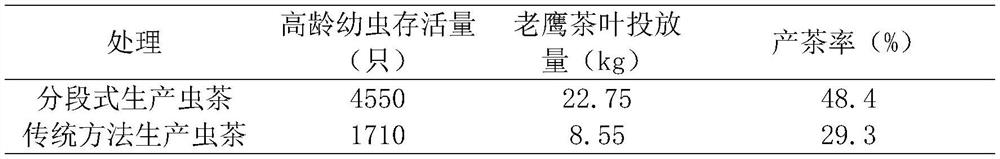

[0060] Study on the Influence of Staged Cultivation of Tea-producing Insects on the Yield of Insect Tea

[0061] The preparation of food for the young larvae (1-2 instars) of the rice borer: the young shoots of eagle tea that have germinated and grown for 45-50 days in spring are used as raw materials, withered for 24 hours, kneaded for 120 minutes, fermented at 25°C for 600 minutes, dried at 50°C over a slow fire, and crushed , through a 60-mesh sieve to obtain fermented eagle tea powder; then crush the corn and soybeans, pass through a 60-mesh sieve respectively, and prepare the food for young larvae according to the ratio of fermented eagle tea powder, corn flour and soybean flour in a ratio of 7:1:2.

[0062] Foodstuffs for the old larvae of the rice moth (3-5 instars): traditional eagle tea fragments that have been sieved through a 120-wire sieve.

[0063] The food of the above-mentioned young larvae and senior larvae of the rice moth was packed in a container, steam ster...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com