Ready-to-eat non-fried noodle leaves brewed with boiled water and preparation method of ready-to-eat non-fried noodle leaves

A non-fried noodle technology, which is applied in the field of non-fried noodle and its preparation, can solve the problems of no noodle production technology, inability to satisfy consumers for brewing and eating in boiling water, and no patent publications have been found. unique effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the instant non-fried noodle leaves prepared by brewing boiling water as described above, the steps are as follows:

[0029] Step 1, kneading the dough, maturing the kneaded dough for 15-20 minutes and then compound rolling to obtain a 0.80-0.85mm dough piece;

[0030] Step 2. Cook the noodles obtained in step 1 for 200-240s at a temperature of 98-100°C and a steam pressure of 0.02MPa-0.03MPa;

[0031] Step 3. Dry the surface moisture of the dough sheet obtained in step 2 at room temperature under the condition that the wind speed is 3-5m / s and the time is 1-2min;

[0032] Step 4. Cut the dough pieces obtained in step 3 into long dough pieces through a noodle knife, and then cut them into noodle leaves with a width of 2 cm and a length of 6-7 cm through a horizontal cutter; figure 1 with figure 2 shown;

[0033] Step 5, drying the face leaf obtained in step 4, the drying condition is 75°C, the wind speed on the face leaf surface is 2-3m / s, ...

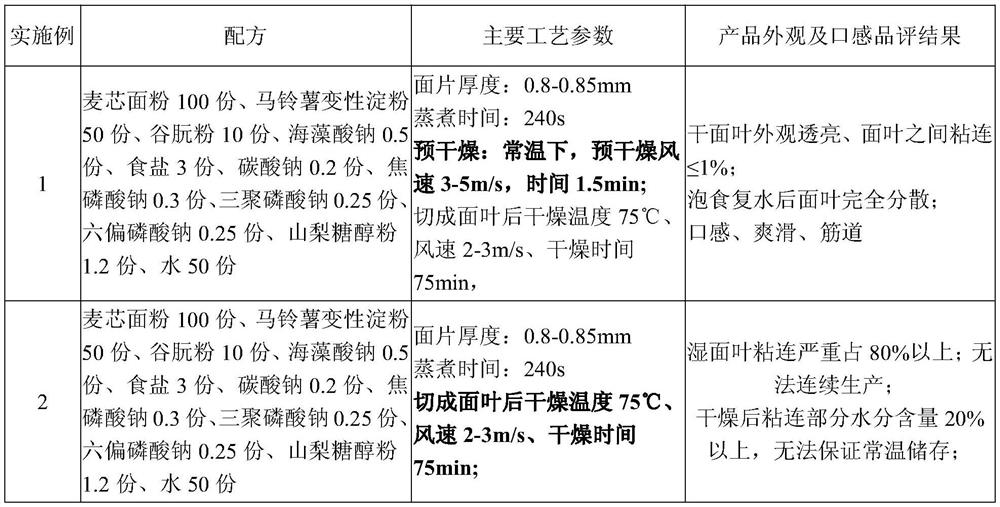

Embodiment 1

[0041] A kind of instant non-fried noodle leaves brewed in boiling water, its raw materials and parts by weight are:

[0042] Wheat core flour 100 parts, potato modified starch 50 parts, gluten flour 10 parts, sodium alginate 0.5 parts, salt 3 parts, sodium carbonate 0.2 parts, sodium pyrophosphate 0.3 parts, sodium tripolyphosphate 0.25 parts, sodium hexametaphosphate 0.25 parts, 1.2 parts of sorbitol powder, 50 parts of water.

[0043] The preparation method of the instant non-fried noodle leaves prepared by brewing boiling water as described above, the steps are as follows:

[0044] Step 1. According to the preferred formula and noodles, compound rolling after aging to obtain 0.80-0.85mm noodles;

[0045] Step 2. Steam the noodles obtained in step 1 for 240s under the conditions of a steamer temperature of 98-100°C and a steam pressure of 0.02MPa-0.03MPa;

[0046] Step 3. Dry the surface moisture of the dough sheet obtained in step 2 under the conditions of a wind speed o...

Embodiment 2

[0051] A kind of ready-to-eat non-fried noodles prepared by boiling water, its raw materials and parts by weight are the same as those in Example 1.

[0052] The preparation method of the instant non-fried noodle leaves prepared by brewing boiling water as described above, the steps are as follows:

[0053] Step 1. According to the preferred formula and noodles, compound rolling after aging to obtain 0.80-0.85mm noodles;

[0054] Step 2. Steam the noodles obtained in step 1 for 240s under the conditions of a steamer temperature of 98-100°C and a steam pressure of 0.02MPa-0.03MPa;

[0055] Step 3. Pass the dough sheet obtained in step 3 directly through the noodle knife without drying, the dough sheet cannot be completely cut off, and the adhesion rate accounts for more than 80%;

[0056] Step 4, drying the face leaf obtained in step 4, the drying condition is 75°C, the wind speed on the face leaf surface is 2-3m / s, and the drying time is 75min.

[0057] Conclusion: The adhes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com