Method for recovering ilmenite from iron separation tailings

A technology for recovering titanium and tailings, applied in flotation, solid separation, high gradient magnetic separator, etc., can solve the problems of insufficient utilization of resources, low recovery rate of titanium concentrate, and large environmental pollution, saving equipment resources , Improve the grade, reduce the effect of sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

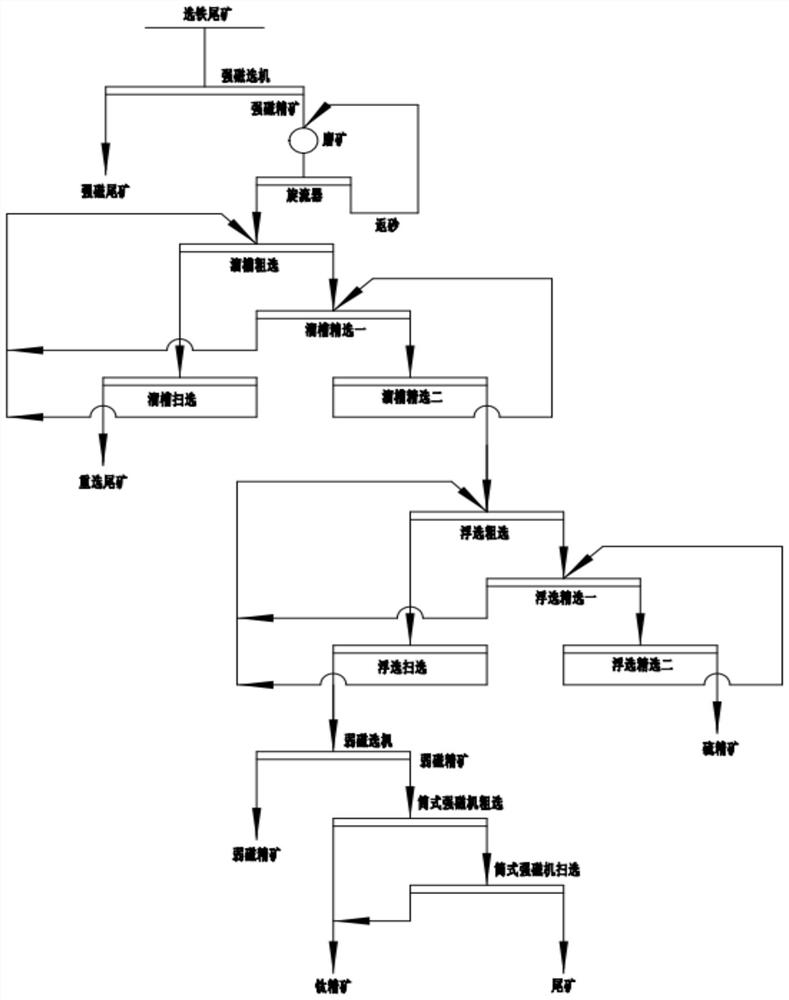

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 reclaims the method for ilmenite from iron dressing tailings

[0057] Taking a concentrator in Panzhihua as an example, the concentrator deals with locally mined vanadium-titanium magnetite. The mass proportion of Fe in the raw ore is 19-22%, and TiO 2 The mass proportion of 4.54%, the mine is characterized by rich olivine pyroxene, processed as follows:

[0058] S1. The above-mentioned raw ore is carried out with a vertical ring type high-gradient strong magnetic machine for strong magnetic tailing, and the magnetic field strength is 8000Gs to obtain a strong magnetic concentrate and a strong magnetic tailing. The grade of the strong magnetic concentrate is 8%, and the concentration of the strong magnetic tailing TiO 2 % grade can be controlled below 2%;

[0059] S2. Use a ball mill to perform closed-circuit grinding on the obtained strong magnetic concentrate until the content of the -0.074mm particle size raw material is 40%, and then classify and scre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com