Patents

Literature

42results about How to "Improve recovery yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

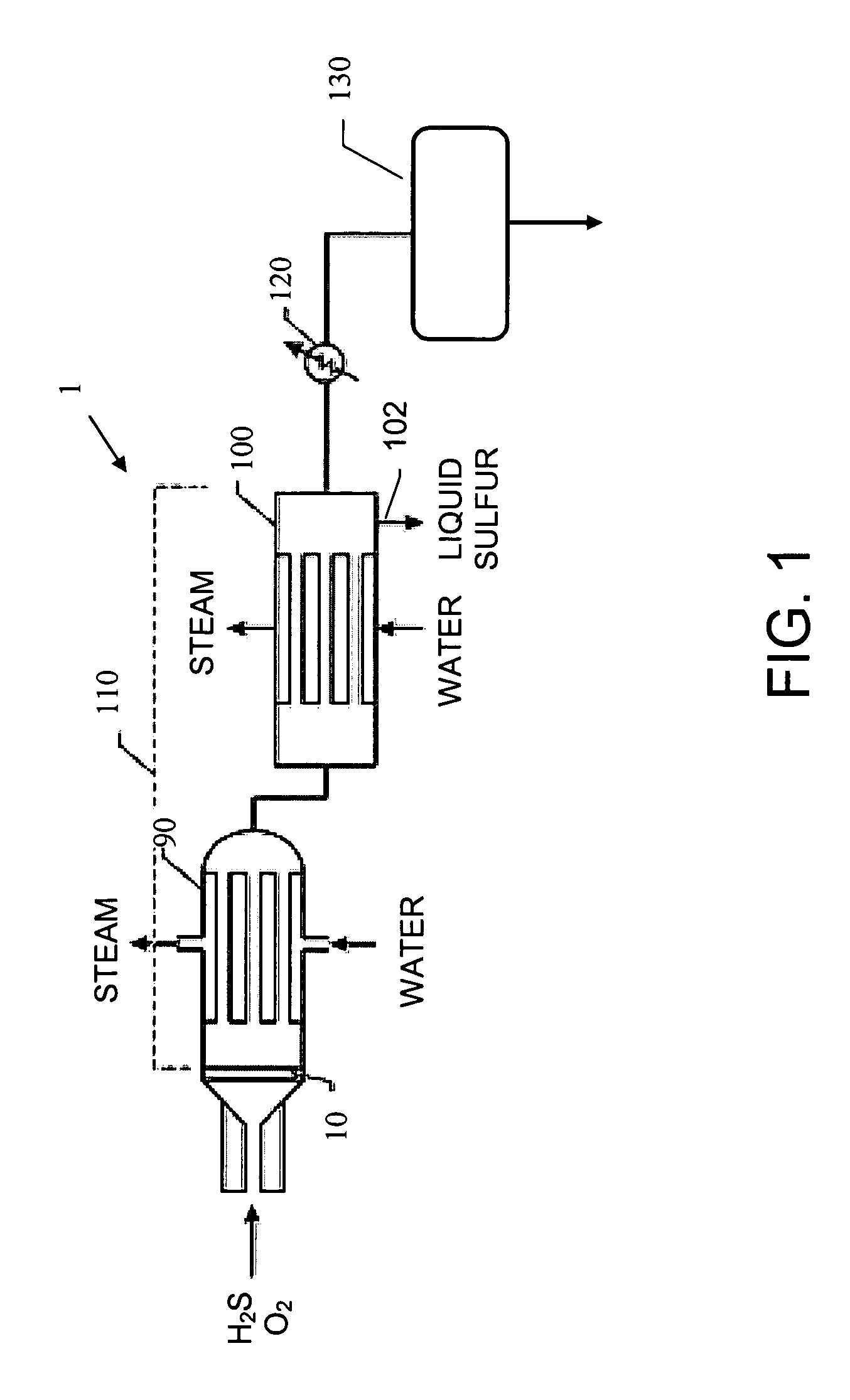

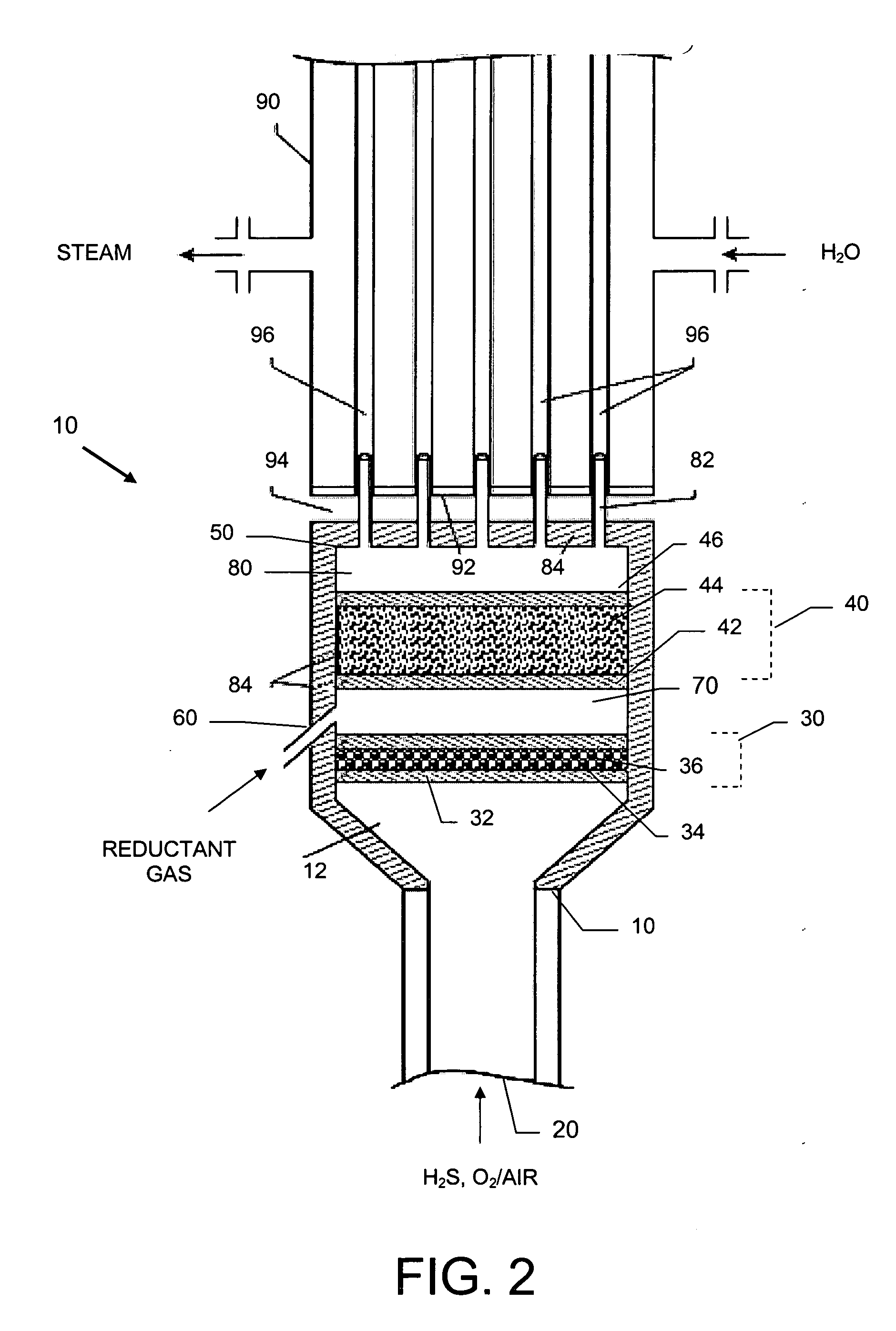

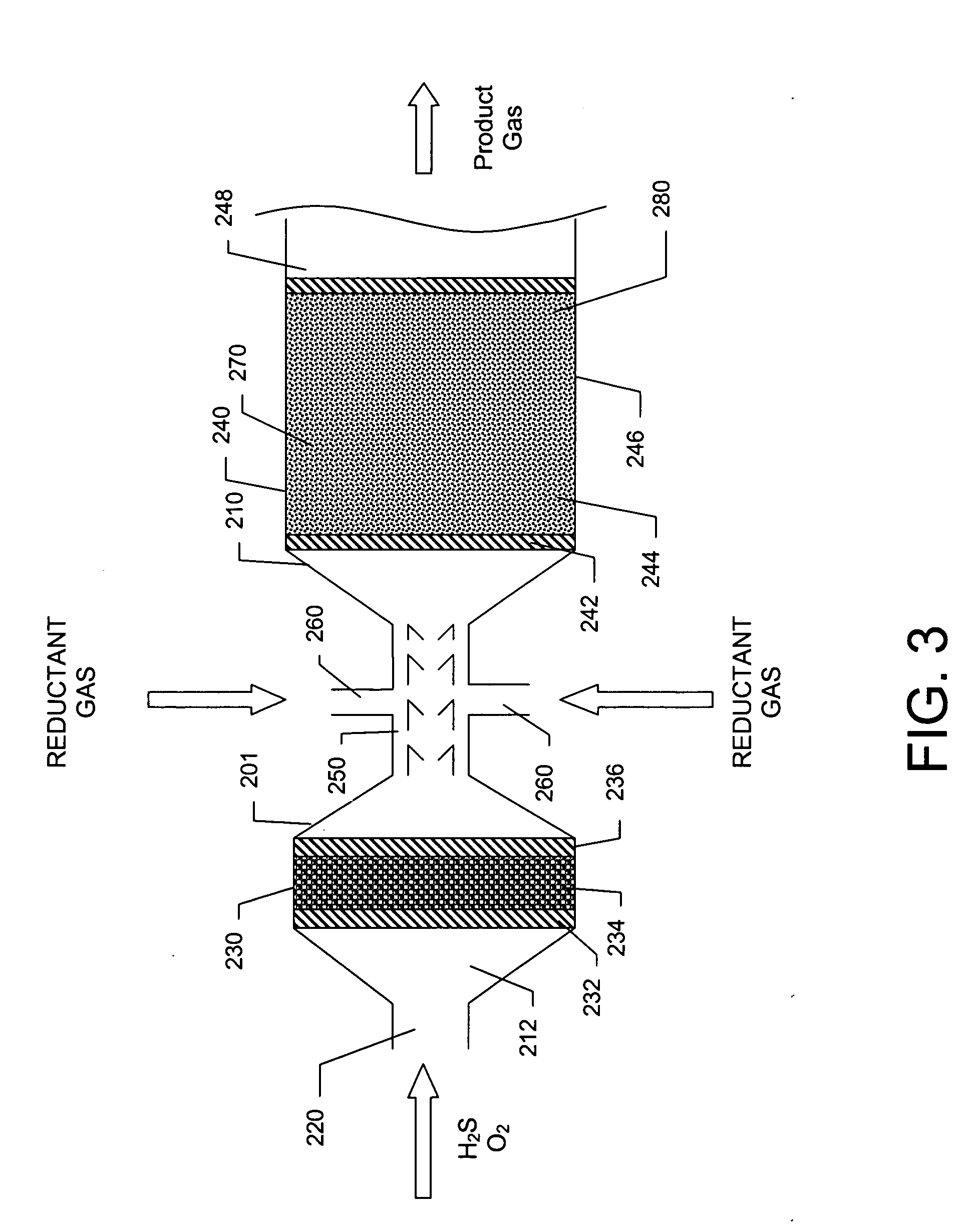

Two-stage catalytic process for recovering sulfur from an H2S-containing gas stream

InactiveUS20050180914A1Easy to operateImprove stabilityCombination devicesPhysical/chemical process catalystsPartial oxidationSulfur

Apparatus and process for recovering elemental sulfur from a H2S-containing waste gas stream are disclosed. The apparatus preferably comprises a first reaction zone for carrying out the catalytic partial oxidation of H2S, a second reaction zone for the catalytic partial reduction of any incidental SO2 produced in the first reaction zone, and a cooling zone including a sulfur condenser. According to a preferred embodiment of the process, a mixture of H2S and O2 contacts a catalyst in the first reaction zone very briefly (i.e, less than about 200 milliseconds) producing primarily S0 and H2O. Some SO2 is also present in the first stage product gas mixture. A reductant gas (e.g. CO, or CH4 or natural gas) is fed together with the first stage product gas mixture to a second catalytic reaction zone where the partial reduction of the SO2 component to elemental sulfur and CO2 is carried out.

Owner:CONOCOPHILLIPS CO

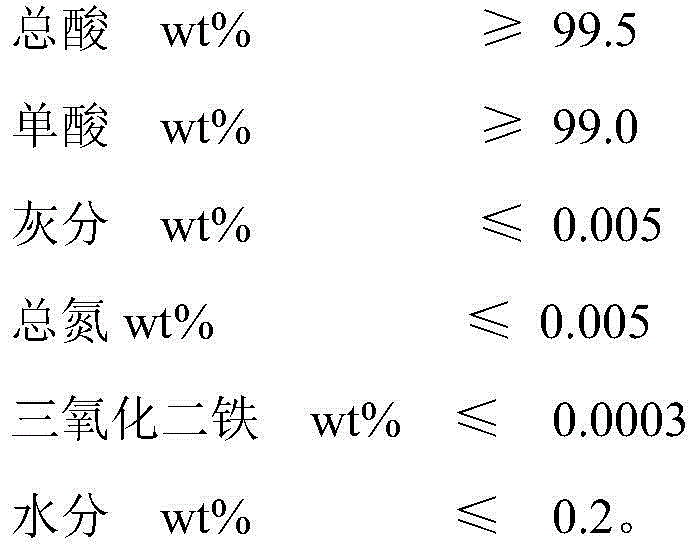

Recycling method of purifying, refining and crystallizing mother liquor of dodecanedioic acid

ActiveCN104447280AInhibition of esterificationSolve complexityOrganic compound preparationHydroxy compound preparationTotal nitrogenSolvent

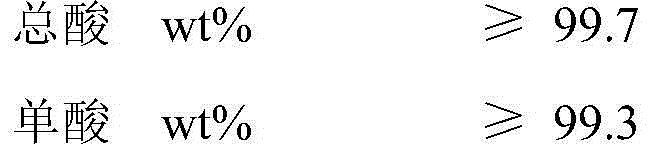

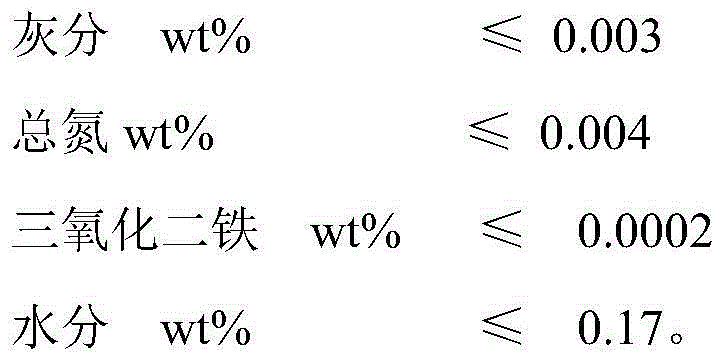

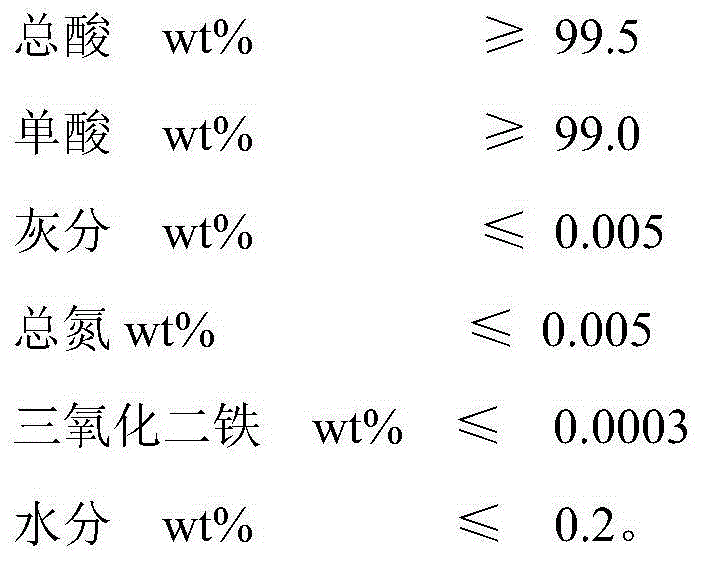

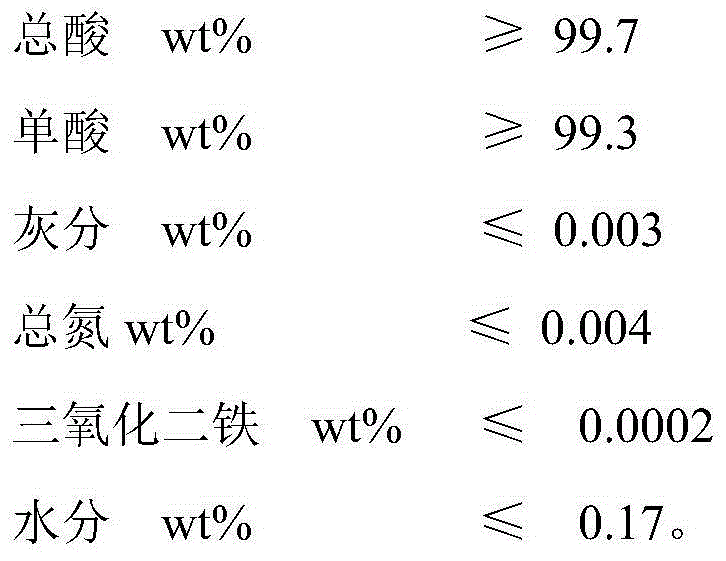

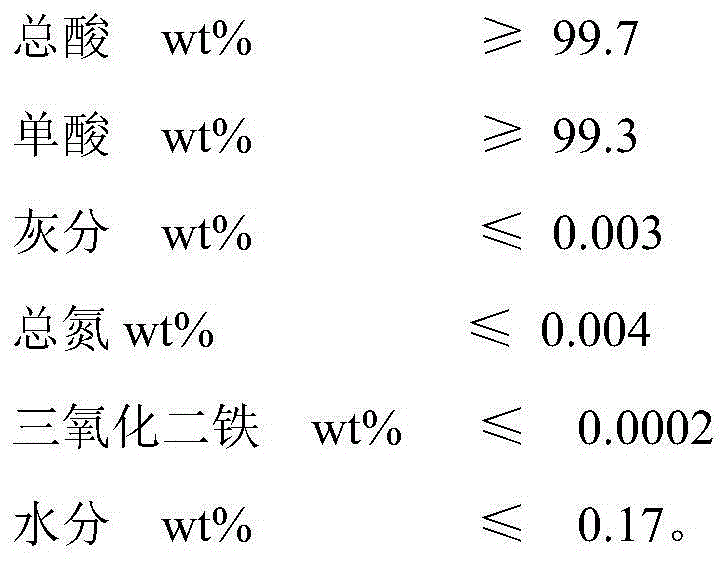

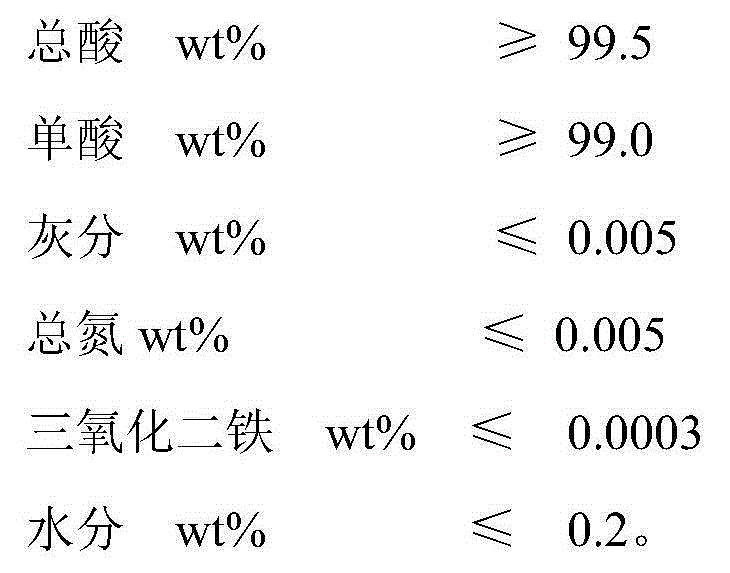

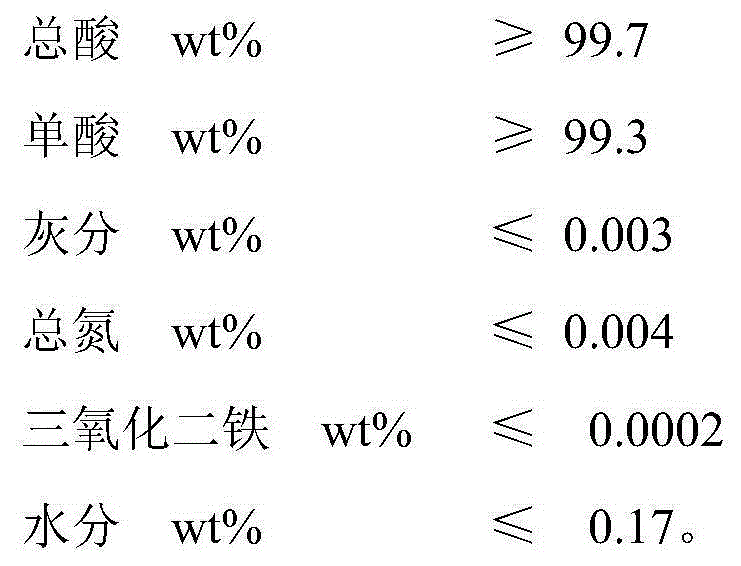

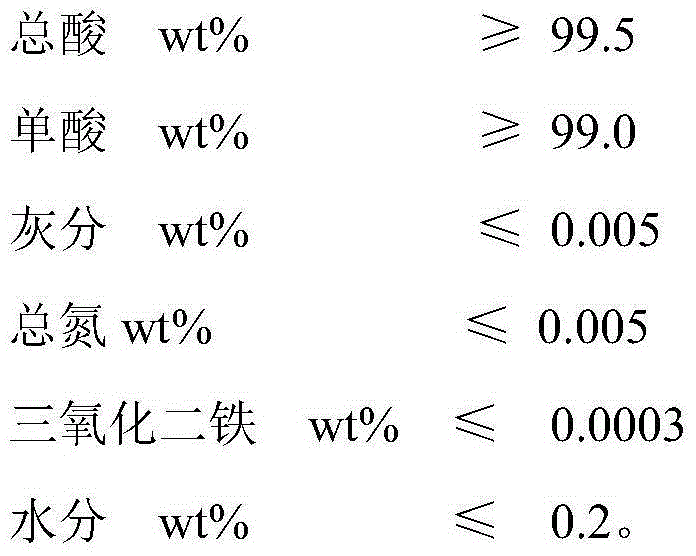

The invention provides a recycling method of mother liquor purifying, refining and crystallizing mother liquor of dodecanedioic acid, and belongs to the separation treatment method of non-acyclic dicarboxylic acid containing 12 carbon atoms. The recycling method comprises the steps of (1) recovering a solvent which is methanol; (2) distilling to dissolve and dilute materials residual at the bottom of a kettle; (3) performing acidification under a high temperature, and crystallizing; (4) drying. The recycling method of mother liquor purifying, refining and crystallizing mother liquor of dodecanedioic acid has the advantages that the recovered dodecanedioic acid product has a good color and luster and is of high purity, and moreover, the recovery yield is raised, the device investment is saved, the operation is simple and convenient, the resource can be saved, and the environment is protected; the recovery yield of the dodecanedioic acid product is not less than 97.0%; the product quality meets the technical indexes that the total acid is not less than 99.7wt% (percentage by weight), single acid is not less than 99.3wt%, ash content is not greater than 0.003wt%, the total nitrogen is not greater than 0.004wt%, ferric oxide is not greater than 0.0002wt%, and water content is not greater than 0.17wt%.

Owner:山东广通新材料有限公司

Recycling method of long carbon chain binary acid purification and refining crystallization mother liquor

ActiveCN104447274AImprove solubilityHigh recovery rateOrganic compound preparationHydroxy compound preparationSolventChemistry

The invention discloses a recycling method of long carbon chain binary acid purification and refining crystallization mother liquor, and belongs to a separation treatment method of acyclic dicarboxylic acid with 12 carbon atoms. The method comprises the following operation steps: (1) recovering solvent methanol; (2) dissolving and diluting a residual material at the bottom of a distillation kettle; (3) performing high-temperature acid-out crystallization; (4) drying. The recycling method of the long carbon chain binary acid purification and refining crystallization mother liquor has the advantages that the recovered long carbon chain binary acid product has good color, high purification and high recovery yield, equipment investment is saved, the operation is easy and convenient, the resource is saved, and environment protection is facilitated. By using the method, the long carbon chain binary acid recovery rate is greater than or equal to 97.0 percent. The product quality reaches the following technical indexes that the total acid is greater than or equal to 99.7 percent by weight, the single acid is greater than or equal to 99.3 percent by weight, the ash content is smaller than or equal to 0.003 percent by weight, the total nitrogen is smaller than or equal to 0.004 percent by weight, the ferric oxide is smaller than or equal to 0.0002 percent by weight, and the moisture is smaller than or equal to 0.17 percent by weight.

Owner:山东广通新材料有限公司

Method for recovering highly pure potassium chloride from fluorination reaction byproduct

ActiveCN106006679ASimple processConducive to downstream utilizationAlkali metal halide purificationPotassium fluoridePotassium

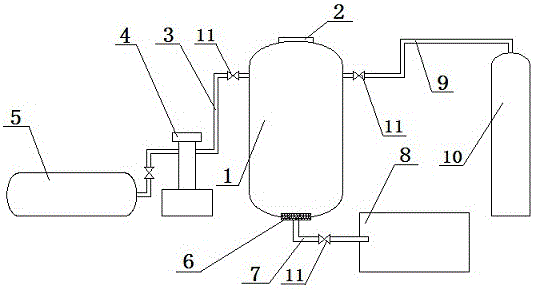

The invention provides a method for recovering highly pure potassium chloride from a fluorination reaction byproduct. The method comprises the following steps: 1, preprocessing: carrying out heat treatment on the fluorination reaction byproduct to remove adhered organic matter wastes; 2, dissolving and separating: placing a preprocessed solid mixture in a separation device, introducing liquid ammonia to dissolve potassium fluoride in the preprocessed solid mixture to form a mixed solution, filtering the mixed solution to obtain a filter cake which is crude primary potassium chloride and a filtrate which is a liquid ammonia solution of potassium chloride, squeezing the filtrate, introducing the squeezed filtrate to a pressure reducing chamber, and reducing the pressure to normal pressure to gasify the liquid ammonia in the filtrate in order to obtain a pure potassium fluoride solid; 3, washing: adding a mixed solvent A to the crude primary potassium chloride, washing the crude primary potassium chloride to remove residual trace impurities, and filtering the washed crude primary potassium chloride to obtain crude secondary potassium chloride; and 4, purifying: adding deionized water to the crude secondary potassium chloride, heating the deionized water to dissolve the crude secondary potassium chloride in order to prepare a saturated solution, cooling the saturated solution to room temperature, adding a solvent B to carry out re-crystallization, filtering the obtained solution, washing obtained crystals with the solvent b, and drying the washed crystals to obtain highly pure potassium chloride.

Owner:RONGCHENG QINGMU CHEM MATERIALS

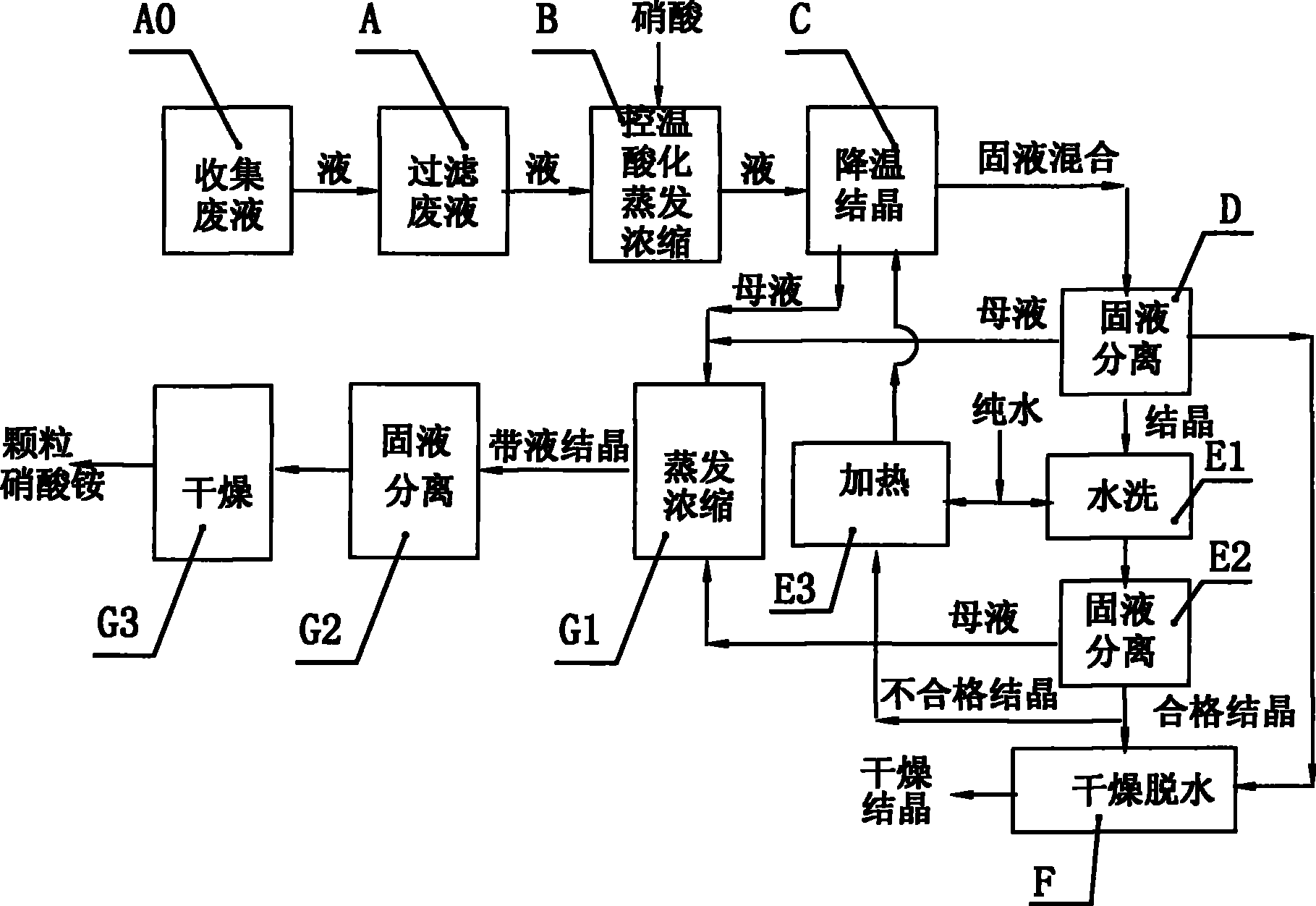

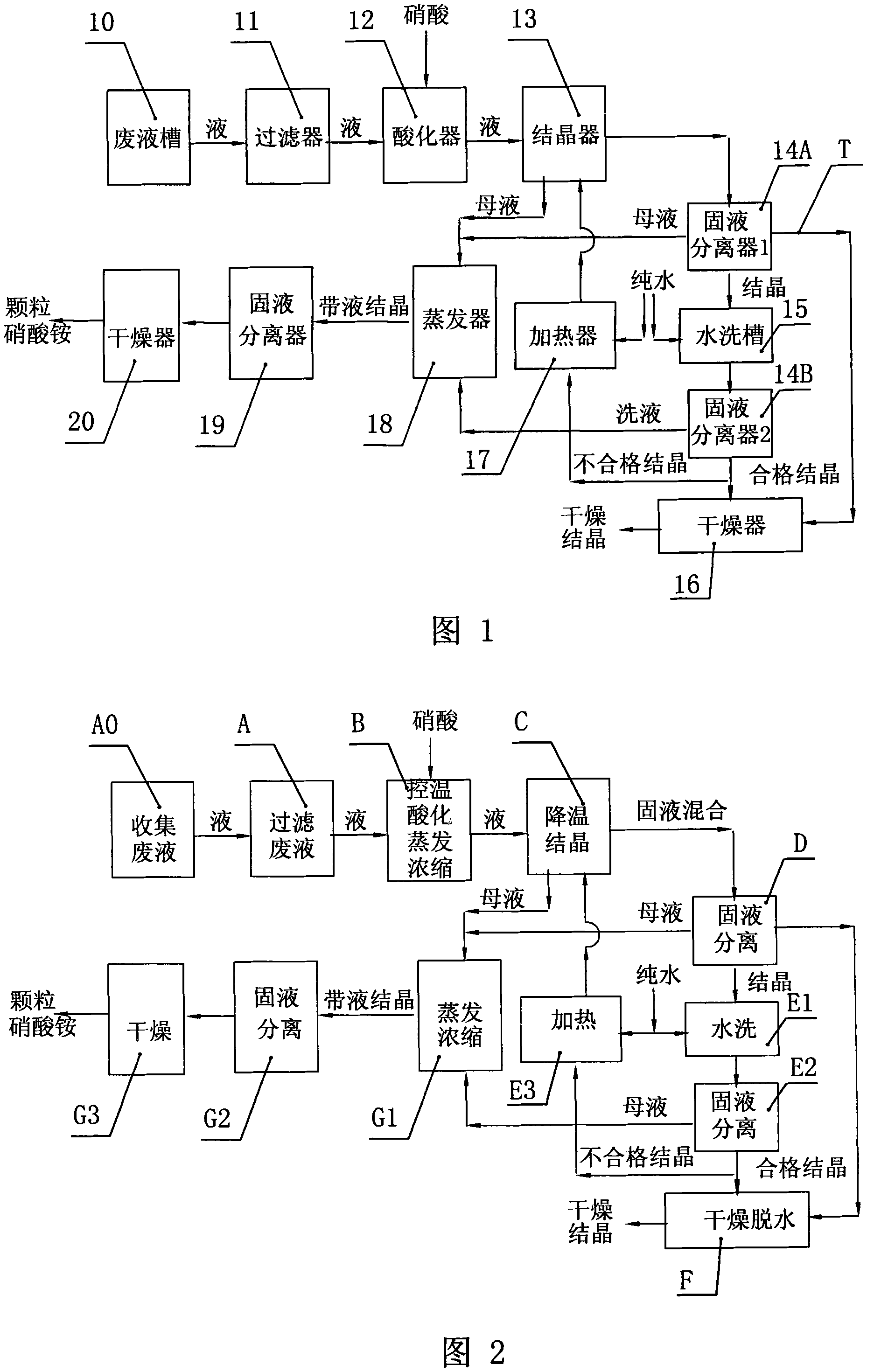

Method for recycling waste liquor of ammonium hexanedioic acid and recycling system thereof

InactiveCN101219946ASimple processGood effectOrganic compound preparationCarboxylic compound separation/purificationAdipic acid / AmmoniumCapacitance

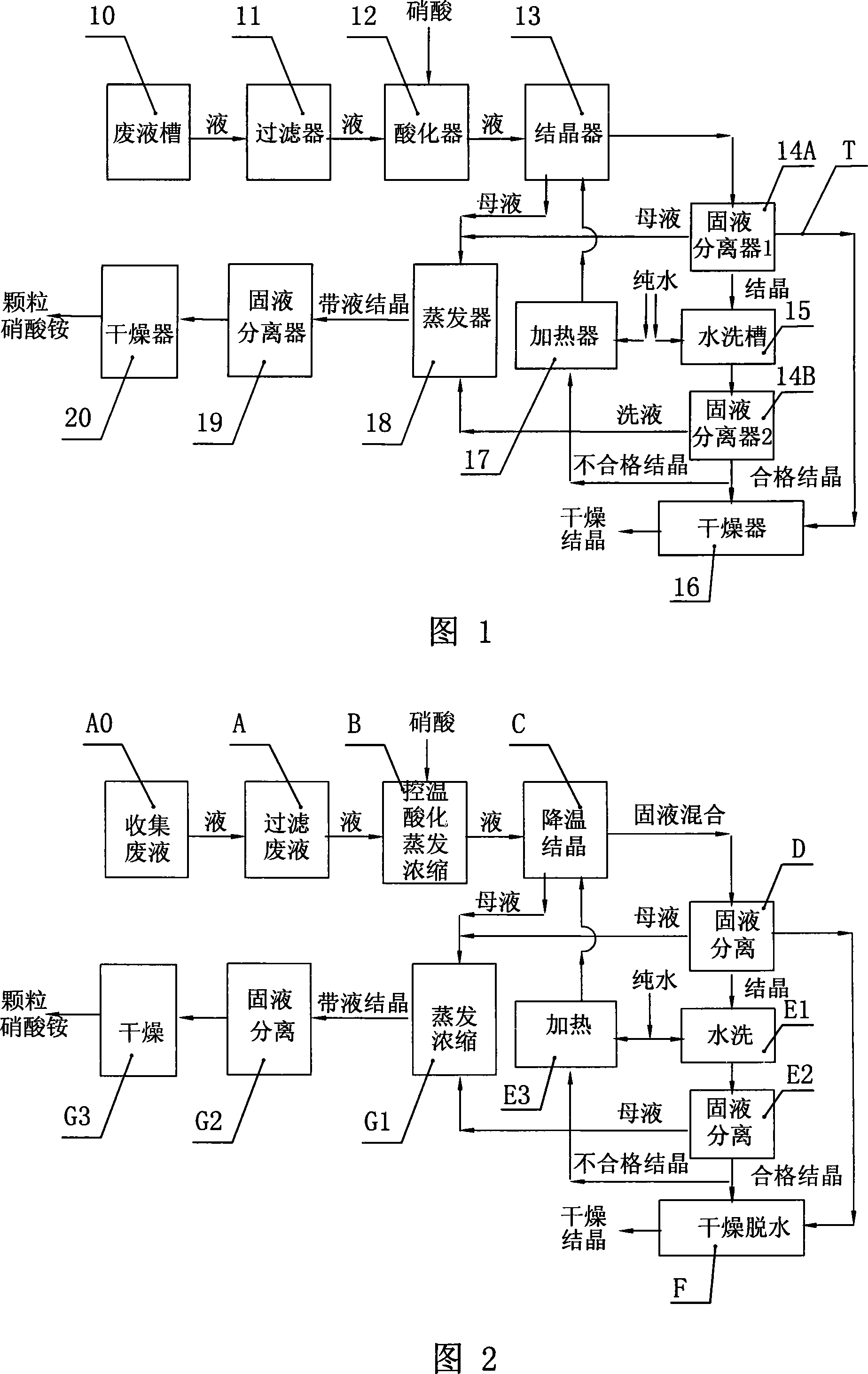

The invention relates to a method and a system for treating and recovering adipic acid ammonium waste liquid and the recovering method comprises the following steps: A. filtering the solid impurities in the waste liquid, B. controlling the temperature of the filtered waste liquid and acidizing the filtered waste liquid, C. decreasing the temperature of the acidulated waste liquid and crystallizing the acidulated waste liquid, D. collecting adipic acid crystal after solid-liquid separation, E. washing to get the adipic acid crystal and collecting the adipic acid crystal after solid-liquid separation. The recovering method and recovering system of the invention have the following advantages: being able to acquire purified adipic acid with standard capacitance; being able to be recycled used in the industries such as an electrolytic capacitor, etc., having a simple and efficient technique and obvious economical benefit and environment protection effect.

Owner:RUYUAN YAO AUTONOMOUS COUNTY DONGYANGGUANG FORMED FOIL CO LTD

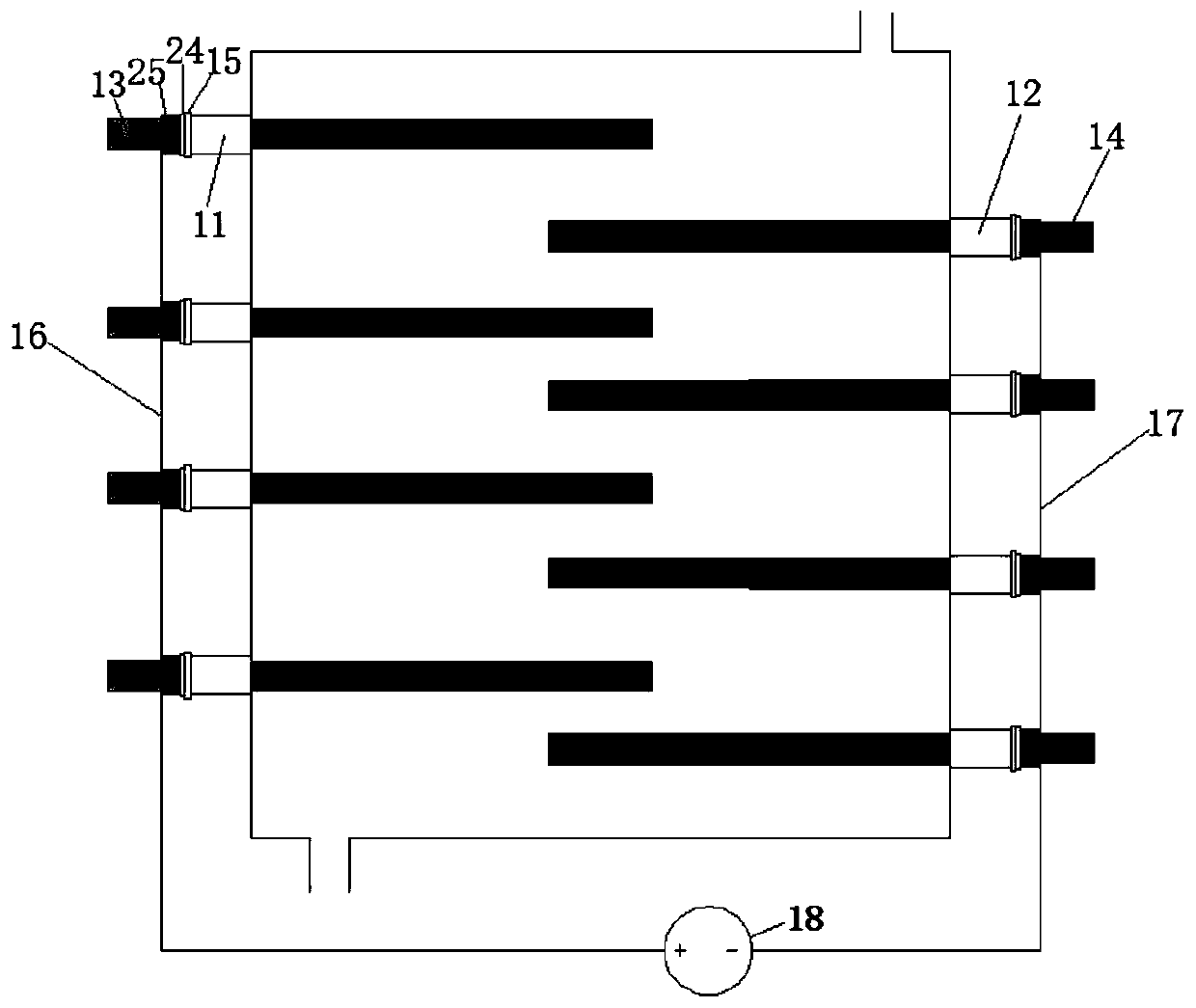

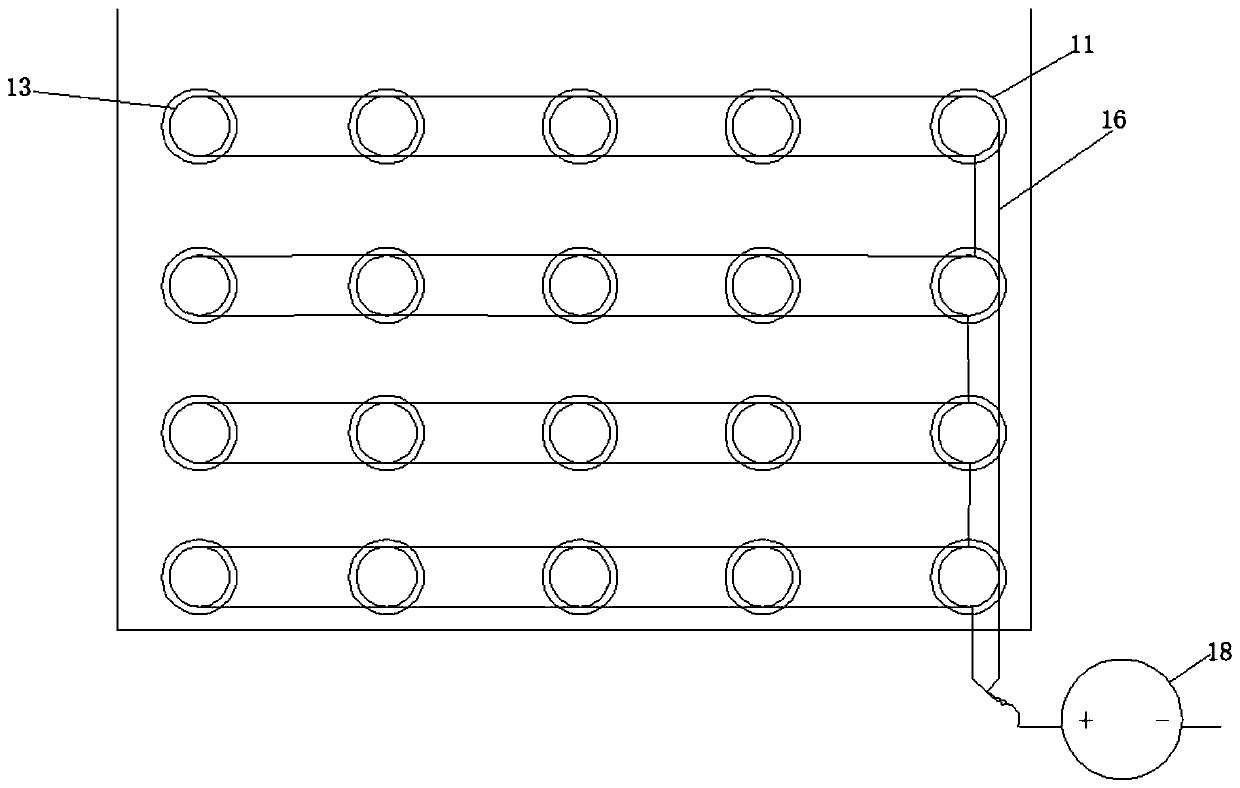

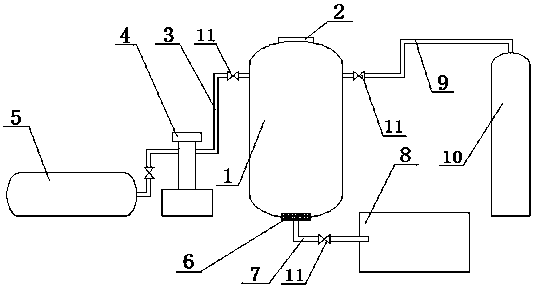

Electrochemical reaction system capable of realizing high-efficiency recovery of nitrogen and phosphorus

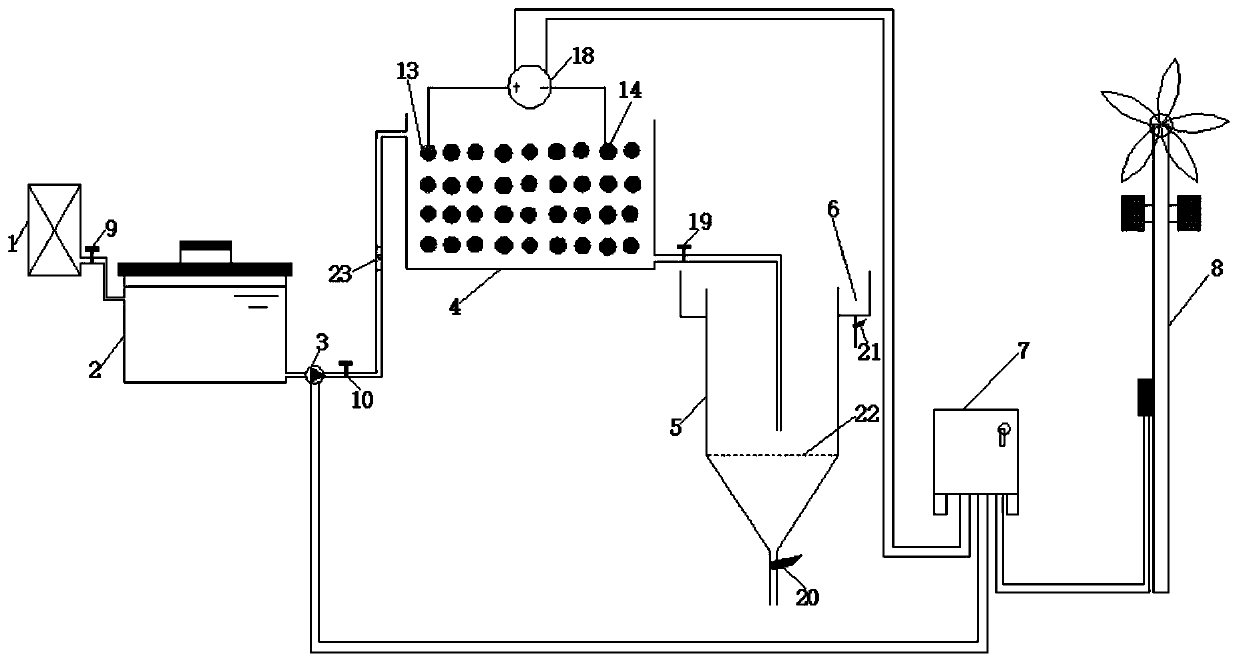

ActiveCN110357219AReduce flow rateAvoid short circuitElectrolysis componentsWater contaminantsElectrochemical responseElectrolysis

The invention discloses an electrochemical reaction system capable of realizing high-efficiency recovery of nitrogen and phosphorus, belonging to the field of water treatment in environmental engineering. The electrochemical reaction system comprises a pretreatment unit, a feeding box, a lift pump, an electrolytic reaction tank, a struvite settling tank and a liquid storage tank. Anode magnesium alloy rods and cathode stainless steel rods are parallel to each other and arranged in a staggered manner and do not contact with each other, and the electrodes are perpendicular to the flow directionof feed liquid; the sum of the length of each anode magnesium alloy rod part located inside the electrolytic reaction tank and the length of one corresponding cathode stainless steel rod part locatedinside the electrolytic reaction tank is greater than the distance between the two side walls of the electrolytic reaction tank, so the flow rate of the feed liquid is reduced due to obstruction of the anode magnesium alloy rods and the cathode stainless steel rods. The electrochemical reaction system of the invention adopts an electrochemical technology to treat phosphorus-and-ammonia-containingwastewater, and the whole system can realize integrated automatic operation and has the advantages of energy conservation, high efficiency, low running cost, simple operation, etc.

Owner:HUBEI MEICHEN ENVIRONMENTAL PROTECTION CO LTD +1

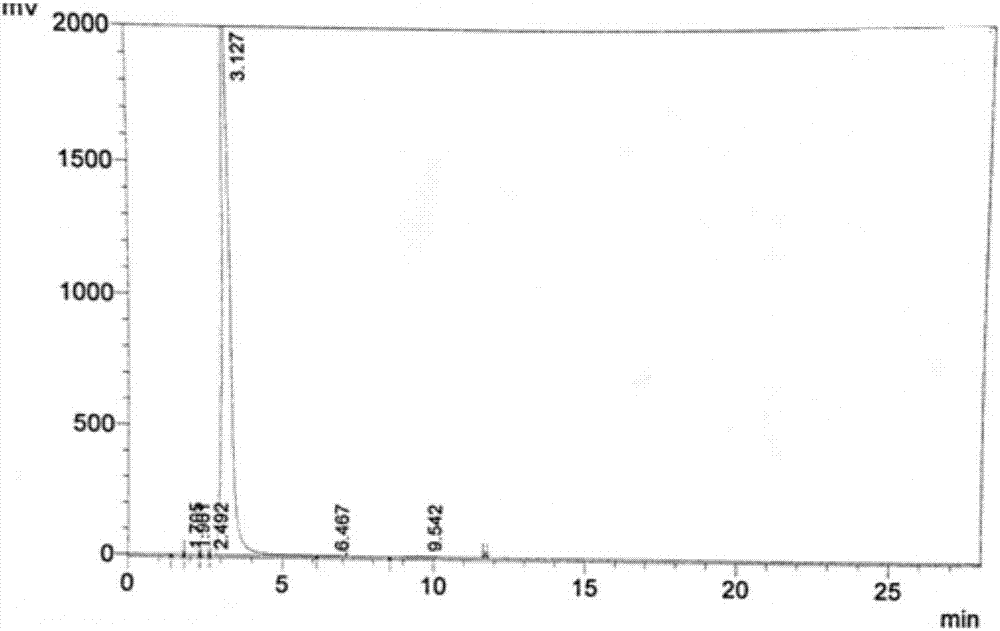

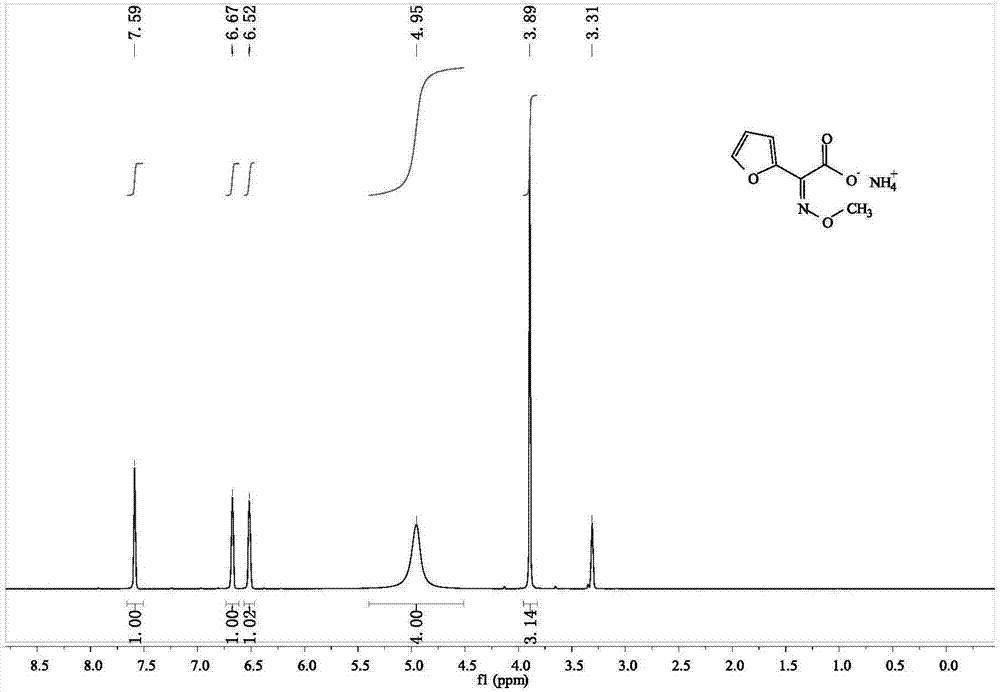

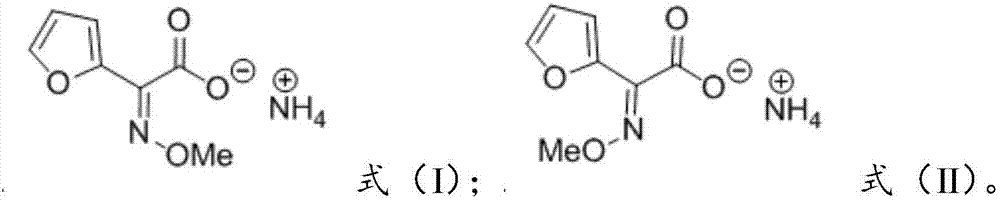

Method for recycling furan ammonium salt from furan ammonium salt waste liquid

The invention provides a method for recycling furan ammonium salt from furan ammonium salt waste liquid. The method comprises the following step: reacting by virtue of furan ammonium salt waste slag liquid in the presence of a solvent and a catalyst, wherein the catalyst is selected from one or more of metal chlorate, metal sulfate, metal nitrate, hydrogen phosphate salt, metal oxide, inorganic acid, organic acid and inorganic base, and metal is selected from one or more of sodium, potassium, calcium, magnesium, aluminum, zinc, iron and cobalt, and the reaction temperature is 50-150 DEG C. According to the method, (Z)-formula furan ammonium salt is directly converted from (E)-formula furan ammonium salt through a one-step method by utilizing the furan ammonium salt waste slag liquid at a specific temperature in a special catalyst system in the presence of the solvent, and finally a thermodynamically stable furan ammonium salt product is obtained. The method includes simple steps and is economic, environmentally friendly and suitable for industrial production, the recycling yield of furan ammonium salt is effectively increased, and meanwhile, the environmental protection pressure of the furan ammonium salt waste liquid is decreased.

Owner:四平市精细化学品有限公司 +1

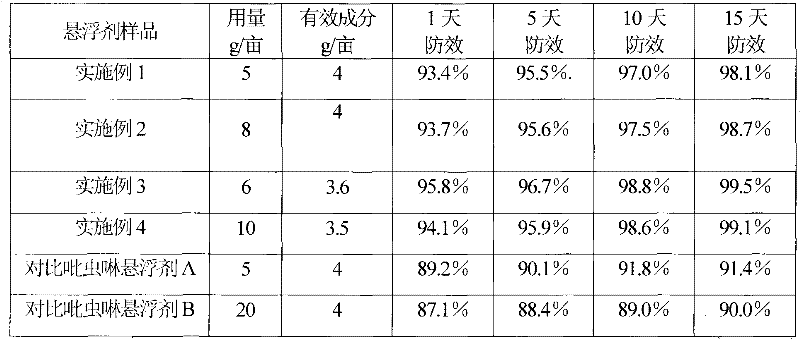

Imidacloprid suspension

The invention relates to an imidacloprid suspension, which is prepared from 1 to 80 weight parts of imidacloprid, 3 to 10 weight parts of dispersant or 5 to 30 parts of penetrating agent, 2 to 6 weight parts of antifreeze, 0.1 to 1.5 weight parts of thickener, 0.1 to 2.8 weight parts of defoaming agent and 5 to 90 weight parts of deionized water. The suspension has high suspension rate, more stable hot storage performance; and in field aphid prevention and control experiment, the dose of imidacloprid is low, and the pest killing effect is remarkable.

Owner:德强生物股份有限公司

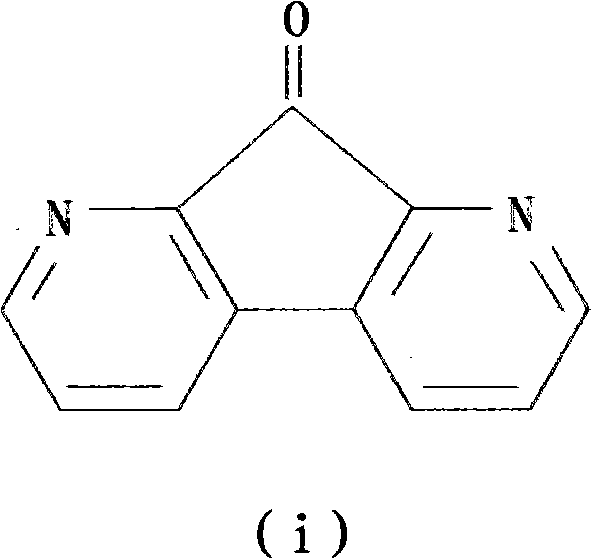

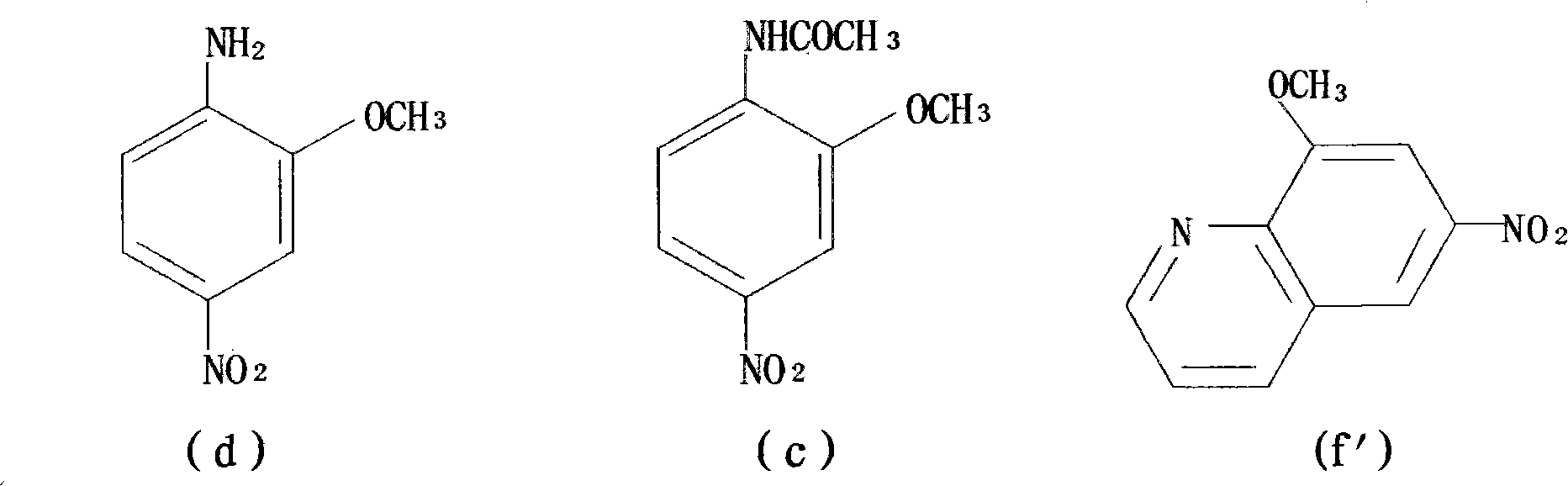

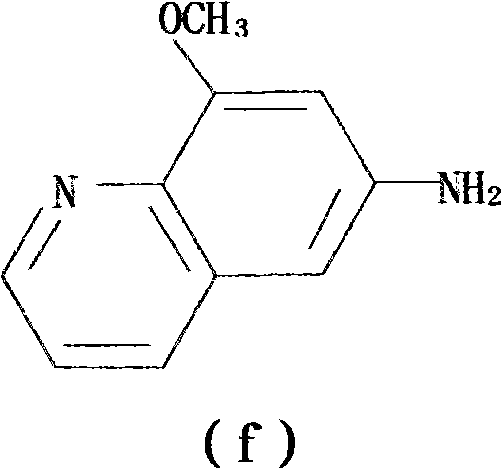

Preparation method of 1,8-dinitro-9-fluorenone

The invention discloses a preparation method of 1,8-dinitro-9-fluorenone (DFO). The preparation method of DFO comprises the following steps that 2-methoxy-4-nitroaniline is synthesized from 2-methoxyaniline; the 2-methoxy-4-nitroaniline is reduced into 2-methoxy-p-phenylenediamine sulfate; the 2-methoxy-p-phenylenediamine sulfate undergoes Skraup quinoline synthesis twice to produce 5(6)-methoxy-4,7-naphthisodiazine; the 5(6)-methoxy-4,7-naphthisodiazine undergoes an oxidation reaction to produce 4,7-naphthisodiazine-5,6-diketone; and the 4,7-naphthisodiazine-5,6-diketone is circulated in an alkaline aqueous solution to produce a product DFO, wherein an overall yield of the five DFO synthesis steps is 26.3%. The preparation method of DFO simplifies a preparation process and effectively reduces a production cost. Through the preparation method of DFO, DFO output can satisfy domestic demands on DFO.

Owner:SUZHOU BEC BIOLOGICAL TECH

Method for recycling waste liquor of ammonium hexanedioic acid and recycling system thereof

InactiveCN101219946BSimple processWorkmanship is effectiveOrganic compound preparationCarboxylic compound separation/purificationCapacitanceAdipic acid / Ammonium

The invention relates to a method and a system for treating and recovering adipic acid ammonium waste liquid and the recovering method comprises the following steps: A. filtering the solid impurities in the waste liquid; B. controlling the temperature of the filtered waste liquid and acidizing the filtered waste liquid; C. decreasing the temperature of the acidulated waste liquid and crystallizing the acidulated waste liquid; D. collecting adipic acid crystal after solid-liquid separation; E. washing to get adipic acid crystal and collecting the adipic acid crystal after solid-liquid separation. The recovering method and recovering system of the invention have the following advantages that the recovering method and recovering system of the invention are able to acquire a purified adipic acid with standard capacitance and able to be circularly used in the industries such as an electrolytic capacitor, etc. with a simple and efficient technique and obvious economical benefit and environment protection effect.

Owner:RUYUAN YAO AUTONOMOUS COUNTY DONGYANGGUANG FORMED FOIL CO LTD

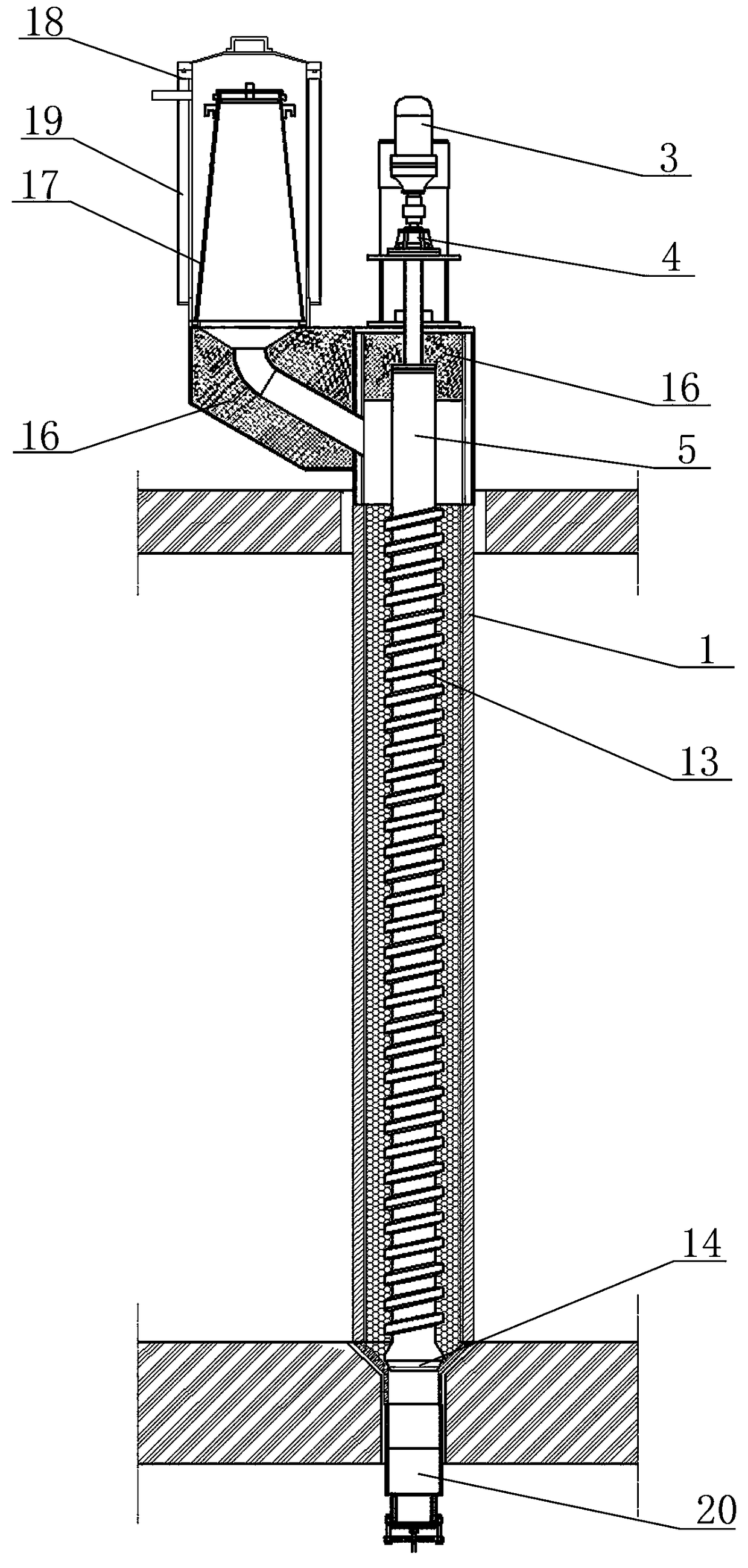

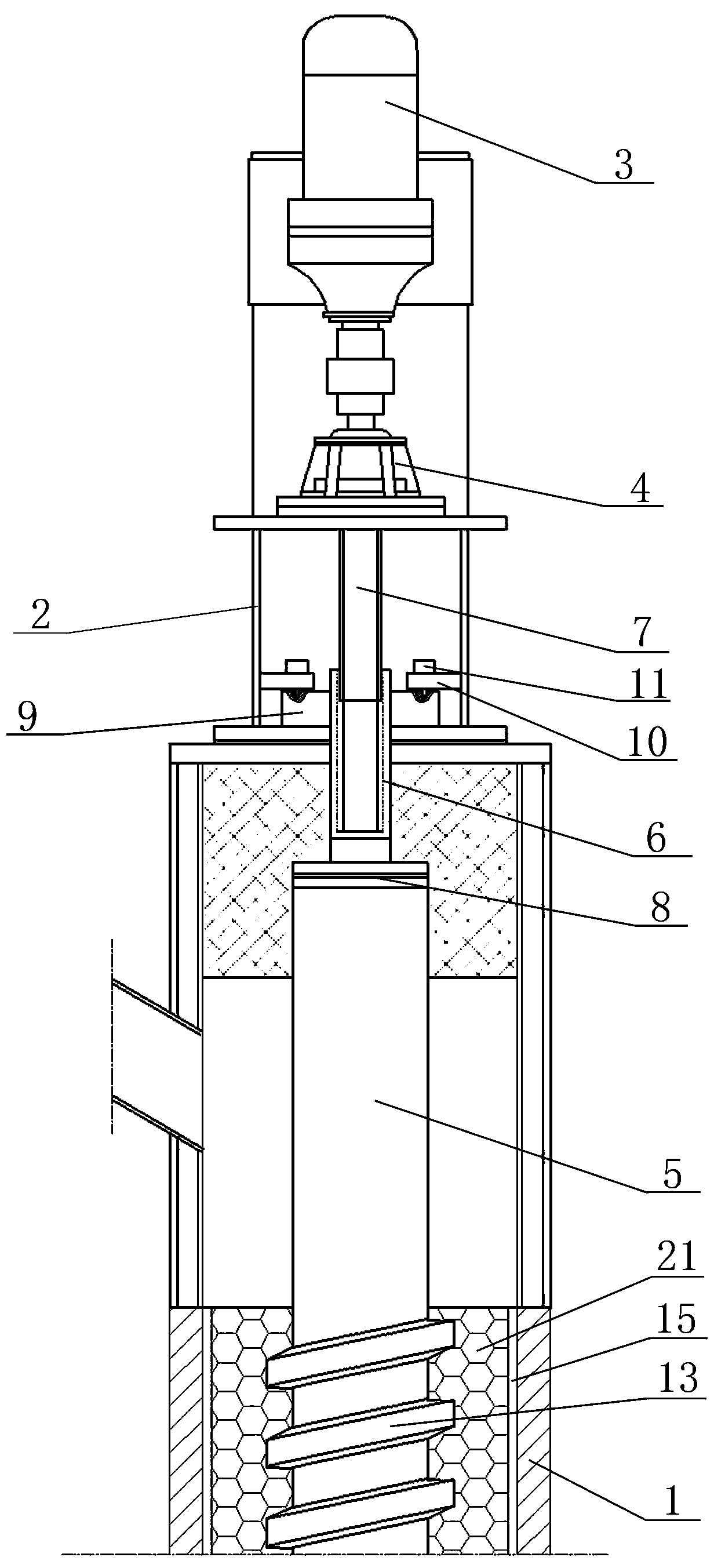

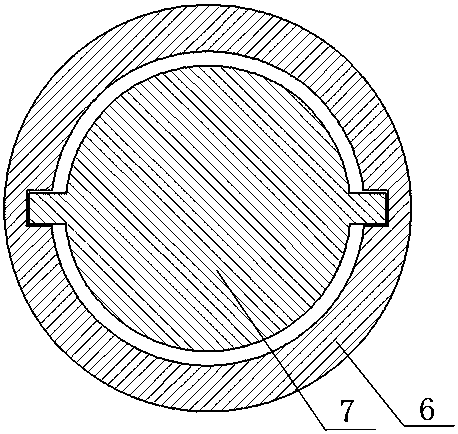

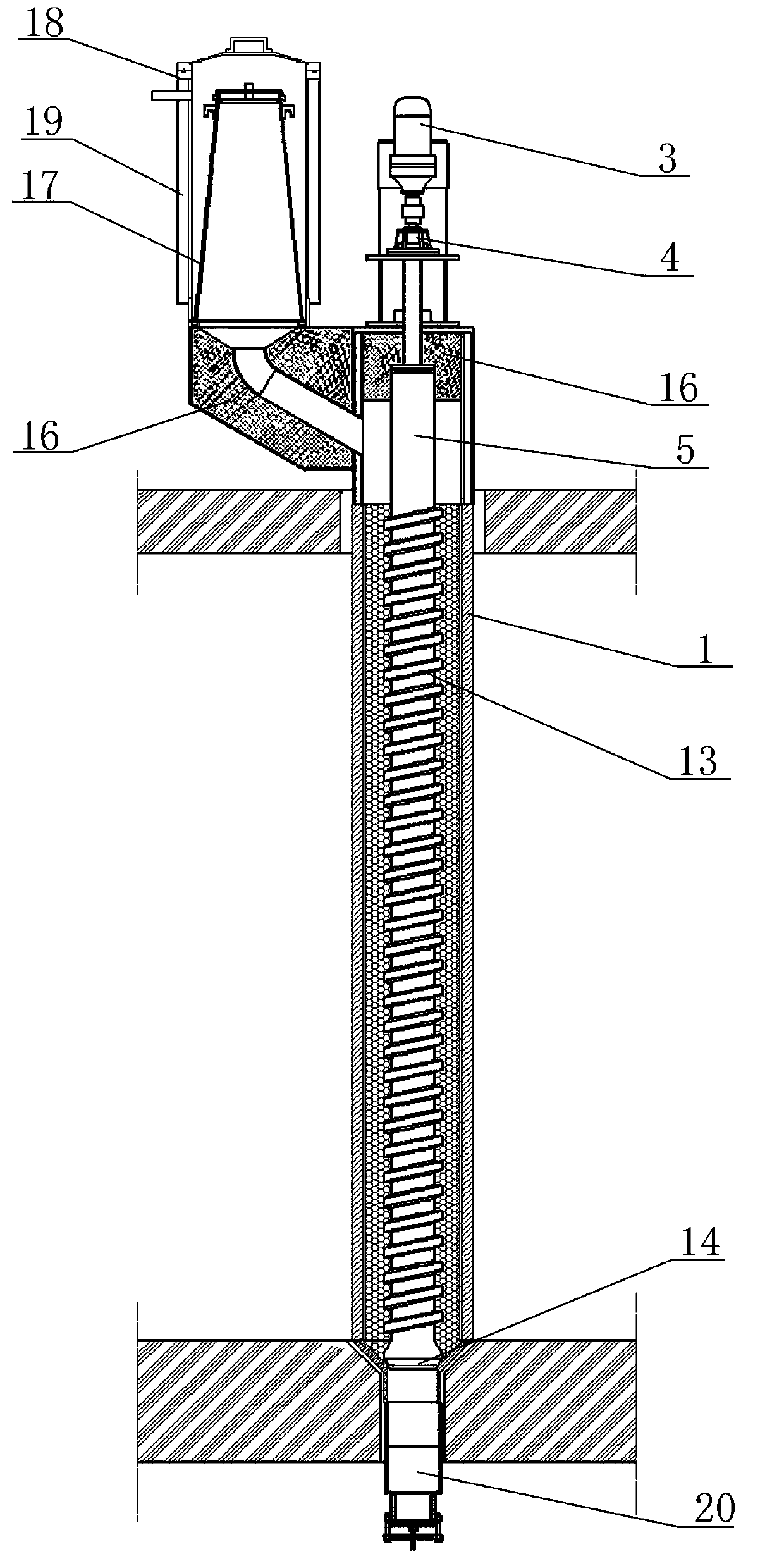

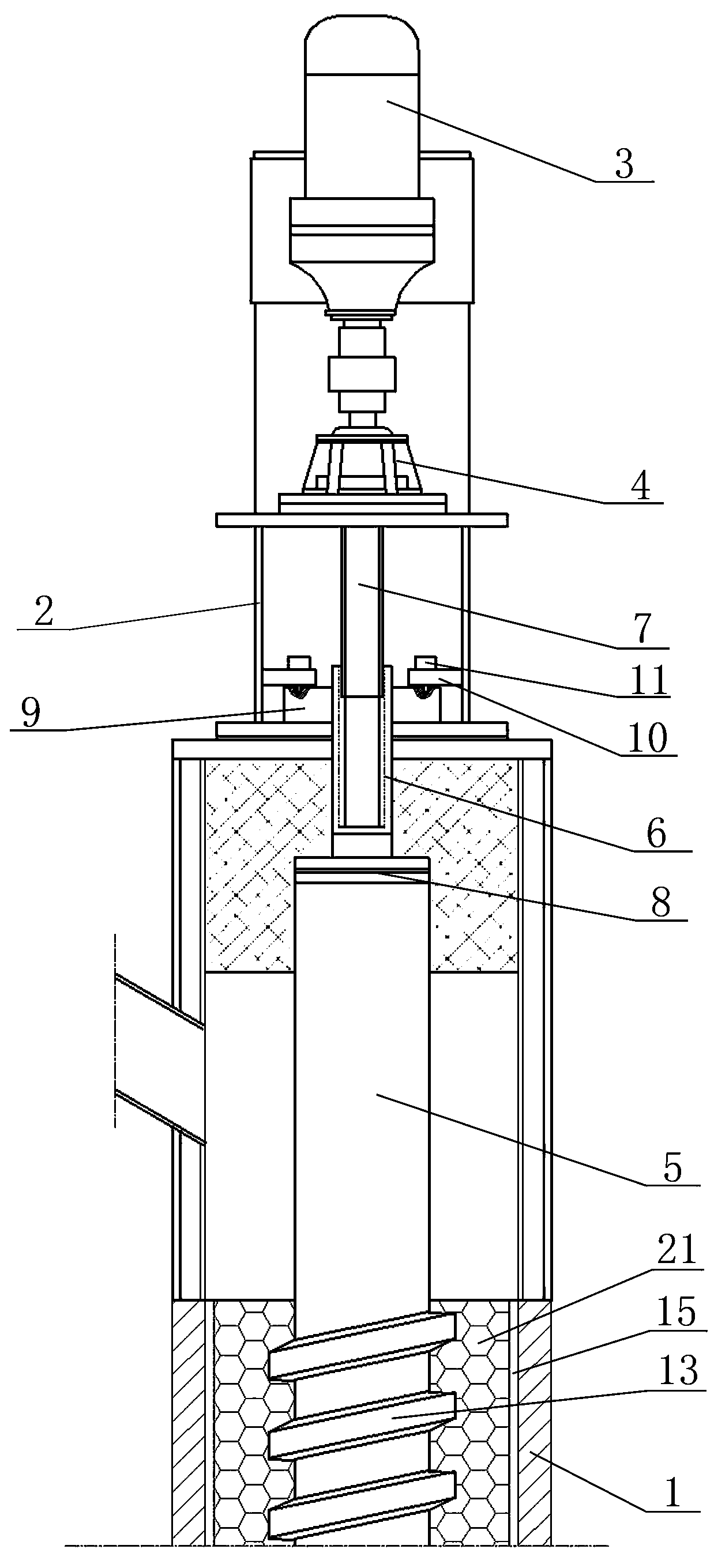

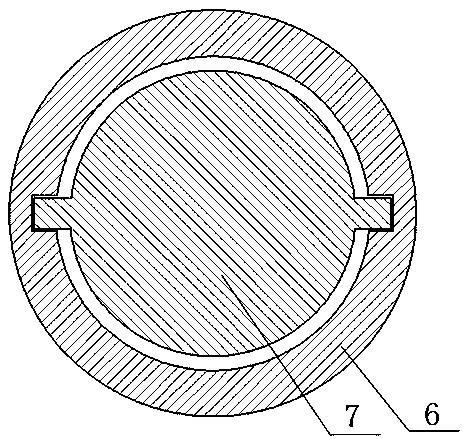

Reduction tank assembly with rotary stirring inner core structure for vertical reduction furnace

The invention discloses a reduction tank assembly with a rotary stirring inner core structure for a vertical reduction furnace. The reduction tank assembly comprises a vertical reduction tank body (1), wherein a mounting frame (2) is arranged at the outer upper end of the reduction tank body (1), a driving motor (3) and a speed reducer (4) are mounted on the mounting frame (2), an output shaft ofthe speed reducer (4) serves as a rotating inner shaft (7), the rotating inner shaft (7) is externally sleeved with a rotating outer shaft (6), the rotating outer shaft (6) stretches into the reduction tank body (1) and is connected with a rotating core shaft (5) through a coupler (8). The reduction tank assembly is reasonable to design and is particularly suitable for stirring materials in the reduction process of a metal magnesium vertical tank reduction furnace. The reduction tank assembly is also suitable for the stirring heating of materials in the reduction procedure of other metal vertical tanks, the heating uniformity of the whole materials can be realized according to the heating requirements, and the materials on an inner layer are effectively reduced, so that the reduction yieldis maximized, and meanwhile, the reduction time is greatly shortened.

Owner:西安银研镁业装备有限公司

Supporting construction for upper layer tanks of double row tank magnesium reducing furnace

InactiveCN101363686AResistance to lateral thrustExtended service lifeFurnace componentsMuffle furnacesBrickEngineering

The invention relates to a double-row tank magnesium reduction furnace in the field of non-ferrous metal metallurgy, in particular to a bearing structure of an upper tank of the double-row tank magnesium reduction furnace, which consists of upper tank supporting bricks and lower pedestal lattice bricks, wherein, the upper tank supporting bricks take a shape of saddle, while the lower pedestal lattice bricks are twin type connected by a base. The invention solves the problems of poor strength of bearing bricking-up structure of the upper tank, easy damage, largely shielding heating to the lower part of a reduction tank, uneven heating of materials in the tanks, small flowing section of smoke in the furnace, uneven temperature in the furnace, and the like.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Recycling method of retired lithium ion battery positive electrode materials

InactiveCN110760685AImprove the mixing effectGood dispersionWaste accumulators reclaimingProcess efficiency improvementElectrolytic agentElectrical battery

The invention discloses a recycling method of retired lithium ion battery positive electrode materials. The recycling method includes the following steps that firstly, retired lithium ion batteries are taken and subjected to discharging processing, shells are peeled off, the positive electrode materials of the lithium ion batteries are smashed after electrolyte in the batteries is washed away, andmixed powder is obtained; secondly, the mixed powder is placed in a periodic pulsating high-gradient magnetic separator, the magnetic separation field intensity is set to be larger than 1.0 T, and magnetic objects are separated out; thirdly, the magnetic separation field intensity is regulated to 1.2 T to 1.7 T, and second-time magnetic separation is conducted on the mixed powder; fourthly, the magnetic separation field intensity is regulated to 1.5 T to 1.7 T, and third-time magnetic separation is conducted on the mixed powder; and fifthly, a valve is opened, the magnetic field is turned offafter non-magnetic substance powder is discharged, the magnetic objects are discharged, and weak-magnetism ultrafine powder and non-magnetic powder are obtained. By means of the recycling method, theweak-magnetism powder in lithium battery smashed materials can be effectively recycled, and the recycling productivity is increased; and meanwhile, the recycling method is simple in process, low in cost, free of pollution, good in practicability and suitable for popularization

Owner:JIANGXI UNIV OF SCI & TECH

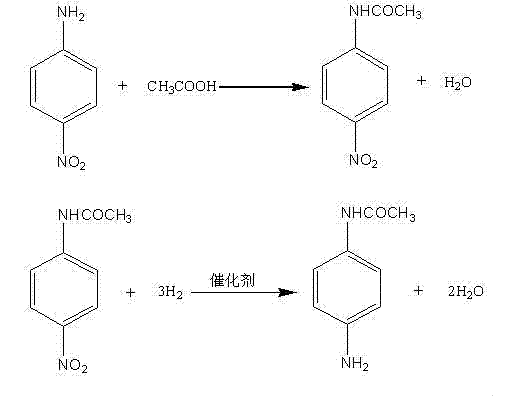

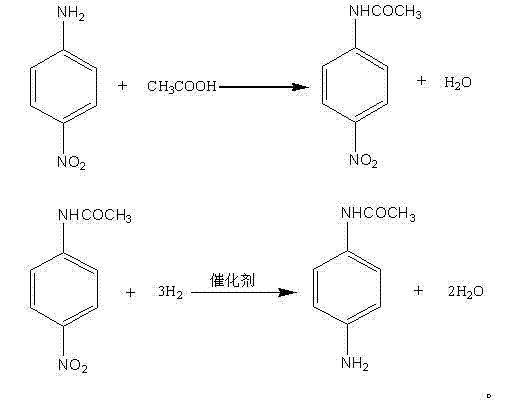

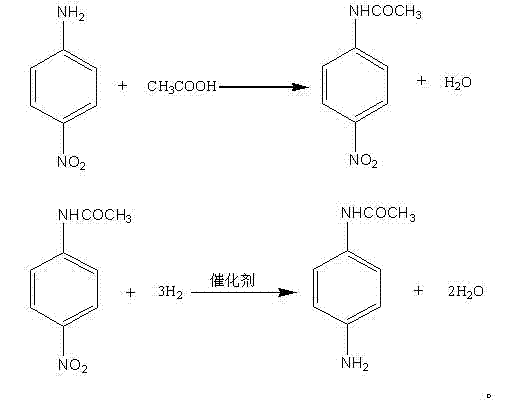

Preparation method of para aminoacet anilide

InactiveCN103787908AReduce pollutionHigh yieldOrganic compound preparationCarboxylic acid amides preparationAcetic acidReflux

The invention provides a preparation method of para aminoacet anilide. The preparation method comprises the following steps: (1) adding paranitroaniline and glacial acetic acid into a reaction kettle to obtain mixed liquor; (2) heating the mixed liquor obtained in the step (1), and carrying out a heat-preserved distilling reaction in a constant pressure reflux state to obtain reaction liquid; (3) after the reaction liquid obtained in the step (2) is fully dissolved and cooled, filtering, washing and drying to obtain paranitroacetanilide; (4) adding paranitroacetanilide, a catalyst and an organic solvent in a high pressure kettle, and respectively replacing by using nitrogen and hydrogen to obtain para aminoacet anilide solution; (5) filtering the para aminoacet anilide liquor obtained in the step (4) to obtain a para aminoacet anilide coarse product; and (6) adding the para aminoacet anilide coarse product in a solvent, heating for dissolving the para aminoacet anilide coarse product, then cooling, filtering and drying in vacuum to obtain the para aminoacet anilide prodcut. According to the method provided by the invention, existing methods of preparing para aminoacet anilide are changed and the effects of no environmental pollution, high yield and the like in production are achieved.

Owner:SHANDONG WUYANG CHEM

A method for recovering high-purity potassium chloride from fluorination reaction by-products

ActiveCN106006679BRegularity improvementImprove particle size distributionAlkali metal halide purificationPotassium fluoridePotassium

The invention provides a method for recovering highly pure potassium chloride from a fluorination reaction byproduct. The method comprises the following steps: 1, preprocessing: carrying out heat treatment on the fluorination reaction byproduct to remove adhered organic matter wastes; 2, dissolving and separating: placing a preprocessed solid mixture in a separation device, introducing liquid ammonia to dissolve potassium fluoride in the preprocessed solid mixture to form a mixed solution, filtering the mixed solution to obtain a filter cake which is crude primary potassium chloride and a filtrate which is a liquid ammonia solution of potassium chloride, squeezing the filtrate, introducing the squeezed filtrate to a pressure reducing chamber, and reducing the pressure to normal pressure to gasify the liquid ammonia in the filtrate in order to obtain a pure potassium fluoride solid; 3, washing: adding a mixed solvent A to the crude primary potassium chloride, washing the crude primary potassium chloride to remove residual trace impurities, and filtering the washed crude primary potassium chloride to obtain crude secondary potassium chloride; and 4, purifying: adding deionized water to the crude secondary potassium chloride, heating the deionized water to dissolve the crude secondary potassium chloride in order to prepare a saturated solution, cooling the saturated solution to room temperature, adding a solvent B to carry out re-crystallization, filtering the obtained solution, washing obtained crystals with the solvent b, and drying the washed crystals to obtain highly pure potassium chloride.

Owner:RONGCHENG QINGMU CHEM MATERIALS

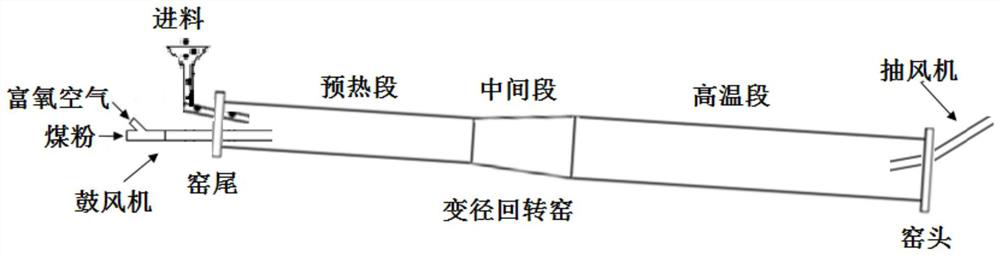

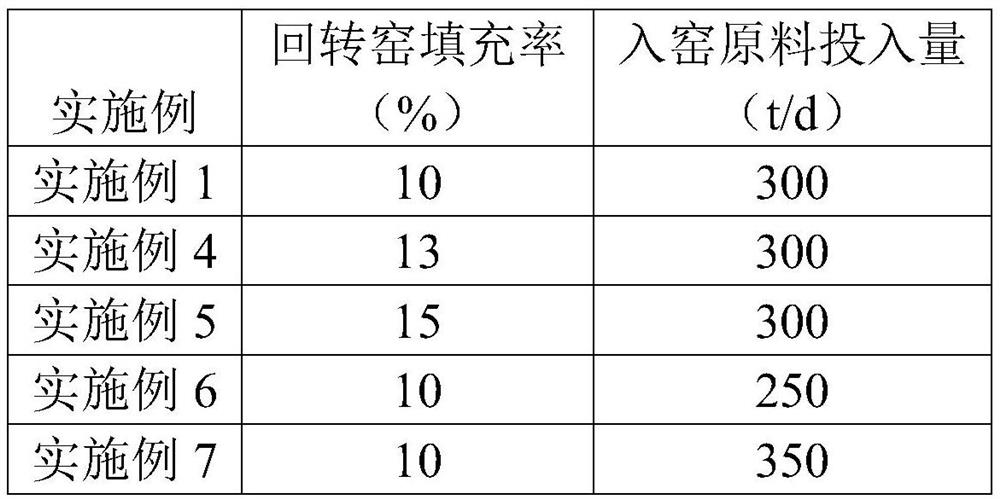

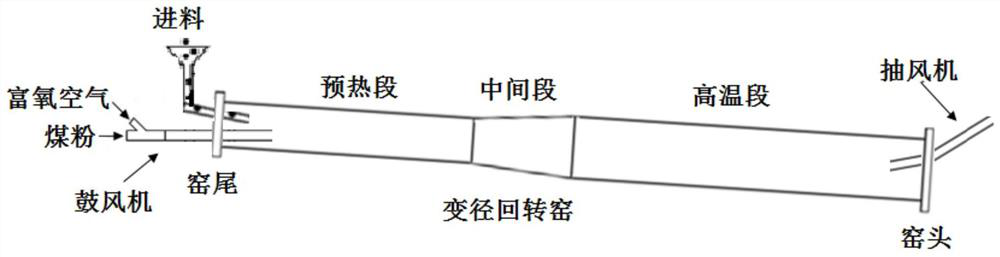

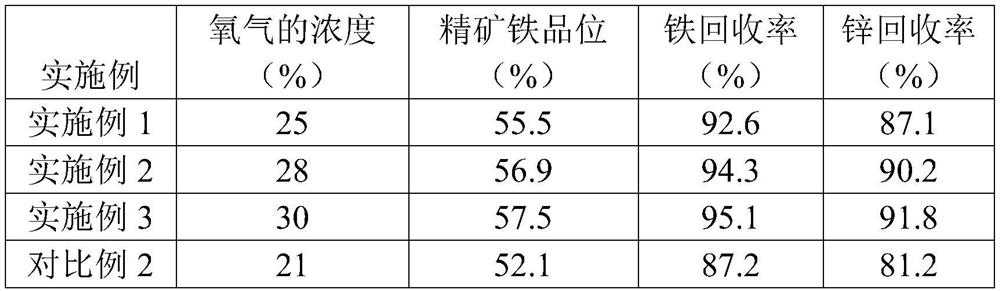

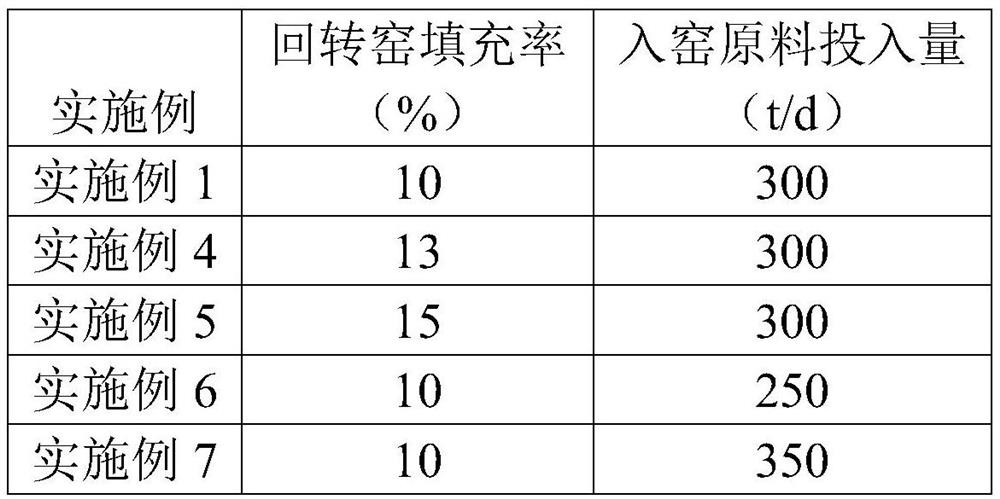

Method for performing zinc enrichment recovery through rotary kiln

ActiveCN111733330AAvoid loopsHigh recovery rateRotary drum furnacesProcess efficiency improvementPhysical chemistryProcess engineering

The invention provides a method for performing zinc enrichment recovery through a rotary kiln. A preheated input raw material is sent to a kiln tail of a diameter-variable rotary kiln, pulverized coaland oxygen-enriched air are blown into the kiln tail, and roasting reaction is executed for 80-100 minutes; under the action of a kiln head exhaust fan, a flowing direction of smoke generated by theroasting reaction keeps consistent with a moving direction of the input raw material, and the smoke and the raw material both move from the kiln tail to the kiln head; roasted ore is collected, and iron ore concentrate is obtained through ore grinding and magnetic separation; the smoke exhausted by the exhaust fan is collected and purified, a dust collection system is enabled to collect zinc-containing dust, the zinc-containing dust is mixed with the input raw material for pelleting, a mixed input raw material is obtained, the mixed input raw material is sent into the diameter-variable rotarykiln, a roasting working procedure and a zinc-containing dust collection working procedure are executed circularly, and thus, circular enrichment of the zinc is realized; after zinc content in the smoke reaches more than 10%, the zinc-containing dust in the smoke is directly collected, and zinc recovery is executed through an acid leaching technology. The method can effectively improve recovery rate of iron and zinc, prevent ring forming of the rotary kiln and be efficient and energy-saving.

Owner:UNIV OF SCI & TECH BEIJING

Cutting fluid used for grinding high-speed tool steel grinding wheel

InactiveCN102839042AEffective softeningEffective precipitationLubricant compositionVegetable oilAnoxomer

The invention relates to a cutting fluid used for grinding a high-speed tool steel grinding wheel. The cutting fluid comprises following components: 10-20% by weight of mineral oil, 5-10% by weight of animal and vegetable oil, 0.1-1% by weight of antioxygen, 2-5% by weight of an antiwear agent, 1-3% by weight of an antirust agent, 0.2-0.6% by weight of metal powder precipitator, and the balance water. The cutting fluid has good lubricating, cooling, antirust and cleaning effects; and meanwhile the metal powder precipitator is added in the formula to achieve effective softening and precipitating for metal powder, control and collection of the metal powder are convenient, and the recovery yield of the metal powder is greatly improved.

Owner:JURONG HENGXIANG TEXTILE

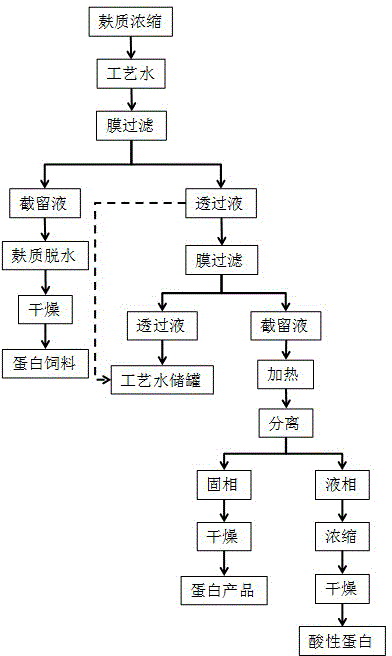

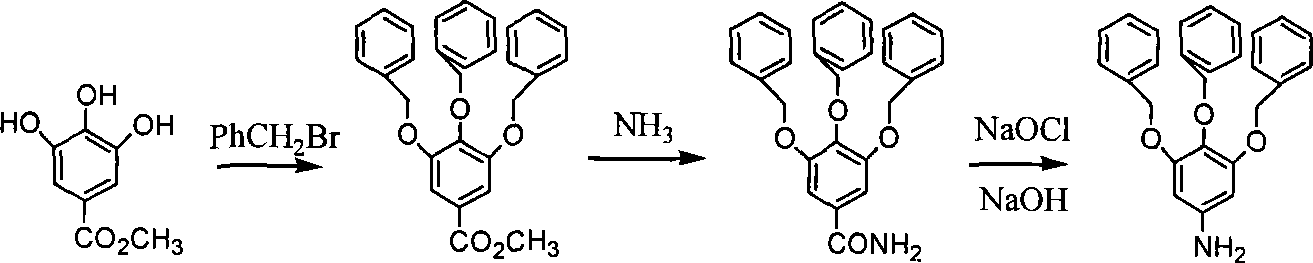

Corn starch process water protein recovery technique

ActiveCN104672299ALittle impact on utilizationGood dispersionPeptide preparation methodsEngineeringCorn starch

The invention provides a corn starch process water protein recovery technique which comprises the following steps: 1) treating process water, which is generated in the gluten concentration step in a wet-grinding technique for producing corn starch, to obtain a first permeation solution and a first trapped fluid containing rich com gluten meal; 2) filtering the first permeation solution through a hyperfiltration membrane with the molecular weight cut-off of 10-200 kDa under the conditions of 3-4 Bar and 35-45 DEG C to obtain a second permeation solution and a second trapped fluid containing rich soluble proteins; and 3) heating the second trapped fluid at 75-150 DEG C for 0.3 second-31 minutes, coagulating to precipitate a first protein product, separating to obtain a first protein product and a separation liquid, and concentrating and drying the separation liquid to obtain a second protein product. The recovery technique overcomes the defect that the traditional technique only treats the insoluble com gluten meal in the process water generated by the gluten concentration step, can obtain the two protein products, and can enhance the yield of the com gluten meal.

Owner:COFCO NUTRITION & HEALTH RES INST +1

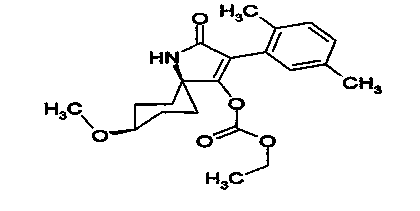

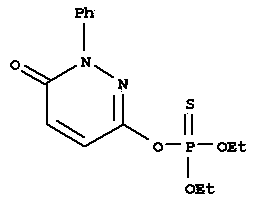

Pesticide insecticidal composition containing spirotetramat and pyridaphenthion

ActiveCN103478150AFree from pestsHigh insecticidal activityBiocideNematocidesAdditive ingredientPyridaphenthion

The invention relates to a pesticide insecticidal composition containing spirotetramat and pyridaphenthion, and the insecticidal composition is highly effective for controlling harmful organisms. The pesticide insecticidal composition containing the spirotetramat and the pyridaphenthion contains the active ingredients, namely the spirotetramat and the pyridaphenthion, wherein the weight ratio of the spirotetramat to the pyridaphenthion is 50: 1-1: 50. The active compound combination disclosed by the invention has special systemic property, namely by using the insecticidal composition disclosed by the invention to perform treatment on seeds, the seeds can be protected, and plants obtained after germination can be further protected from being damaged by pests. Therefore, the immediate treatment of crops during seeding or slightly after seeding can be avoided; compared with various independent active compounds, the active compound combination disclosed by the invention has synergistically increased insecticidal activity; the insecticidal activity exceeds the sum of activities of two active compounds during respective application, so that the optimization of the quantity of the used active compounds becomes possible.

Owner:JIANGSU ROTAM CHEM

Reduction tank assembly with rotating stirring inner core structure for vertical reduction furnace

The invention discloses a reduction tank assembly with a rotary stirring inner core structure for a vertical reduction furnace. The reduction tank assembly comprises a vertical reduction tank body (1), wherein a mounting frame (2) is arranged at the outer upper end of the reduction tank body (1), a driving motor (3) and a speed reducer (4) are mounted on the mounting frame (2), an output shaft ofthe speed reducer (4) serves as a rotating inner shaft (7), the rotating inner shaft (7) is externally sleeved with a rotating outer shaft (6), the rotating outer shaft (6) stretches into the reduction tank body (1) and is connected with a rotating core shaft (5) through a coupler (8). The reduction tank assembly is reasonable to design and is particularly suitable for stirring materials in the reduction process of a metal magnesium vertical tank reduction furnace. The reduction tank assembly is also suitable for the stirring heating of materials in the reduction procedure of other metal vertical tanks, the heating uniformity of the whole materials can be realized according to the heating requirements, and the materials on an inner layer are effectively reduced, so that the reduction yieldis maximized, and meanwhile, the reduction time is greatly shortened.

Owner:西安银研镁业装备有限公司

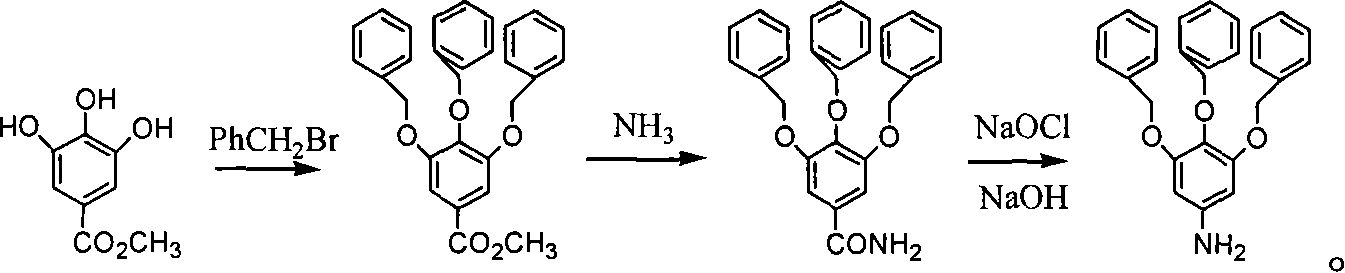

Chemical synthesis of 3,4,5-trioxyaniline

InactiveCN101029008ALow priceLow costOrganic compound preparationAmino-hyroxy compound preparationChemical synthesisIce water

A process for chemically synthesizing 3,4,5-tribenzyloxy phenylamine includes such steps as reaction between 3,4,5-methyl trihydroxybenzoate and benzylbromin in inertial organic solvent, adding the resultant to ice water, filtering, depositing, baking, recrystallizing in the mixture of ethyl acetate and petroether to obtain 3,4,5-methyl tribenzyloxybenzoate, dissolving it in ethanediol solution, filling ammonia gas, cooling to educe out needle solid, filtering, washing to obtain 3,4,5-tribenzyloxy benzoylamine, dissolving it in methanol, adding sodium hypochlorite solution and sodium hydroxide, reaction to obtain 3,4,5-tribenzyloxy phenylamino formate, adding sodium hydroxide, hydrolysis, cooling, filtering washing and baking.

Owner:XIAMEN UNIV

A kind of water protein recovery process of corn starch process

ActiveCN104672299BLittle impact on utilizationGood dispersionPeptide preparation methodsEngineeringCorn starch

The invention provides a corn starch process water protein recovery technique which comprises the following steps: 1) treating process water, which is generated in the gluten concentration step in a wet-grinding technique for producing corn starch, to obtain a first permeation solution and a first trapped fluid containing rich com gluten meal; 2) filtering the first permeation solution through a hyperfiltration membrane with the molecular weight cut-off of 10-200 kDa under the conditions of 3-4 Bar and 35-45 DEG C to obtain a second permeation solution and a second trapped fluid containing rich soluble proteins; and 3) heating the second trapped fluid at 75-150 DEG C for 0.3 second-31 minutes, coagulating to precipitate a first protein product, separating to obtain a first protein product and a separation liquid, and concentrating and drying the separation liquid to obtain a second protein product. The recovery technique overcomes the defect that the traditional technique only treats the insoluble com gluten meal in the process water generated by the gluten concentration step, can obtain the two protein products, and can enhance the yield of the com gluten meal.

Owner:COFCO NUTRITION & HEALTH RES INST +1

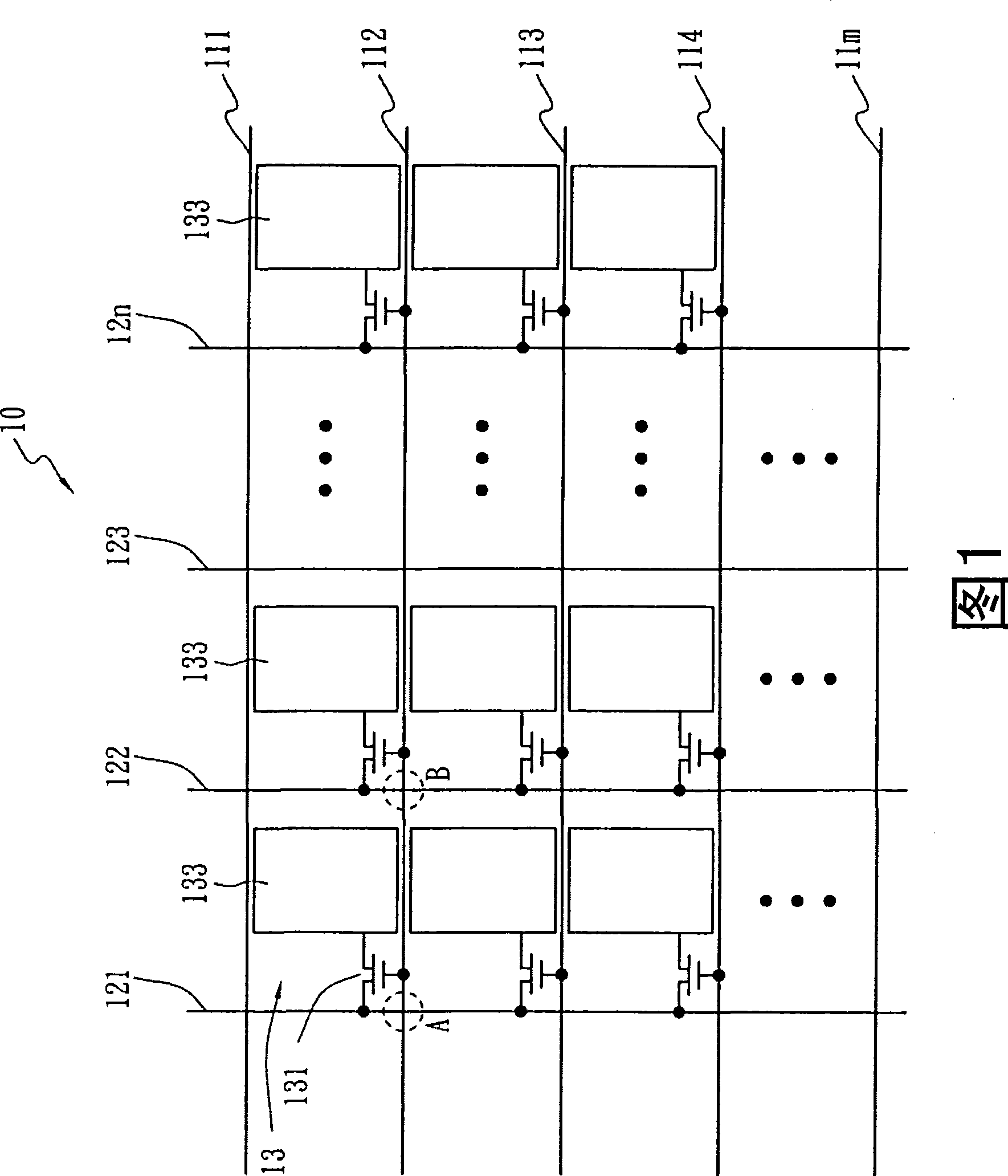

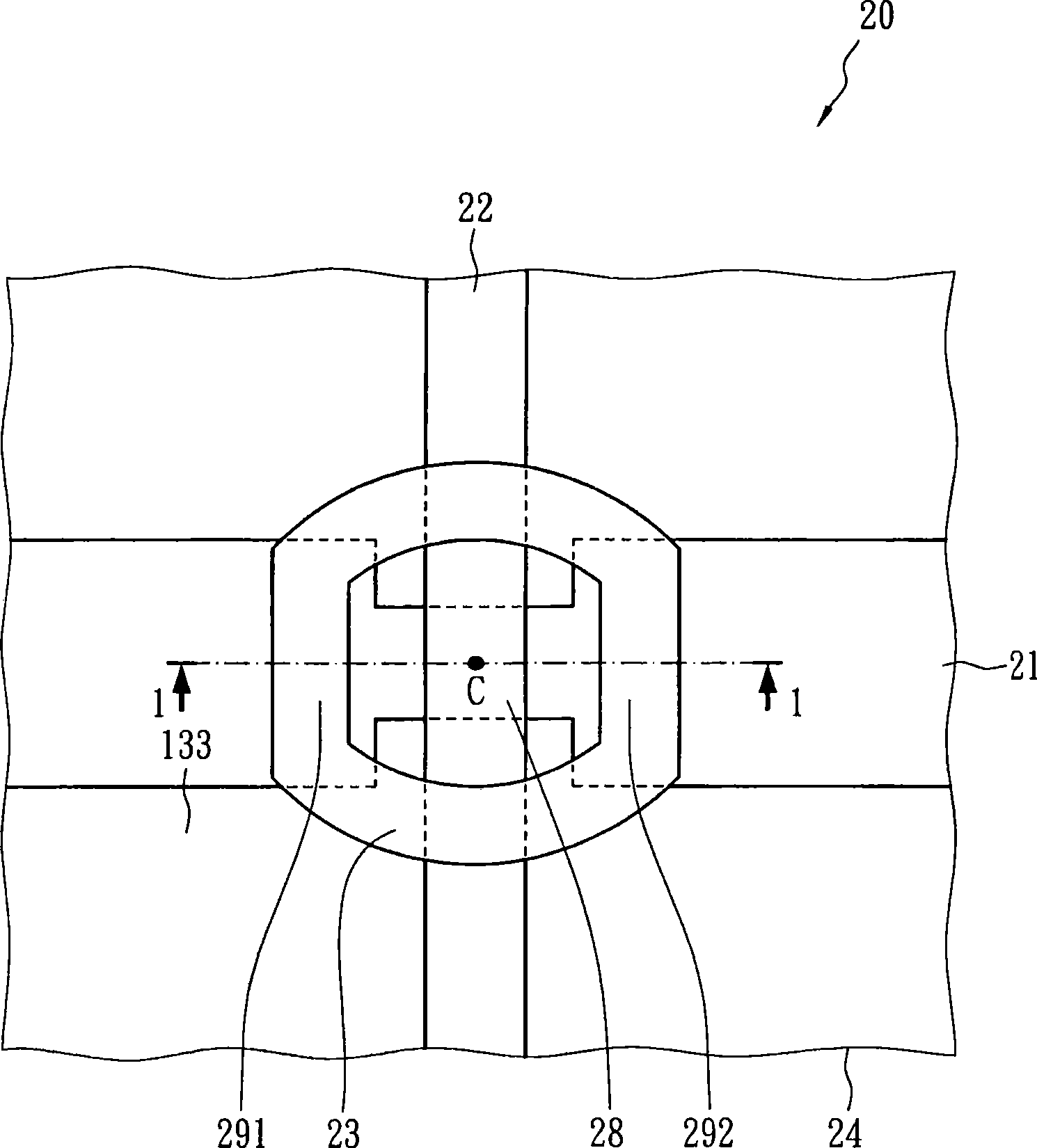

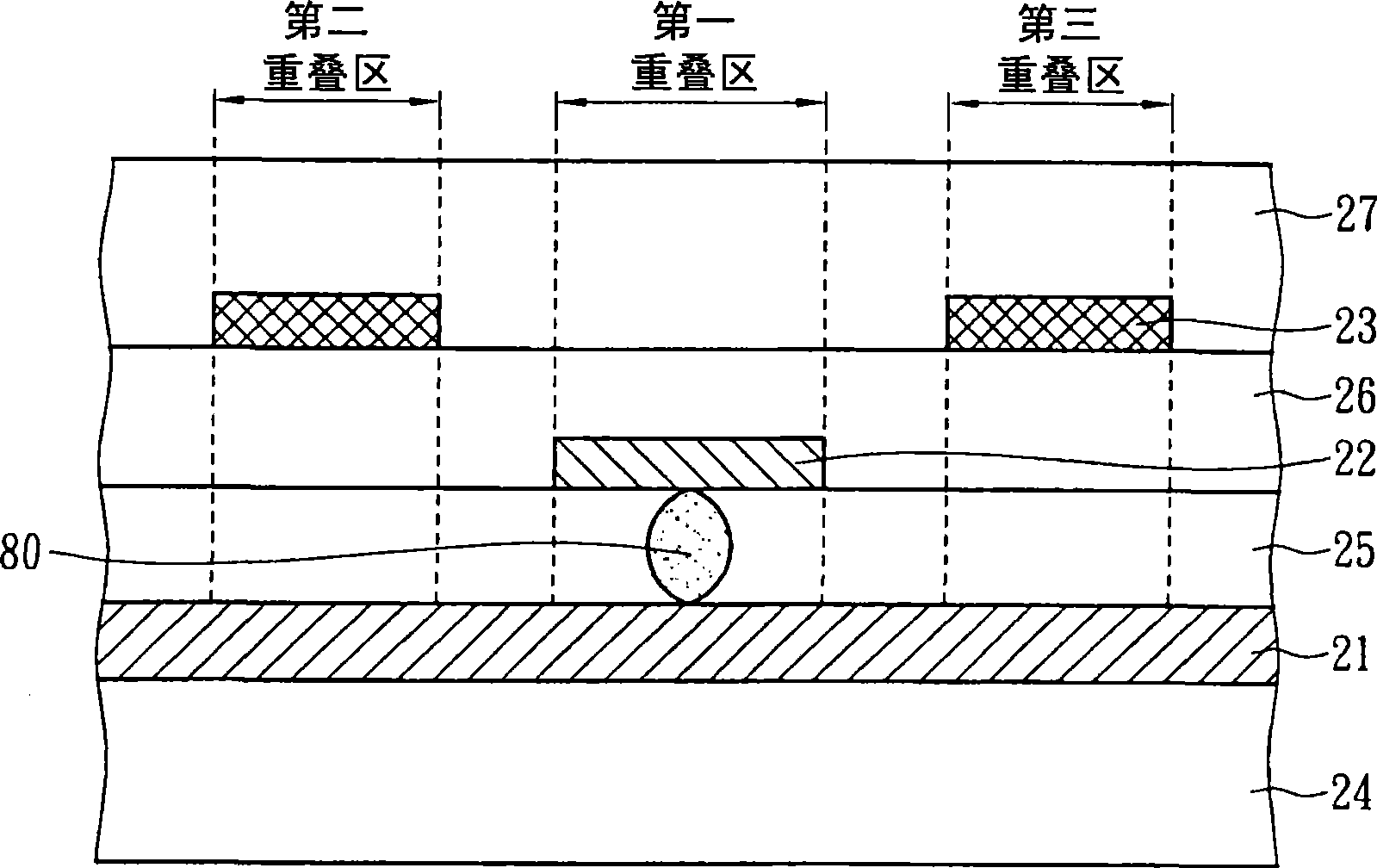

Display apparatus and repairing method therefor

InactiveCN101452908AImprove recovery yieldShorten the timeSemiconductor/solid-state device detailsSolid-state devicesDisplay deviceBiomedical engineering

Owner:HANNSTAR DISPLAY CORPORATION

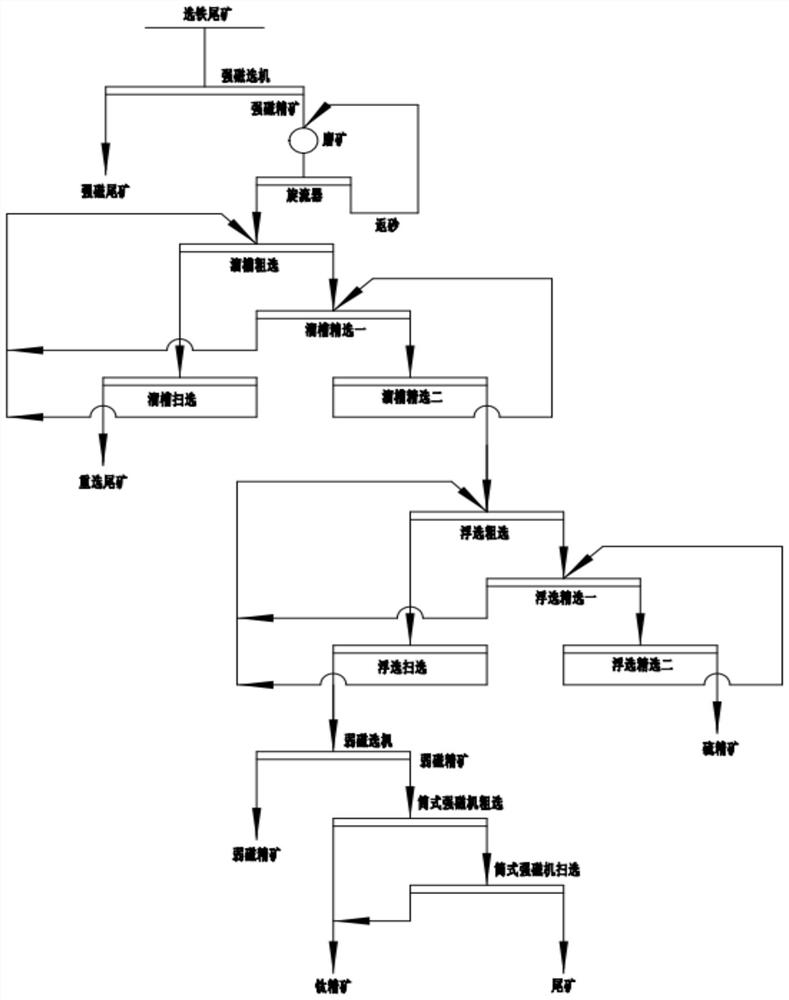

Method for recovering ilmenite from iron separation tailings

ActiveCN112871438AImprove recovery, yieldIncrease outputHigh gradient magnetic separatorsFlotationOre concentrateTitanium

The invention discloses a method for recovering ilmenite from iron separation tailings. The method comprises the following steps that S1, strong-magnetic tailing discarding is carried out on the iron separation tailings to obtain strong magnetic concentrate and strong magnetic tailings; S2, the obtained strong magnetic concentrate is subjected to closed-circuit ore grinding; S3, the raw materials obtained through ore grinding are reselected to obtain reselected concentrate and reselected tailings; S4, the obtained reselected concentrate is subjected to flotation desulfurization treatment to obtain flotation concentrate and sulfur concentrate; S5, the obtained flotation concentrate is subjected to iron removal to obtain magnetite concentrate and weak magnetic concentrate; and S6, the weak magnetic concentrate is subjected to roughing and scavenging to obtain titanium concentrate. The method can improve the grade of the titanium concentrate, improve the recovery rate of the titanium concentrate, improve the resource utilization rate and reduce environmental pollution.

Owner:攀枝花青杠坪矿业有限公司 +1

A kind of multi-component master alloy for aluminum alloy and preparation method thereof

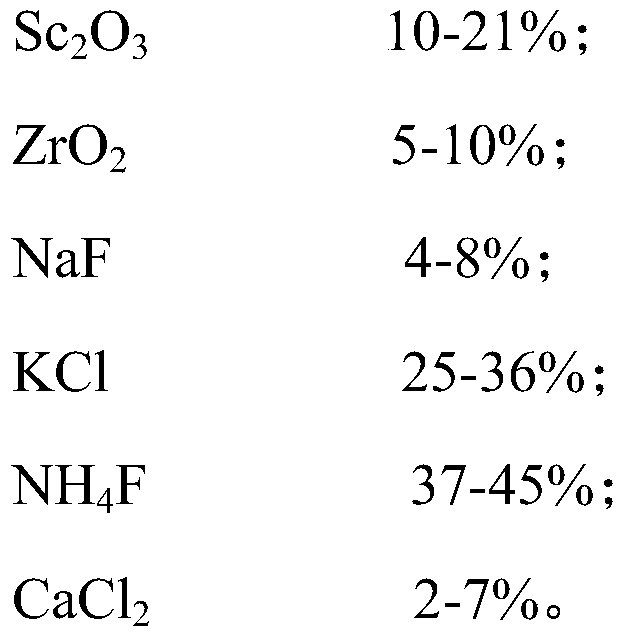

The invention discloses a multi-element intermediate alloy for an aluminum alloy and a preparing method of the multi-element intermediate alloy. The multi-element intermediate alloy comprises, by mass, 2%-6% of Mg, 0.2%-0.8% of Mn, 0.08%-0.8% of Sc, 0.08%-0.4% of Zr and the balance Al. a fused salt aluminothermic reducing method is adopted for alloy preparation. By means of the multi-element intermediate alloy and the preparing method, the content of scandium and zirconium in the intermediate alloy is greatly reduced, the reducing yield of the scandium and zirconium is improved, and the production cost of a scandium and zirconium contained alloy is reduced; and meanwhile, magnesium and manganese are used in an assisted manner for strengthening, and the multi-element intermediate alloy is good in comprehensive performance and has the very good intensified metamorphism effect.

Owner:HUNAN ORIENTAL SCANDIUM

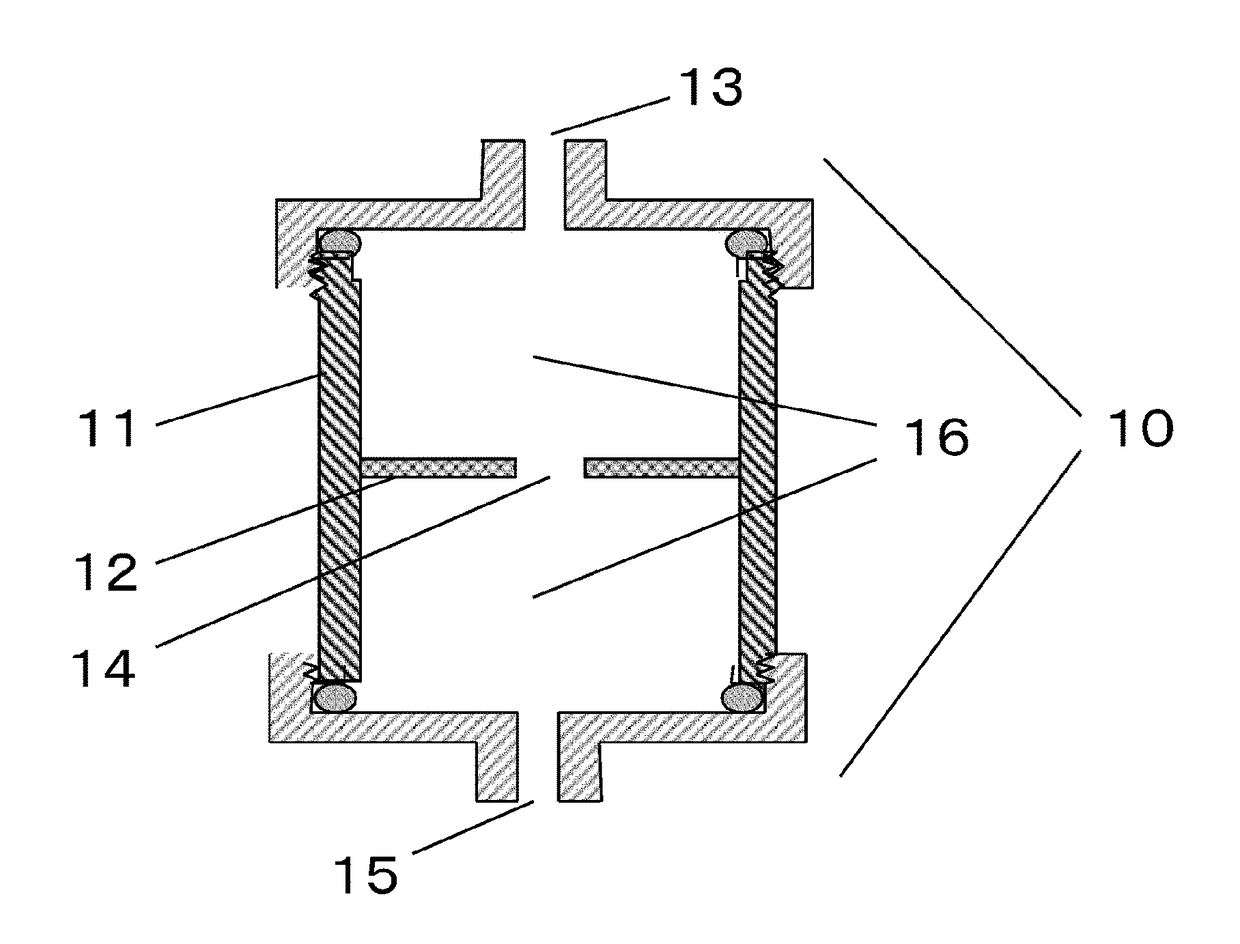

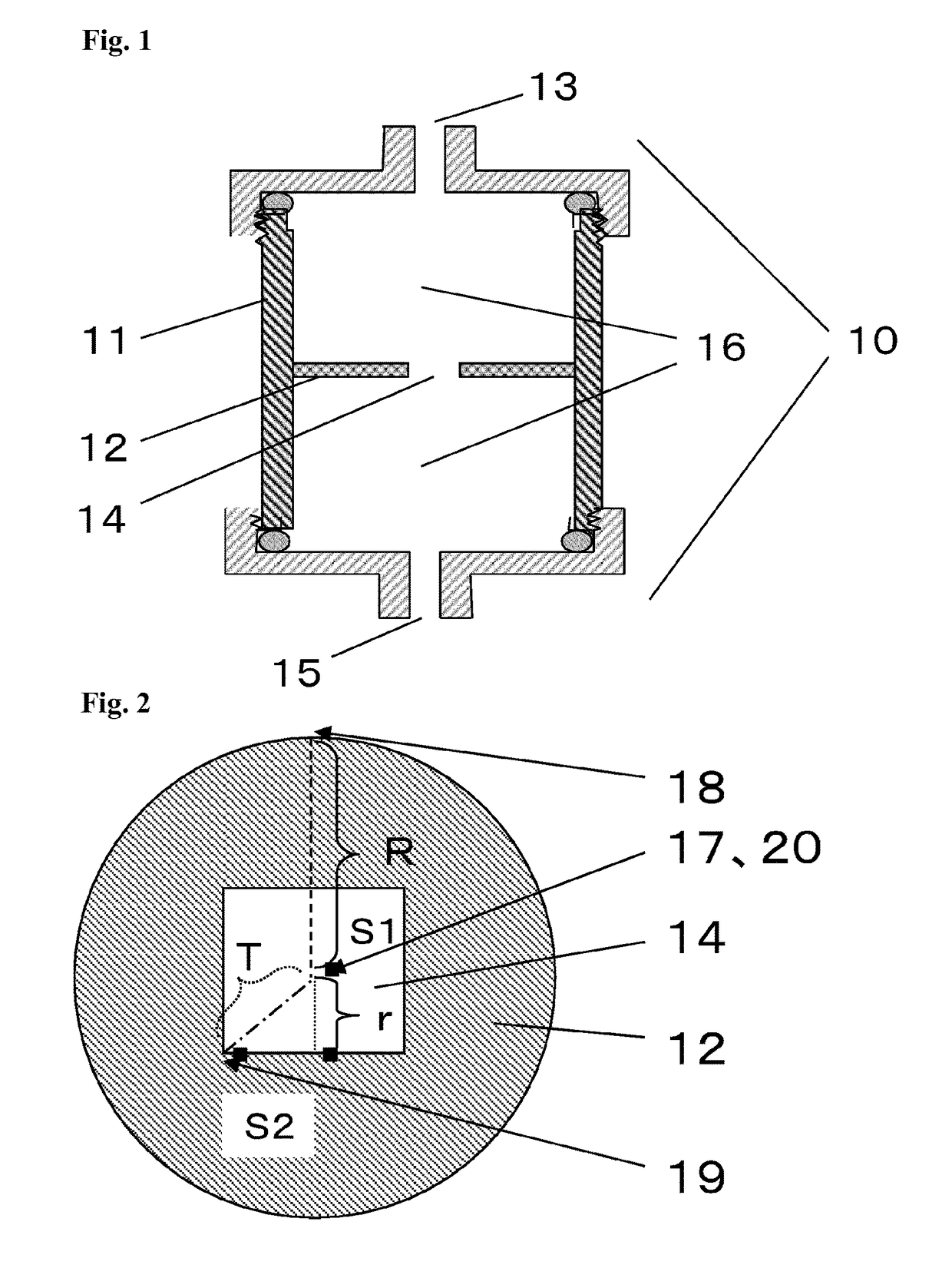

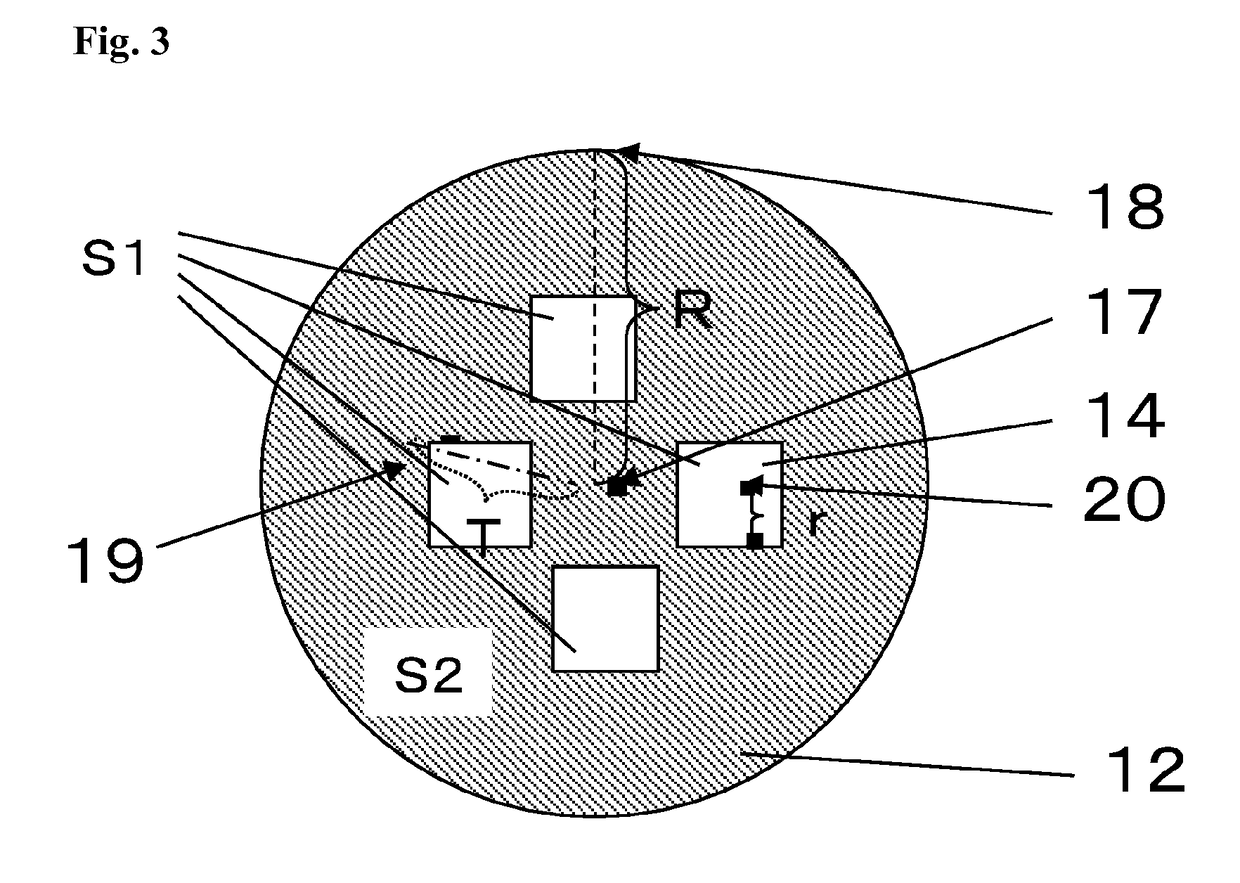

Nucleated-cell capturing filter and nucleated-cell preparation method using same

ActiveUS9746453B2Reduce flow rateIncrease contact timeHaemofiltrationBlood/immune system cellsNonwoven fabricCell isolation

Owner:KANEKA CORP

Method for Enrichment and Recovery of Zinc Using Rotary Kiln

ActiveCN111733330BAvoid loopsHigh recovery rateRotary drum furnacesProcess efficiency improvementThermodynamicsFlue gas

The invention provides a method for enriching and recovering zinc by using a rotary kiln. Send the preheated kiln raw materials into the kiln tail of the variable diameter rotary kiln, and blow coal powder and oxygen-enriched air into the kiln tail to carry out the calcination reaction for 80-100 minutes; The flow direction of the gas is consistent with the movement direction of the raw materials entering the kiln, and they all move from the kiln tail to the kiln head; collect roasted ore, grind ore and magnetically separate to obtain iron concentrate; the flue gas extracted by the exhaust fan is Collection and purification treatment, use the dust collection system to collect zinc-containing dust, mix and granulate it with the kiln raw materials, and obtain the mixed kiln materials, send them to the variable-diameter rotary kiln, and cycle through the calcination process and the zinc-containing dust collection process to achieve Circular enrichment of zinc; when the zinc content in the flue gas reaches more than 10%, directly collect the zinc-containing dust in the flue gas, and use the acid leaching process to recover zinc. The method can effectively improve the recovery rate of iron and zinc, prevent the ring formation of the rotary kiln, and has high efficiency and energy saving.

Owner:UNIV OF SCI & TECH BEIJING

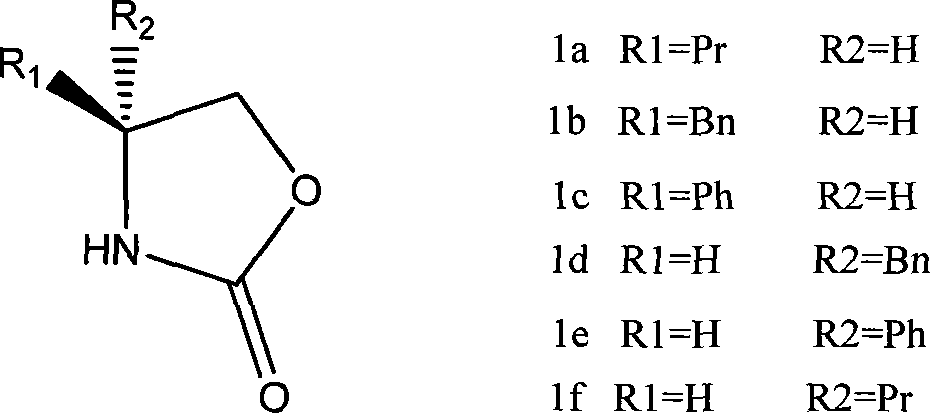

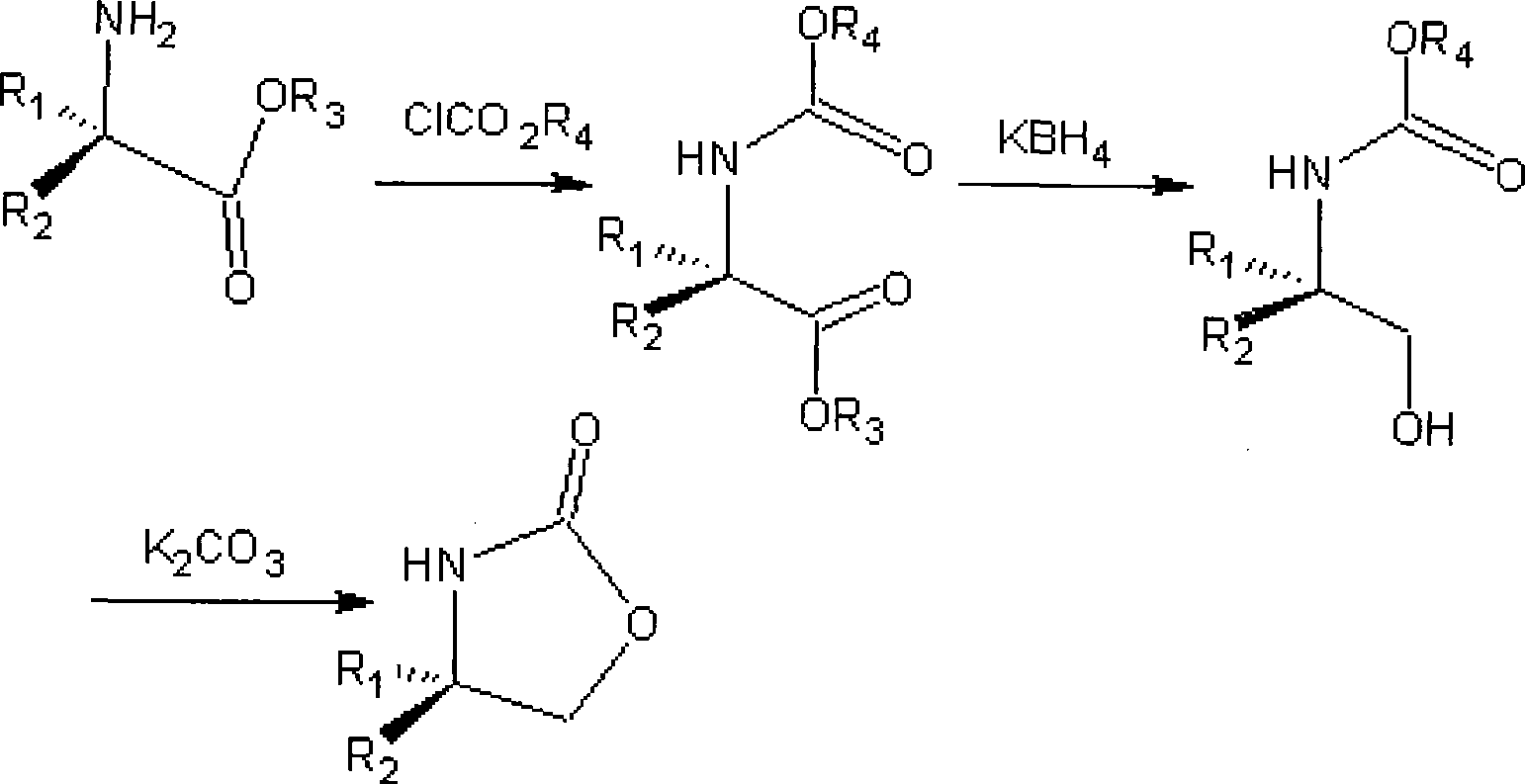

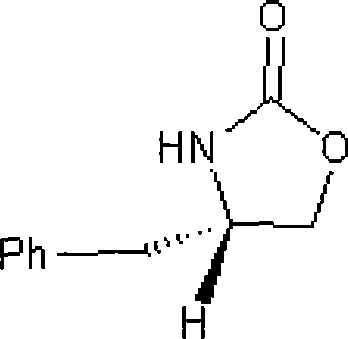

Method for preparing 4-substituted chirality oxazolidinone compounds

The invention relates to a preparation method of chiral 4-substituted oxazolidone, which belongs to the pharmaceutical chemistry technical field. Chiral amino acid ester or chiral amino acid ester salt is added into a solvent, supercarbonate is charged, chloro formate is titrated at the room temperature, and mixed for 5 to 8 hours at the room temperature after titration is completed, filtering isperformed, and the solvent is recovered to obtain an intermediate compound a; the intermediate compound a is adopted in an anhydrous chloride solution for accelerating the catalyst of borohydride, reaction is performed for 4 to 10 hours at 0 to 40 DEG C, the solvent is recovered, a citric acid solution is added, extraction is performed by using ethyl acetate, an organic layer is combined, the solvent is recovered, and then an intermediate compound b is obtained; potassium carbonate is added into the intermediate compund b, heating, back flow and water diversion are performed for 2 to 4 hours,pump filtering is performed before cooling down, the filter liquor is cooled and recrystallized, pump filtering and drying are then performed to obtain a white crystalline solid 4-substituted chiral oxazolidone chemical compound. The invention provides the preparation method of a 4-substituted chiral oxazolidone chemical compound, the invention aims at the problem of significant safe hidden danger caused when phosgene is adopted for acidylation and cyclization in the prior art.

Owner:SUQIAN KEYLAB BIOCHEMICAL CO LTD

Method for recovery and utilization of dodecanedioic acid purification and crystallization mother liquor

ActiveCN104447280BGood colorEasy to purifyOrganic compound preparationHydroxy compound preparationTotal nitrogenDicarboxylic acid

The invention provides a recycling method of mother liquor purifying, refining and crystallizing mother liquor of dodecanedioic acid, and belongs to the separation treatment method of non-acyclic dicarboxylic acid containing 12 carbon atoms. The recycling method comprises the steps of (1) recovering a solvent which is methanol; (2) distilling to dissolve and dilute materials residual at the bottom of a kettle; (3) performing acidification under a high temperature, and crystallizing; (4) drying. The recycling method of mother liquor purifying, refining and crystallizing mother liquor of dodecanedioic acid has the advantages that the recovered dodecanedioic acid product has a good color and luster and is of high purity, and moreover, the recovery yield is raised, the device investment is saved, the operation is simple and convenient, the resource can be saved, and the environment is protected; the recovery yield of the dodecanedioic acid product is not less than 97.0%; the product quality meets the technical indexes that the total acid is not less than 99.7wt% (percentage by weight), single acid is not less than 99.3wt%, ash content is not greater than 0.003wt%, the total nitrogen is not greater than 0.004wt%, ferric oxide is not greater than 0.0002wt%, and water content is not greater than 0.17wt%.

Owner:山东广通新材料有限公司

Preparation method of p-aminoacetanilide

PendingCN110734386AReduce pollutionImprove recovery yieldOrganic compound preparationCarboxylic acid amides preparationNitroacetanilidePhysical chemistry

The invention relates to a preparation method of p-aminoacetanilide, and the method comprises the following steps: (1) adding p-nitroacetanilide, zinc powder, ammonium chloride and water into a reaction kettle, uniformly mixing, heating, and keeping the temperature; (2), cooling, crystallizing and filtering the solution obtained in the step 1; (3) completely dissolving in the solution obtained inthe step (2), cooling, recrystallizing with ethanol, and filtering to obtain a p-aminoacetanilide solution; (4) filtering the p-aminoacetanilide solution obtained in the step (3) at 65-75 DEG C, distilling, cooling, and then filtering to obtain a p-aminoacetanilide crude product; (6) heating and dissolving the p-aminoacetanilide crude product; cooling, filtering and drying in vacuum to obtain a p-aminoacetanilide product, wherein the temperature of the p-nitroacetanilide, the zinc powder, the ammonium chloride and the water added into the reaction kettle is 95-100 DEG C, the heating and heat preservation time in the step (1) is 0.5-1.5 hours, the yield in the step (1) is 95%, the zinc powder and the ammonium chloride are used as reducing agents, the water is used as a solvent to reduce thep-nitroacetanilide, and the p-aminoacetanilide is synthesized.

Owner:新乡市锦源化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com