Method for Enrichment and Recovery of Zinc Using Rotary Kiln

A rotary kiln and enrichment technology, applied in the direction of rotary drum furnace, process efficiency improvement, furnace, etc., can solve the problems of low zinc oxide content in zinc-containing dust, low metallization rate of materials, and low production capacity of rotary kiln, etc. Achieve the effect of improving heat energy utilization rate, improving recovery rate and reducing sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The raw material is low-grade iron ore, and the method of zinc enrichment and recovery using a rotary kiln:

[0054] S1. Raw material preparation: use anthracite and coke powder with a mass ratio of 1:1 as reduced coal, mix them with iron ore and metallurgical dust to evenly pelletize and dry them, and obtain kiln raw materials with an average particle size distribution of 5-15mm; among them, The ratio of the reduced coal, the iron ore and the metallurgical dust is 25%: 35%: 40%; the ash content in the reduced coal is 8%, and the reflow temperature of the ash is greater than 1300°C .

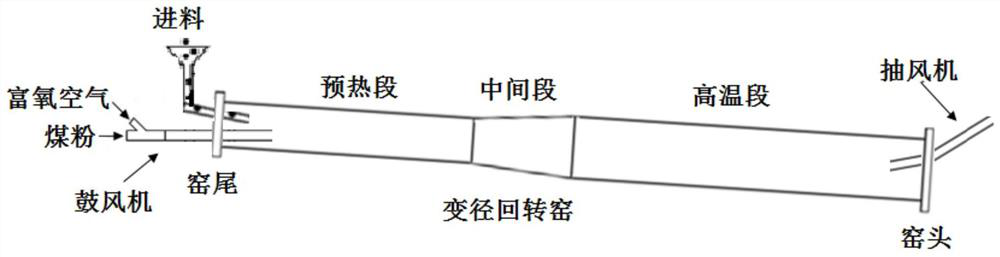

[0055] S2. Calcination process: preheat the kiln-entry raw material prepared in step S1 to 200°C, and then send it into the kiln tail of the variable-diameter rotary kiln. The filling rate of the variable-diameter rotary kiln is 10%; the input amount of the kiln raw material It is 300t / d; and at the end of the kiln, with a blower pressure of 150KPa, pulverized coal and oxygen-enriched ai...

Embodiment 2-3

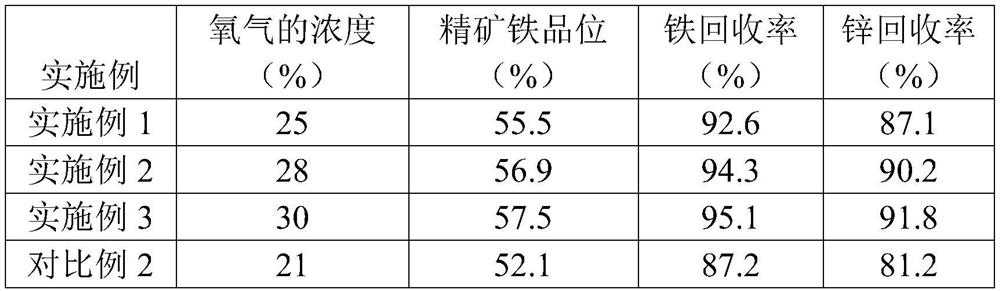

[0067] The difference from Example 1 lies in that the concentration of oxygen in the oxygen-enriched air is set differently, and other steps are the same as those in Example 1, which will not be repeated here.

[0068]

[0069] The present invention adopts oxygen-enriched air to carry out combustion-supporting, compared with the conventional air in comparative example 2 (oxygen concentration is 21%), can reduce combustion-supporting gas blowing amount, and then make flue gas emission greatly reduce, soot product (coarse zinc oxide ) grade has been improved. At the same time, due to the increase of oxygen concentration, the combustion rate is also improved, which can enhance the processing capacity of rotary kiln reduction roasting, make the recovery of iron ore sufficient, the recovery grade and recovery rate are improved, and the consumption of fuel is greatly reduced .

Embodiment 4-7

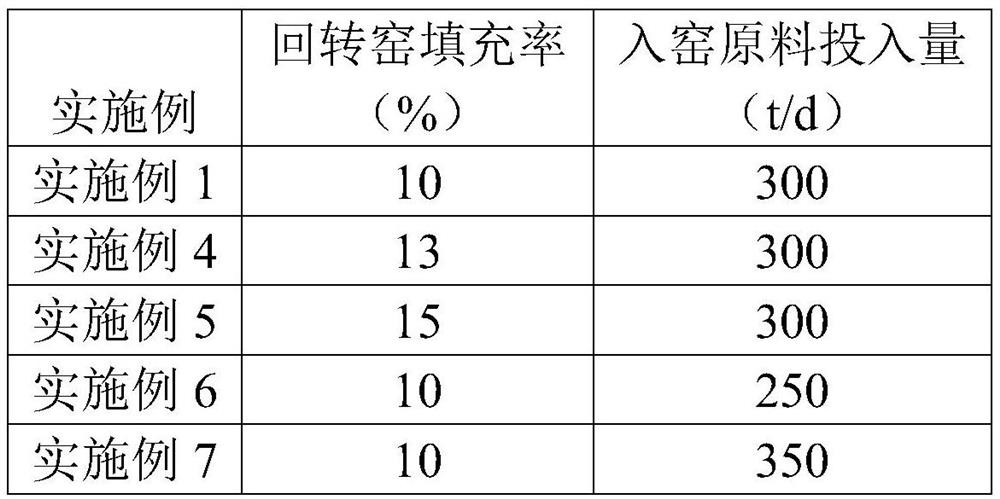

[0071] The difference from Example 1 is that the filling rate of the rotary kiln and the input amount of raw materials into the kiln are set differently, and the other steps are the same as in Example 1, and will not be repeated here.

[0072]

[0073] When the residence time of the material is constant, the increase of the filling rate of the rotary kiln and the input of raw materials into the kiln can increase the output of the rotary kiln, but due to the thickening of the material layer, the movement of the material is restricted, so it is unfavorable for the turning and roasting of the material. If the filling rate and input amount are too small, the production capacity of the equipment will not be effectively utilized, and the production cost will also be increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com