A kind of multi-component master alloy for aluminum alloy and preparation method thereof

An intermediate alloy and multi-component technology, applied in the field of aluminum alloys, can solve the problems of increasing the input amount of scandium oxide, uneven zirconium composition, and increasing production costs, and achieves good metamorphic strengthening effect, uniform distribution, and reduced content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

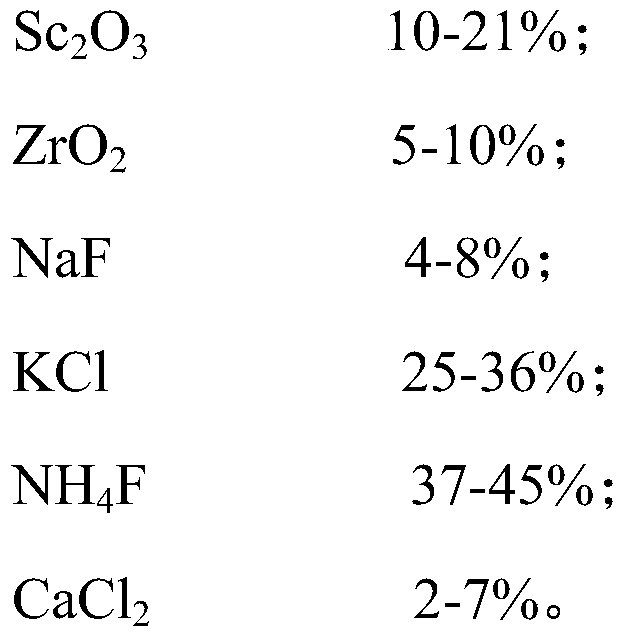

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: In a 200kg intermediate frequency electric furnace, 95kg of aluminum is put into a graphite crucible, and 5.17kg of molten salt (wherein: Sc 2 o 3 1.07kg, ZrO 2 0.4kg, NH 4 F 2.0kg, NaF 0.25kg, KCl 1.3kg, MgCl 2 0.15kg). Heat to 950°C and keep warm for 40 minutes. Stir and remove slag, then lower the temperature to 760°C, add 0.4kg of manganese and 5.6kg of magnesium, and stir evenly. After 10 minutes, charge Ar / N 2 Degassing, sample analysis, cooling to 710°C, water-cooled mold ingot, about 100kg ingot, composition analysis of ingot, Mg4.9%, Mn0.4%, Sc0.71%, Zr0.3%, balance Al.

Embodiment 2

[0025] Embodiment 2: In a 200kg intermediate frequency electric furnace, 100kg of Al is put into a graphite crucible, and 6.0kg of molten salt (wherein: Sc 2 o 3 1.2kg, ZrO 2 0.5kg, NH 4 F 2.3kg, NaF 0.3kg, KCl 1.5kg, MgCl 2 0.2kg). Heat to 900°C and keep warm for 1hr. Stir evenly, remove slag, then lower the temperature to 740°C, add 0.6 kg of manganese metal and 5.5 kg of metal magnesium, and stir evenly. After 15 minutes, charge Ar / N 2 Degassing, sample analysis, cooling to 720°C, water-cooled mold ingot, about 106kg ingot, ingot composition analysis: Mg5.0%, Mn 0.56%, Sc 0.75%, Zr 0.35%, balance Al.

Embodiment 3

[0026] Embodiment 3: In a 200kg intermediate frequency electric furnace, 100kg of Al is put into a graphite crucible, and 3.0kg of molten salt (wherein: Sc 2 o 3 0.6kg, ZrO 2 0.25kg, NH 4 F 1.15kg, NaF 0.15kg, KCl 0.75kg, MgCl 2 0.1kg). Heat to 900°C and keep warm for 1hr. Stir evenly, remove slag, then lower the temperature to 740°C, add 0.21kg of metal manganese and 2.5kg of metal magnesium, and stir evenly. After 15 minutes, charge Ar / N 2 Degassing, sample analysis, cooling to 720°C, water-cooled mold ingot, about 102kg ingot, ingot composition analysis: Mg2.2%, Mn 0.2%, Sc 0.37%, Zr 0.17%, balance Al.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com