Wooden core assembling molding press

A molding machine and a technology for forming blanks, which are used in wood compression, wood processing appliances, manufacturing tools, etc., can solve the problem that the geometric shape and dimensional accuracy of the finished glulam are difficult to guarantee, and the core of the blanks cannot be well locked and shaped, and the pressure device Unable to apply pressure evenly and effectively, to achieve the effect of effective automatic control and management, deformation correction, and balance of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

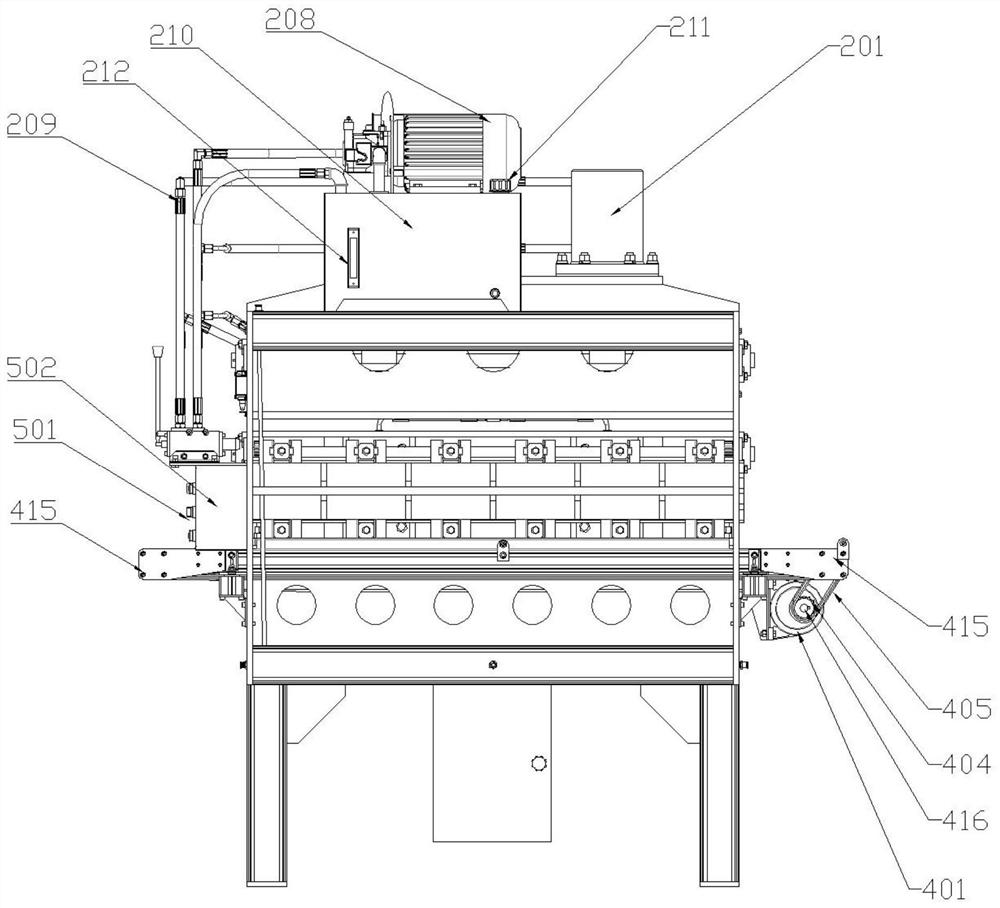

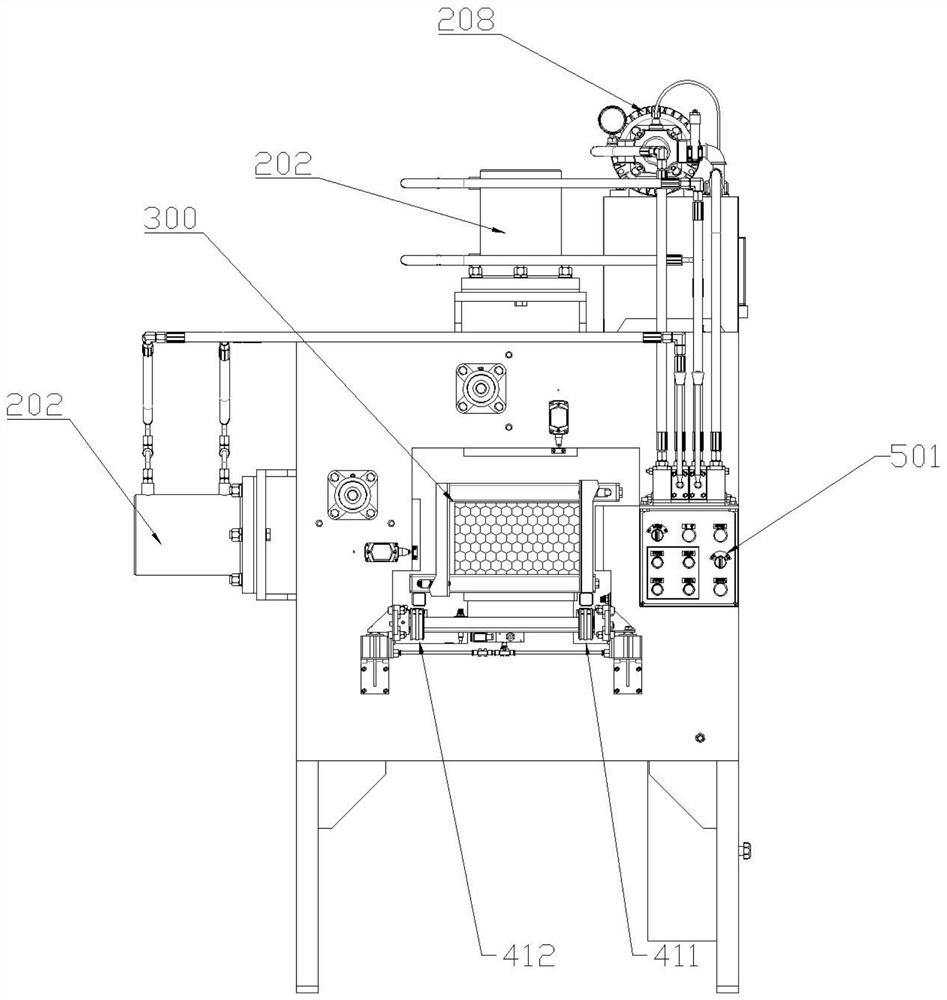

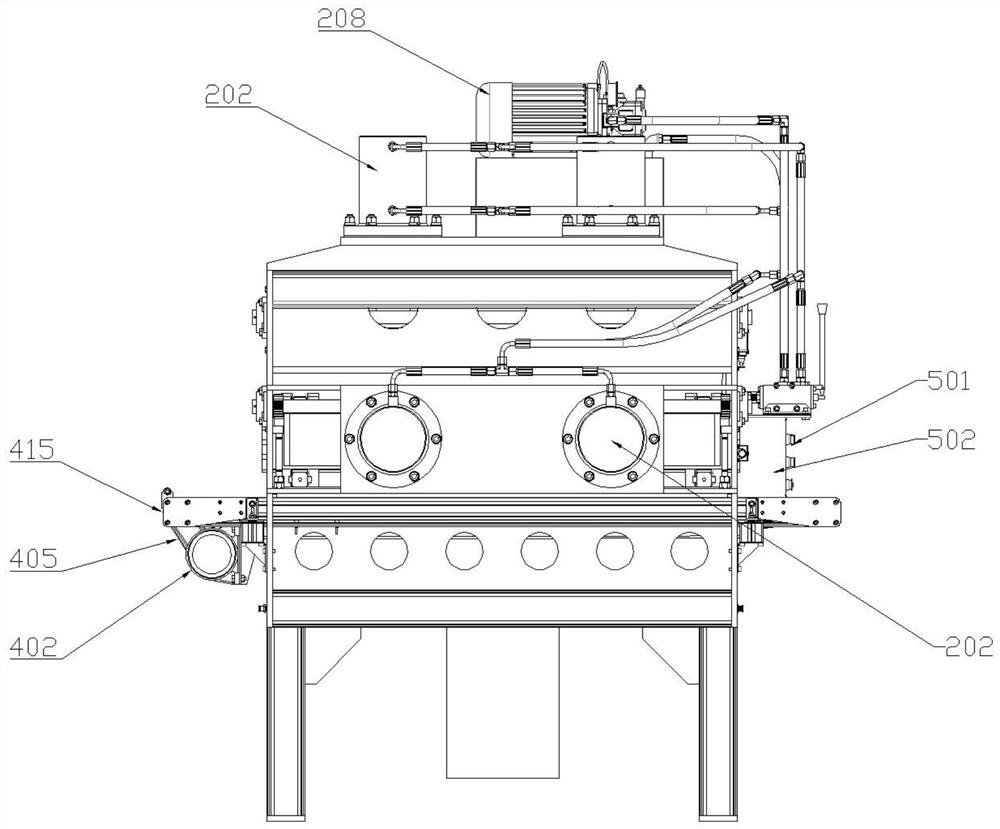

[0041] Such as Figure 1-7 As shown, a wood core blank molding machine includes: a molding machine frame 100 , a pressing device, a holding clip 300 and a feeding device 400 . in:

[0042] The holding clip 300 includes vertical feet 301 arranged on the left and right sides, and the holding clip 300 is transported on the feeding device 400 through the vertical feet 301; A plurality of first vertical plates 303 are fixed, and a plurality of second vertical plates 304 are movable on the other side. A second locking device 306 is provided at the connection between the first horizontal plate 302 and the second vertical plate 304; The upper part of the plate 303 and the second vertical plate 304 is clamped with a second horizontal plate 305, and the connection between the first vertical plate 303 and the second horizontal plate 305 is provided with a first locking device 307; the second vertical plate 304 can be opposite to the first horizontal plate. The plate 302 moves left and ...

Embodiment 2

[0048] Such as Figure 1-7 As shown, the wood core blank molding machine of this embodiment is similar to the structure of Embodiment 1, the difference is that the structure of the first locking device 307 and / or the second locking device 306 is: the first horizontal plate 302 or the second horizontal plate 305 has a first through hole 308 that runs through the first horizontal plate 302 or the second horizontal plate 305 laterally, and the second bolt 313 penetrates through one end of the first through hole 308 and can be opposite to the first horizontal plate 302 Or the second horizontal plate 305 rotates but does not produce displacement, and the position near the end of the other end of the first horizontal plate 302 or the second horizontal plate 305 is longitudinally opened with a second through hole 309, and the second through hole 309 is placed inside the first horizontal plate 309. The plate 302 or the second transverse plate 305 is vertical to the second pin 312 , th...

Embodiment 3

[0050] Such as Figure 1-7 As shown, in the wood core blank molding machine of this embodiment, on the basis of Embodiment 2, the structures of the first vertical board 303 and the second vertical board 304 are: two symmetrically arranged L-shaped boards, with a The first horizontal plate 302 and the second horizontal plate 305 have equal gaps; the first pin 310 and the second pin 312 are regular hexagonal prism structures, and the first pin 310 is provided with a groove matching the end of the first bolt 311 shank.

[0051] The pressurizing device also includes an oil pump 208, an oil delivery pipeline 209 and an oil storage tank 210. The vertical pressurization cylinder group 201 and the lateral pressurization cylinder group 202 are connected with the oil storage tank 210 through the oil delivery pipeline 209, and the oil pump 208 transfers the hydraulic oil in the oil storage tank 210 It is transported to the vertical pressurization cylinder group 201 and the lateral pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com