Flattening method for nylon film processing semi-finished product

A technology of nylon film and semi-finished products, which is applied in the field of smoothing and finishing nylon film processing semi-finished products, which can solve the problems of film surface wrinkles, uneven film thickness, film damage, etc., and achieve uniform shrinkage, low viscosity and non-volatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Include the following steps:

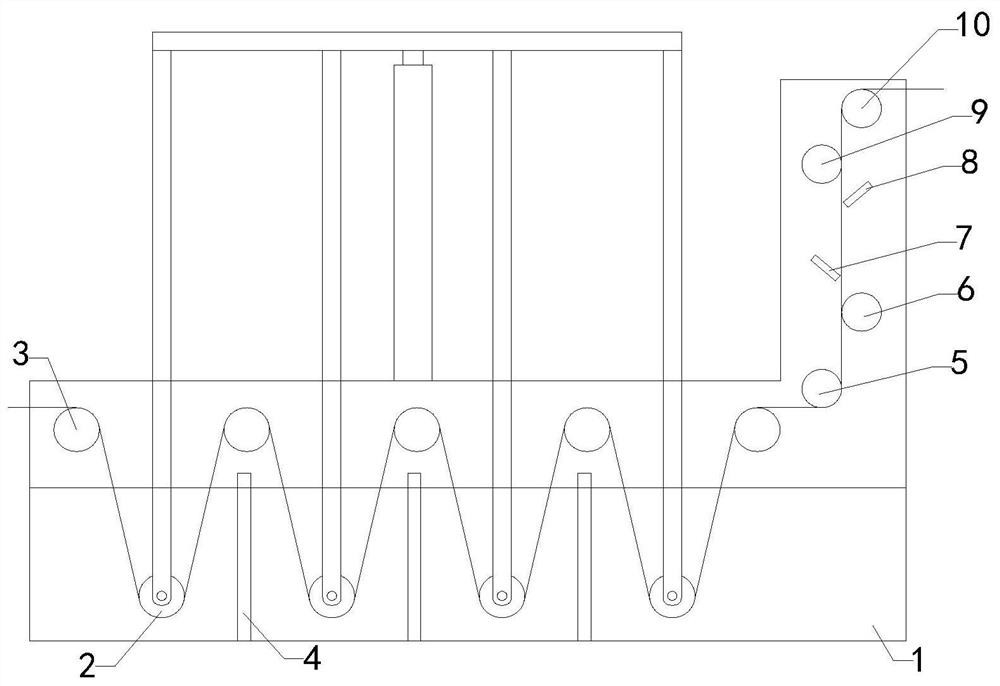

[0024] S1. Install storage box 1 at the outlet of the stretching box. The interior of storage box 1 is hollow and the top is open. The interior of storage box 1 is filled with low-toxic or non-toxic, low viscosity 1-11cps, non-volatile and water-free silicone oil. There are 4 lower rollers 2 installed in the lower half of the box 1, and the height of the 4 lower rollers 2 can be adjusted, and the 4 lower rollers 2 are all inside the silicone oil, and 5 are installed in the upper half of the storage box 1 The upper rollers 3, and the five upper rollers 3 are all above the silicone oil, and the height lifting section is set at the film outlet of the holding box 1. The height lifting section is successively the transition roller 5, which is in contact with the front of the nylon film, from bottom to top. The wiper roller 6 contacting the back side of the nylon film, the first air knife 7 towards the front of the nylon film, the second air kni...

Embodiment 2

[0028] Silicone oil is replaced by isobutanol in embodiment 1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com