Method and system for controlling environment of glass furnace based on causal reasoning

A technology for glass melting furnaces and glass furnaces, which is applied in the field of controlling the environment of glass melting furnaces based on causal reasoning. It can solve the problems that machine learning algorithms cannot explain causality, production decisions are not convincing, and the furnace environment cannot be perfectly simulated. Market value, solving the inconvenience of practical application, and the effect of simple and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

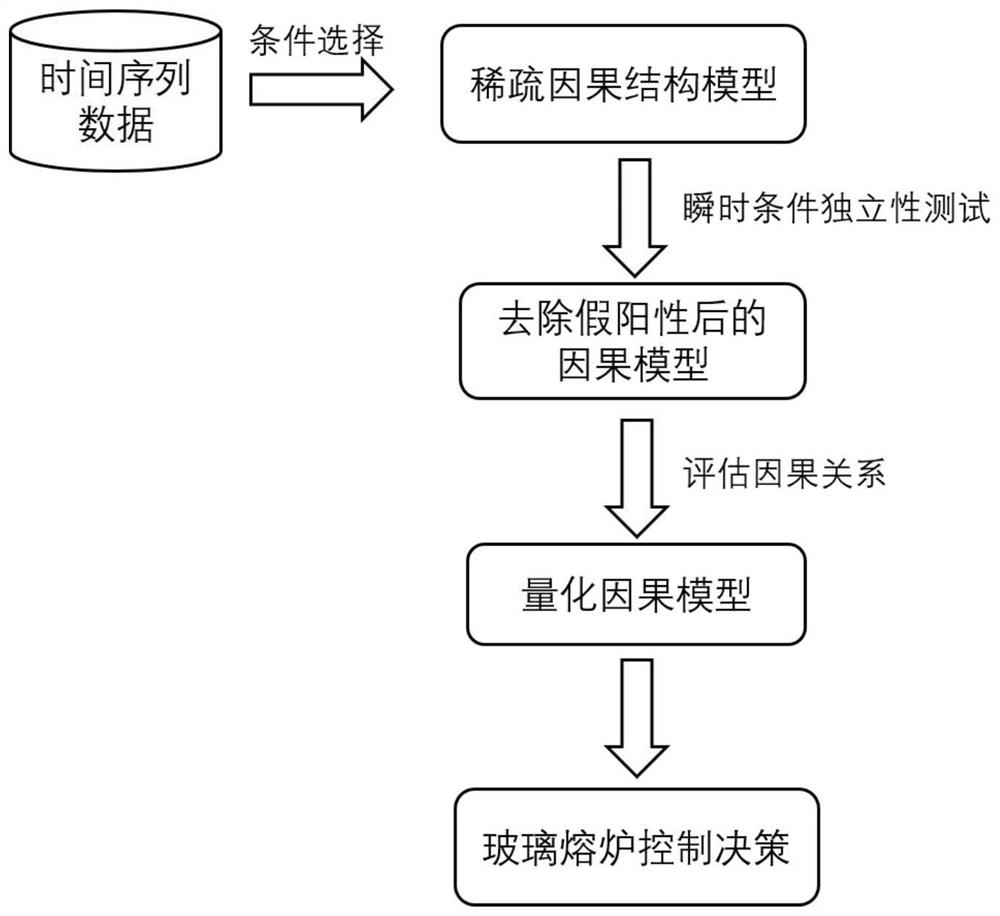

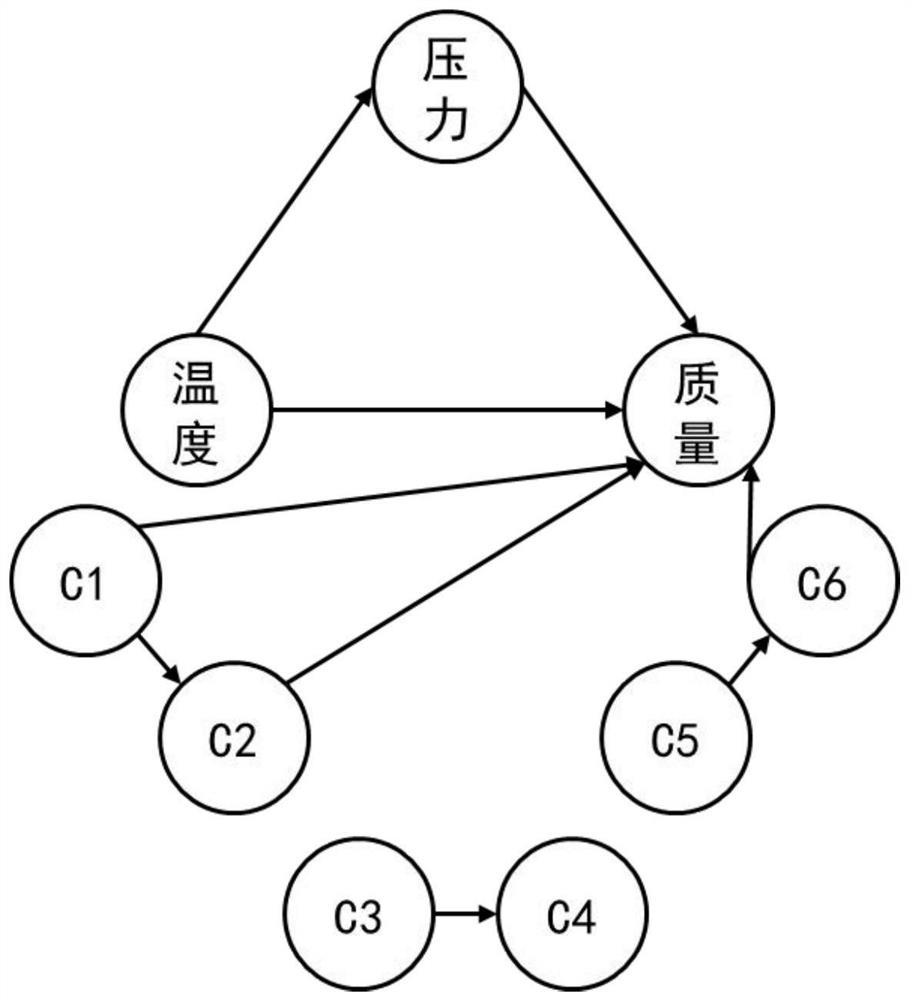

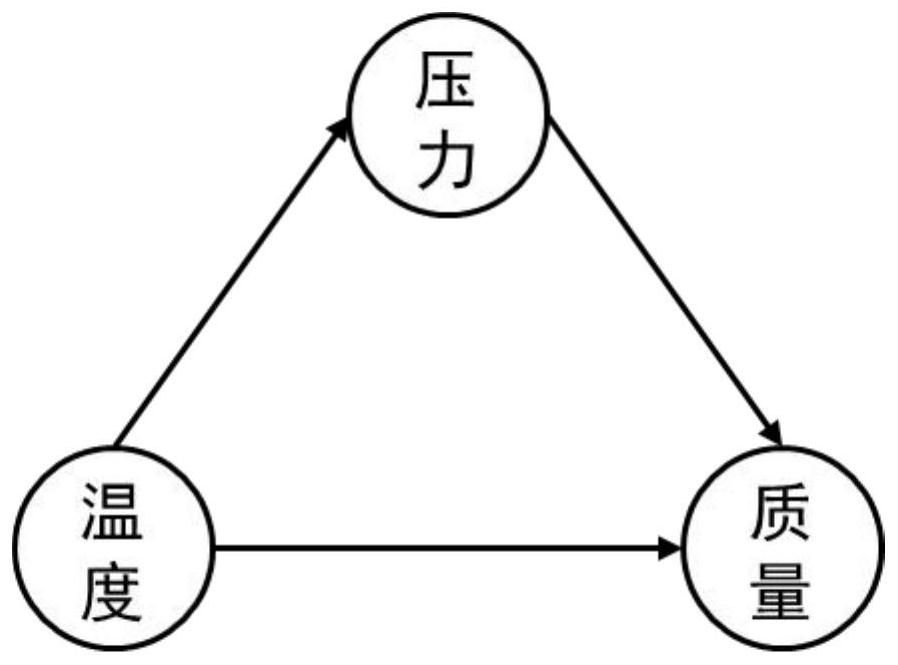

[0047]The invention provides a method for controlling the environment of a glass melting furnace based on causal reasoning, which is used for an all-oxygen glass furnace melting furnace using natural gas and oxygen as fuel. This method is based on the time series data sets of temperature, pressure, natural gas and oxygen flow, valve opening, glass melt height, furnace dust concentration, sulfur dioxide concentration, nitrogen oxide concentration and other time series data sets measured at key points in the glass melting furnace. The conditional selection algorithm deletes nodes that are conditionally independent of each other in the time series to obtain a sparse causal model. Using the obtained sparse causal model as the input of the instantaneous conditional independence test, the false positive causal association in the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com