Double-layer micro-channel heat dissipation device based on gas-liquid separation

A technology of gas-liquid separation and heat dissipation device, which is applied in cooling/ventilation/heating transformation, modification by conduction heat transfer, electrical components, etc., which can solve the instability of flow and boiling, high pressure drop, and it is difficult to further improve the critical heat flux density. and other problems to achieve the effect of suppressing instability, increasing the density of the gasification core, and eliminating instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0034] From the perspective of suppressing flow boiling instability, reducing pressure drop, increasing heat transfer coefficient and critical heat flux density, the present invention designs a high-efficiency gas-liquid separation microstructure with high stability, low pressure drop characteristics and high heat transfer performance Channel heat sink.

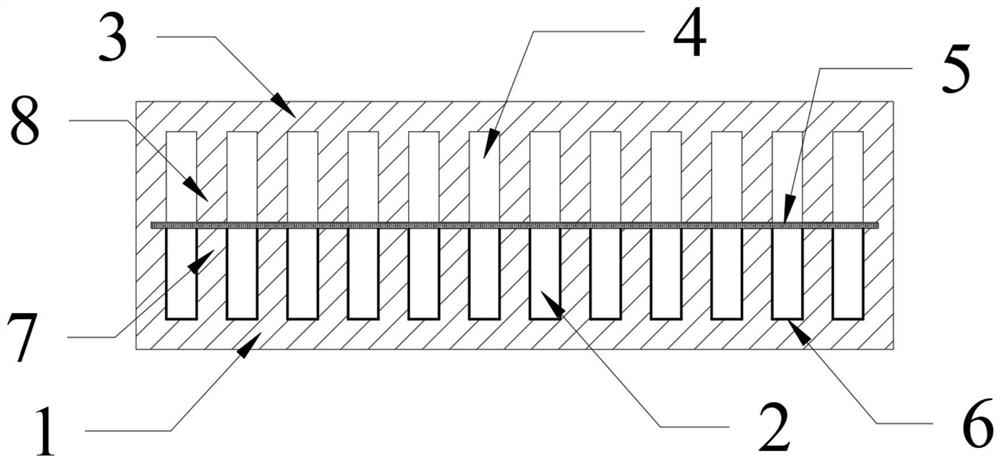

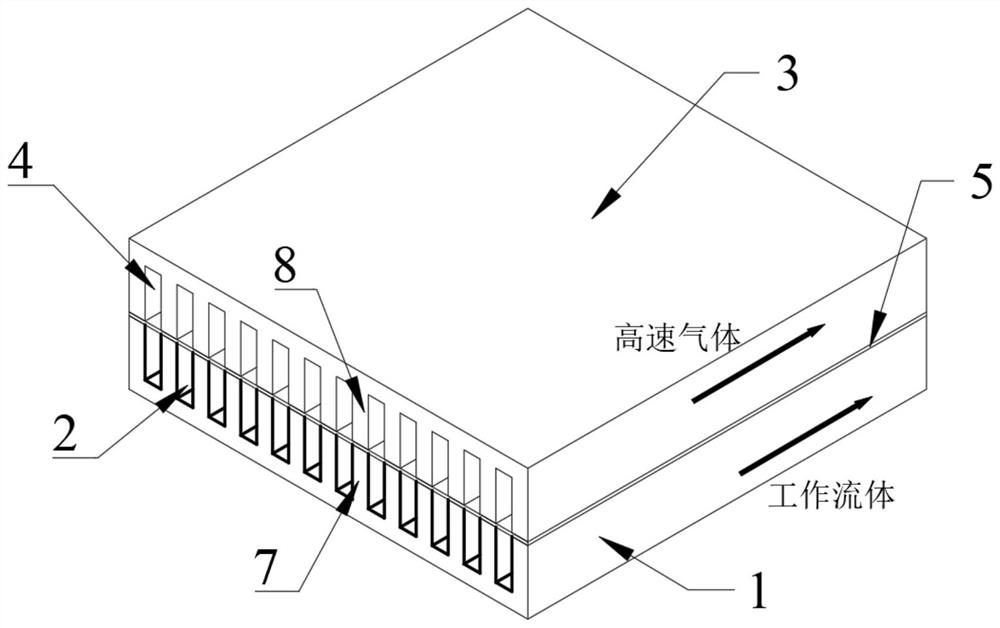

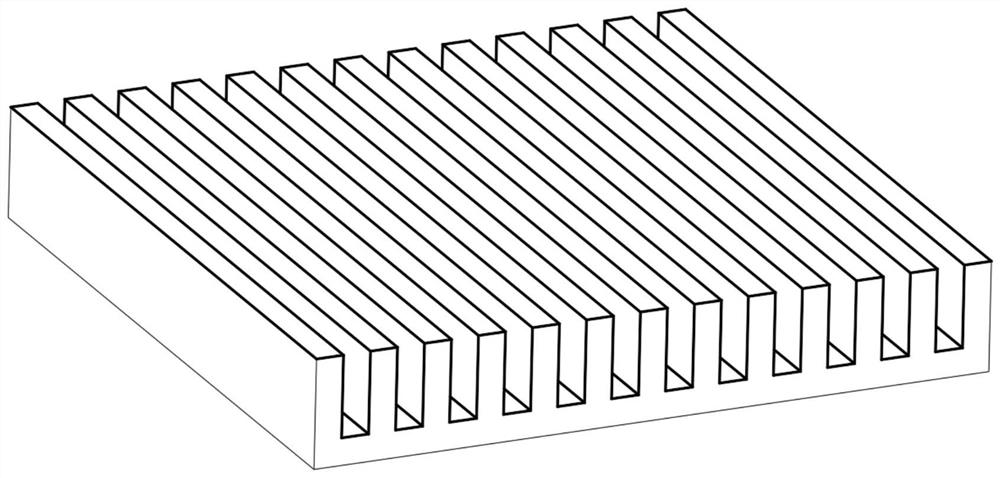

[0035] Such as Picture 1-1 , 1-2 As shown, it includes a liquid microchannel radiator 1, a liquid microchannel 2, an air microchannel radiator 3, an air microchannel 4, a nanoporous film 5, a porous structure 6 on the surface of the liquid microchannel and the first micro Rib 7 and second micro-rib 8 . Based on the principle of rapid gas-liquid separation, the present invention proposes a structural design of double-layer microchannels for gas-liquid separation, which mainly consists of upper and lower layers of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com