Method for reducing oxygen content in halide molten salt

A technology of halide and oxygen content, applied in the preparation of fluoride, chloride, bromide, etc., can solve the problems of strong equipment corrosion, low treatment efficiency, long time consumption, etc., and achieve weak equipment corrosion and treatment. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

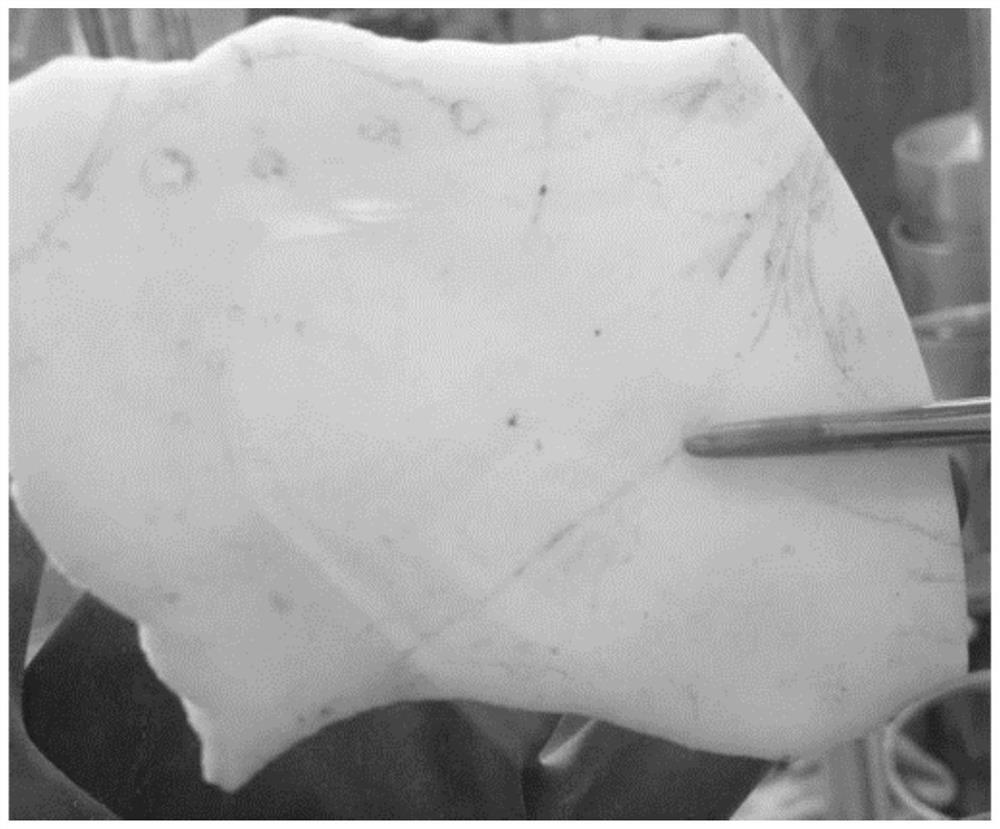

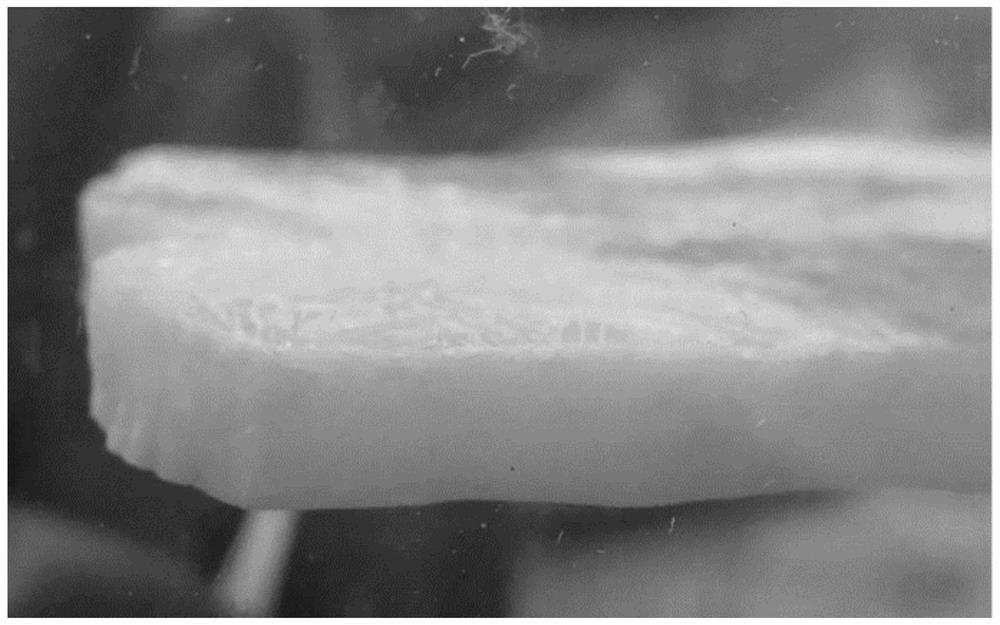

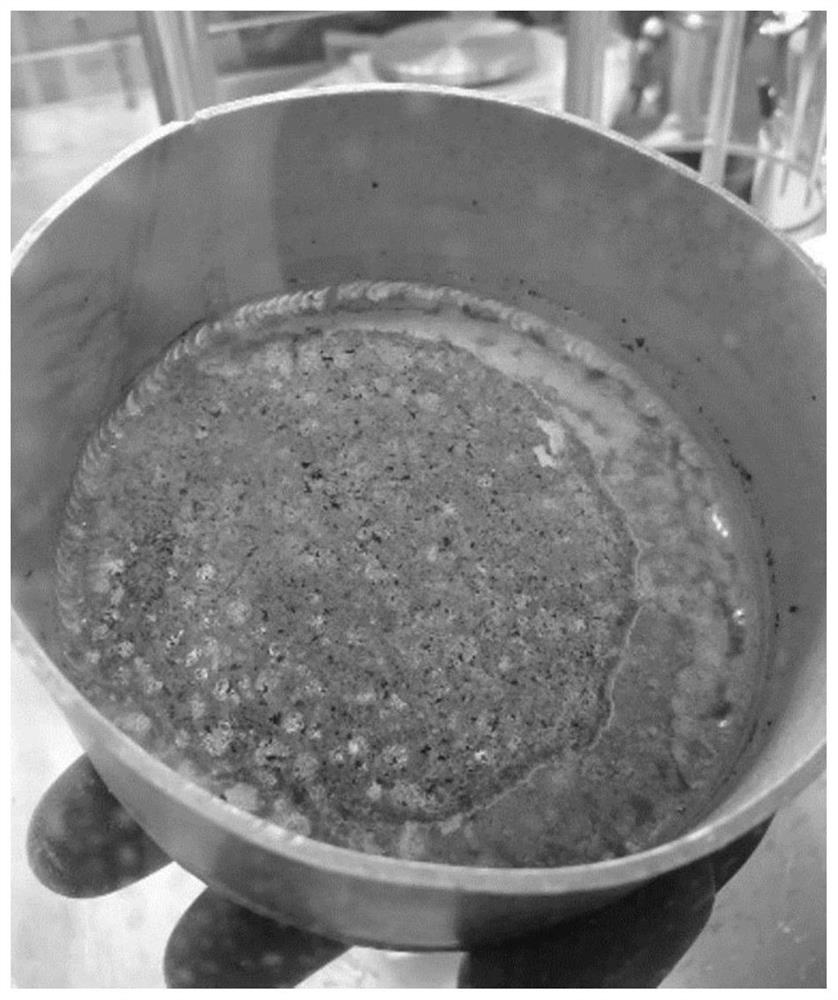

Image

Examples

Embodiment 1~5

[0107] The halide molten salt in embodiment 1, 3 and 4 is the self-made simulated molten salt reactor fuel carrier salt; The halide molten salt in embodiment 2 is the used halide molten salt of molten salt battery; Molten salt is the halide molten salt used in molten salt reactors.

[0108] Among the embodiments 1-5, the method for reducing the oxygen content in the halide molten salt comprises the following steps:

[0109] (1) After pulverizing the halide molten salt, under an inert atmosphere, fill the furnace cavity of the evaporation furnace body with inert gas, and place the pulverized halide molten salt in the evaporation crucible of the distillation equipment In, sealed;

[0110] (2) Set the vacuum degree of the distillation equipment;

[0111] (3) The distillation temperature, condensation temperature and distillation time of the distillation equipment are set, and the halide molten salt is distilled;

[0112] (4) After the distillation process is finished, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com