Method for cleaning liner of semiconductor etching machine

A semiconductor and machine technology, used in cleaning methods and utensils, chemical instruments and methods, and dust removal, etc., can solve problems such as cleaning the inner surface of complex structures, and achieve the effect of improving efficiency and surface quality and avoiding loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

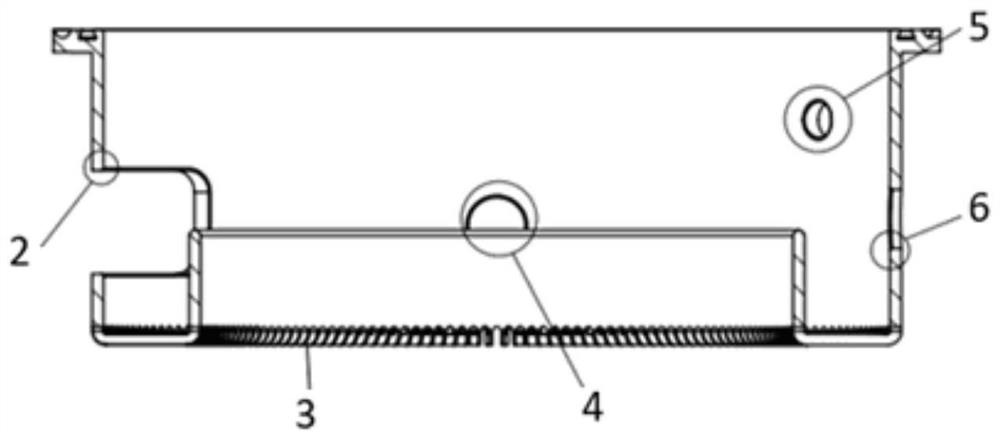

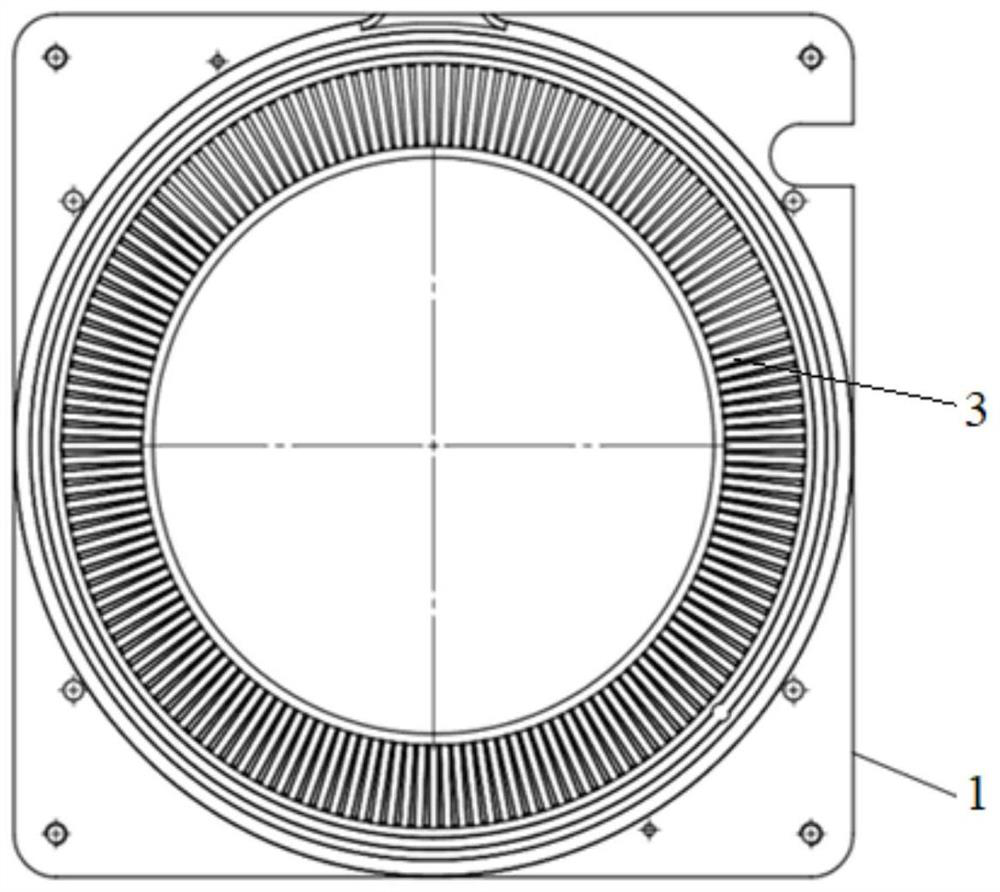

[0021] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

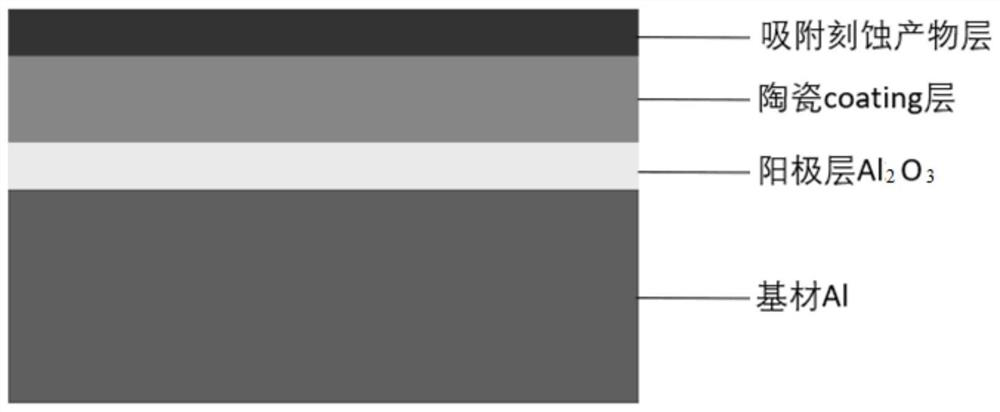

[0022] The invention relates to a method for cleaning the inner liner of a semiconductor etching machine using micropowder blasting. Sandblasting stripping is used in surface treatment and component cleaning to completely remove a small amount of residue or natural adsorption layer on the surface of the component. Sandblasting stripping is under a certain air pressure, through the compressed air flow, the gravel is driven to impact on the surface of the object to be treated, and the impact force of the gravel will sputter and peel off the attached substances on the surface of the object to be treated, which will cause certain physic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com