Preparation method of electroplated diamond grinding wheel

A technology of electroplating diamond and diamond, which is applied in the direction of metal processing equipment, electrolytic coating, manufacturing tools, etc., can solve the problems of uneven distribution of abrasives, cumbersome operation, and low efficiency of sanding, and achieve uniform distribution of abrasives, uniform distribution, and sanding high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation method of the present invention will be further described below in conjunction with the accompanying drawings and specific examples.

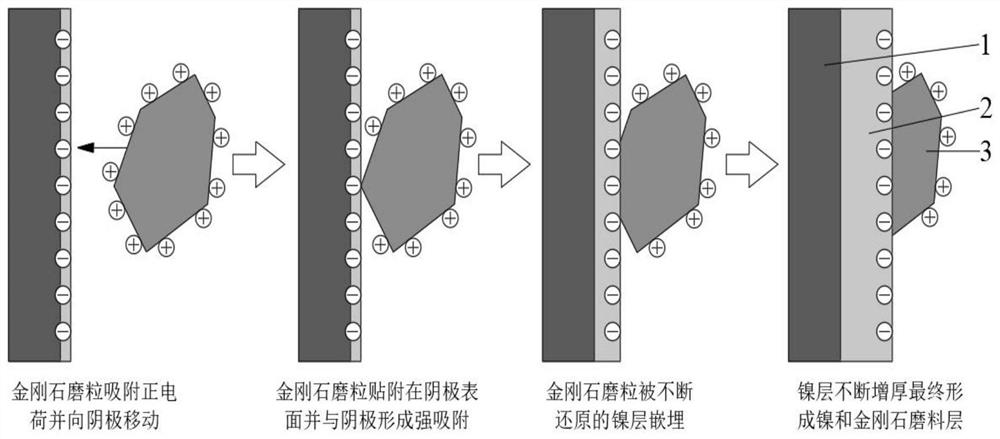

[0025] A preparation method of a composite coated superhard grinding wheel is as follows.

[0026] Step 1: polishing, pickling and derusting the wheel hub 1, and coating the non-working surface with insulating varnish; the polishing process is: polishing the wheel hub 1 with 200 mesh, 400 mesh and 800 mesh sandpaper respectively; rust removal process For: at a temperature of 25° C., soak the hub 1 in hydrochloric acid solution for 180 seconds, and then wash it with distilled water.

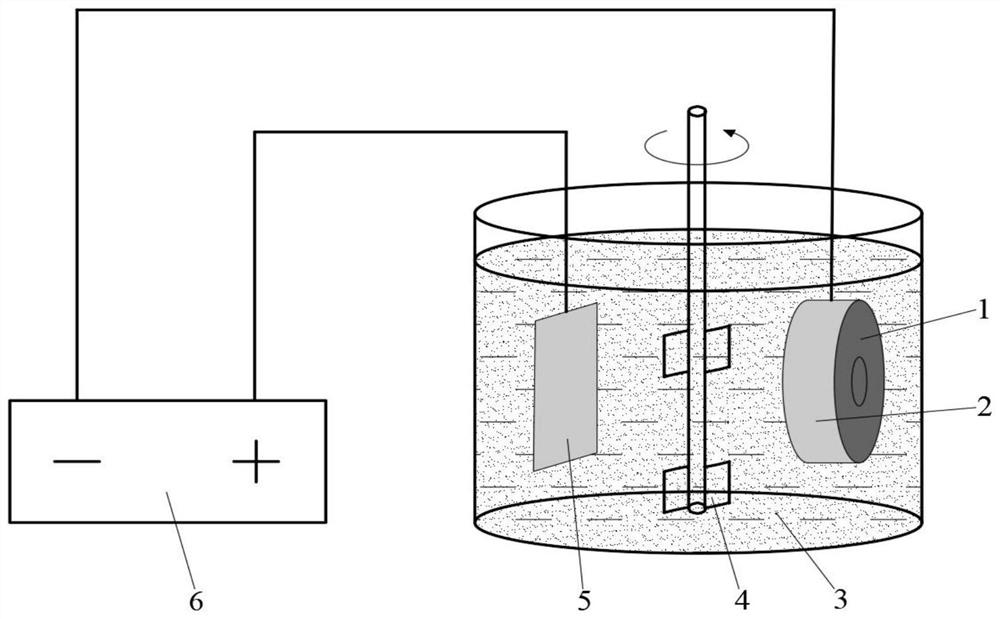

[0027] Step 2: NiSO at 260g / L 4 ·6H 2 O solution, add 35g / L of H 2 BO 3 and 20g / L NiCl 2 ·6H 2 O is used as a buffer and an anode activator to form a plating solution respectively, with the hub 1 as the cathode and the pure nickel plate 5 as the anode, and a 2 μm Ni layer 2 is pre-plated on the working surface of the hub 1; other ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com