Filler reinforcement-based low-consumption and high-efficiency sewage treatment unit and system

A sewage treatment and enhanced treatment technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, granular microbial carrier treatment, etc., can solve the problem of large floor area, high investment and operating costs, and low treatment efficiency and other problems, to achieve the effect of flexible and diverse water outlet methods, good sewage treatment effect, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

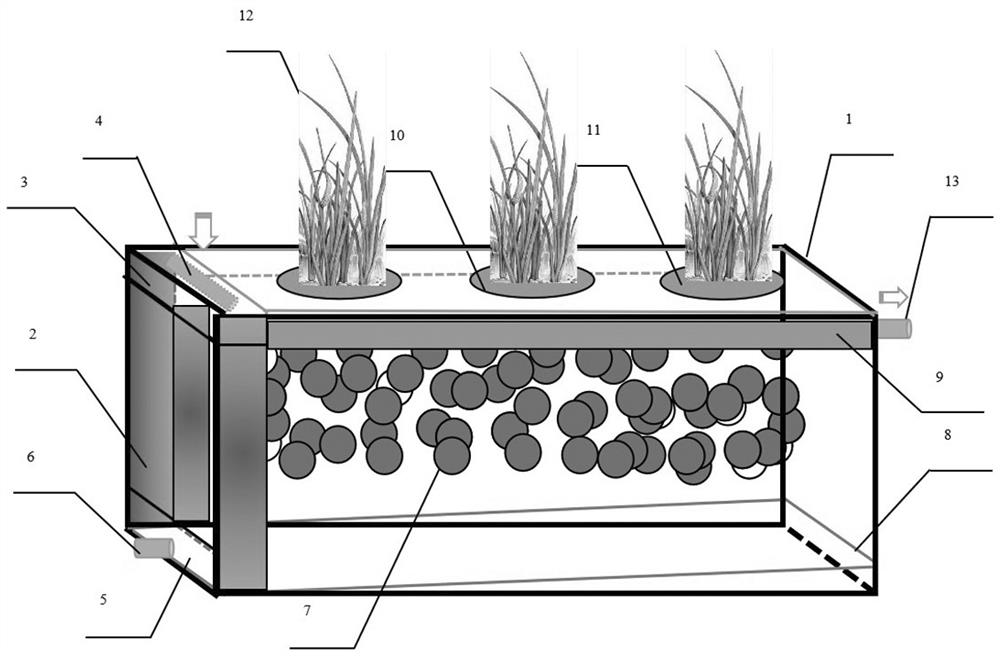

[0027] Embodiment 1: This embodiment is a low-consumption and high-efficiency sewage treatment system based on filler reinforcement, which is composed of several low-consumption and high-efficiency sewage treatment units based on filler reinforcement in series, parallel or series-parallel combination. The application scenario of the sewage treatment system is on the shore or on the water surface, and when it is applied on the water surface, it is divided into one of fixed or floating or a combination of both.

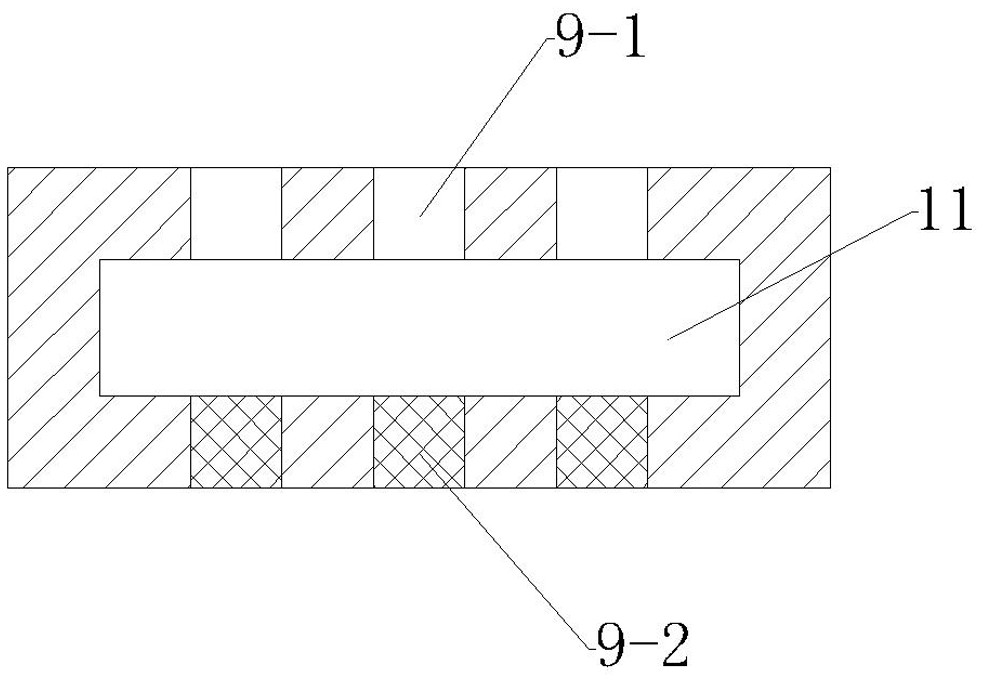

[0028] In this example, the low-consumption and high-efficiency sewage treatment unit based on filler reinforcement has a sewage treatment frame whose shape is a cube, cuboid or cylinder, and when it is a long (square) cube, the length, width and height specifications are (1~10): (1~5): 1, and the ratio of diameter to height is not less than 0.3 when it is a cylinder. The sewage treatment frame chooses modular structure or civil engineering (unit) layout according to ac...

Embodiment 2

[0041] Embodiment 2: This embodiment selects a section of relatively closed river channel based on the technology of embodiment 1 to carry out a comparison and demonstration of on-shore technology. The specific process is to set two groups of equipment with the same specifications as the control group and the experimental group (the processing scale is 5t / d), The only difference between the control group and the experimental group based on this embodiment is that the control group does not divide into various functional areas, and the filler filled is melon rice gravel (particle size: 25mm) which is common in traditional constructed wetlands. During the experiment, the polluted river water was pumped to the sewage treatment system for treatment and then discharged into the river to investigate the CODCr, TN and TP removal effects of the two test systems.

[0042] In this embodiment, the shape of the sewage treatment frame is a cuboid, and the specification is 3m*1m*1m. The fram...

Embodiment 3

[0051] Embodiment 3: The structure and parameters of Embodiment 3 are the same as those of Embodiment 2. The only difference is that an auxiliary and expansion module is set on the test group. The selected expansion module is an aeration system, and its external aeration pipe is fixedly installed on the Adjustable grit settling mechanism. Among them, the length of the aeration pipe is 2.5m, and 4 aeration pipes are evenly arranged, and the diameter of the aeration pipe is 25mm, and the holes are opened on both sides at an angle of 45°, and the aeration rate is 70L / min.

[0052] In this embodiment, the removal effect of the experimental group to pollutants is significantly better than that of the control group, wherein the removal rates of the experimental group to CODCr, TN and TP are 88.39%, 98.93% and 51.44% respectively; The removal rates were 28.44%, 64.27% and 20.41%, respectively; in addition, after 15 days of stable operation, the amount of microbial film formation in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com