Pearl bone china glaze water preparation method

A technology of bone china and glaze water, used in glass manufacturing equipment, manufacturing tools, glass furnace equipment, etc., can solve the problems of whiteness and brightness difference, and achieve the effect of increasing or decreasing whiteness and brightness, good gloss, and speeding up the removal of pores. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

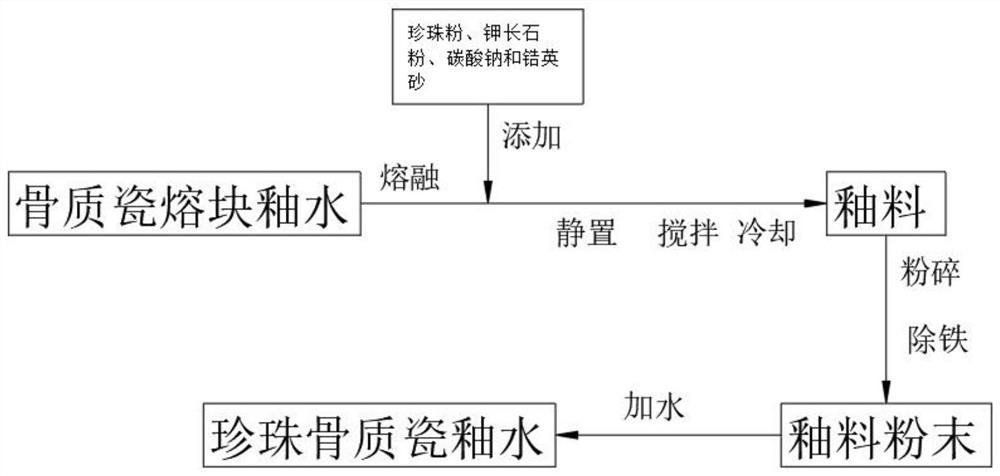

[0026] see figure 1 , the present invention provides a kind of technical scheme: the preparation method of pearl bone china glaze water: the preparation method of this pearl bone china glaze water is as follows:

[0027] Step 1: Select 60 to 65 parts of silicon dioxide, 22 to 24 parts of aluminum oxide, 29 to 31 parts of potassium carbonate, 21 to 25 parts of borax and 29 to 36 parts of sodium silicate in parts by weight, and then mix calcium phosphate, Melt and mix silicon, alumina, potassium carbonate, borax and sodium silicate to obtain bone china frit glaze;

[0028] Step 2: select 5 to 10 parts of pearl powder, 3 to 5 parts of potassium feldspar powder, 4 to 5 parts of sodium carbonate, and 0 to 1 part of zircon sand according to parts by weight, and mix pearl powder, potassium feldspar powder, sodium carbonate and zirconium Add English sand to bone china frit glaze water and let it stand;

[0029] Step 3: After the pearl powder, potassium feldspar powder, sodium carbon...

Embodiment 2

[0032] see figure 1 , the present invention provides a kind of technical scheme: the preparation method of pearl bone china glaze water: the preparation method of this pearl bone china glaze water is as follows:

[0033] Step 1: Select 75 to 80 parts of silicon dioxide, 27 to 30 parts of aluminum oxide, 36 to 42 parts of potassium carbonate, 32 to 35 parts of borax and 12 to 18 parts of sodium silicate in parts by weight, and then mix calcium phosphate, Melt and mix silicon, alumina, potassium carbonate, borax and sodium silicate to obtain bone china frit glaze;

[0034] Step 2: select 15 to 20 parts of pearl powder, 8 to 10 parts of potassium feldspar powder, 2 to 3 parts of sodium carbonate, and 2 to 3 parts of zircon sand according to parts by weight, and mix pearl powder, potassium feldspar powder, sodium carbonate and zirconium Add English sand to bone china frit glaze water and let it stand;

[0035] Step 3: After the pearl powder, potassium feldspar powder, sodium car...

Embodiment 3

[0038] see figure 1 , the present invention provides a kind of technical scheme: the preparation method of pearl bone china glaze water: the preparation method of this pearl bone china glaze water is as follows:

[0039] Step 1: Select 65 to 75 parts of silicon dioxide, 24 to 27 parts of aluminum oxide, 31 to 36 parts of potassium carbonate, 25 to 32 parts of borax and 18 to 29 parts of sodium silicate in parts by weight, and then mix calcium phosphate, Melt and mix silicon, alumina, potassium carbonate, borax and sodium silicate to obtain bone china frit glaze;

[0040] Step 2: Select 10-15 parts of pearl powder, 5-8 parts of potassium feldspar powder, 3-4 parts of sodium carbonate, and 1-2 parts of zircon sand according to parts by weight, and mix pearl powder, potassium feldspar powder, sodium carbonate and zirconium Add English sand to bone china frit glaze water and let it stand;

[0041] Step 3: After the pearl powder, potassium feldspar powder, sodium carbonate and zi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com