Graphite expansion ramming material as well as preparation method and use method thereof

A technology of ramming material and graphite, applied in the direction of furnace, blast furnace details, furnace type, etc., can solve the problems of dislocation of refractory materials, loss of cooling contacts, reduction of cooling efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

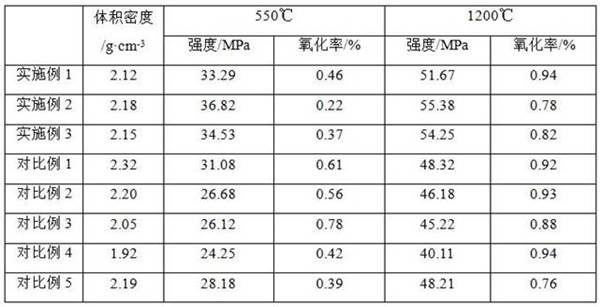

Examples

preparation example Construction

[0030] The embodiment of the present invention also provides a kind of preparation method of above-mentioned graphitic expanded ramming material, it comprises:

[0031] S1. mixing the first flake graphite, the second flake graphite, and the third flake graphite in proportion to obtain flake graphite;

[0032] S2. uniformly mixing flake graphite and silicon carbide powder to obtain a mixed powder;

[0033] S3. Knead the mixed powder with medium temperature modified asphalt and anthracene oil.

[0034] Preferably, the kneading temperature is 80-100° C., and the kneading time is 1-2 h. After kneading, let it cool to room temperature and pack it into a bag.

[0035] Further, the mass ratio of mixed powder, medium temperature modified asphalt and anthracene oil is 75:15:10. Under the above ratio, the obtained graphite expanded ramming material has better plasticity at room temperature, and at the same time, when the temperature rises to 200°C, it can expand rapidly and has high ...

Embodiment 1

[0042] The present embodiment provides a graphite expansion ramming material, which comprises in parts by weight:

[0043] 65 parts of flake graphite, 10 parts of silicon carbide powder, 12 parts of medium temperature modified pitch, 8 parts of anthracene oil;

[0044] Wherein, the flake graphite includes the first flake graphite, the second flake graphite, and the third flake graphite; the particle diameter of the first flake graphite is 2-4 mm, and the particle diameter of the second flake graphite is 0.08-2 mm; the third flake graphite The particle size of the graphite is <0.08 mm; the mass ratio of the first flake graphite, the second flake graphite, and the third flake graphite is 1:2.2:1.8; the particle size of the silicon carbide powder is 0.05-2 mm.

[0045] The preparation method of this graphite expanded ramming material is as follows:

[0046] S1. mixing the first flake graphite, the second flake graphite, and the third flake graphite in proportion to obtain flake ...

Embodiment 2

[0050] The present embodiment provides a graphite expansion ramming material, which comprises in parts by weight:

[0051]70 parts of flake graphite, 5 parts of silicon carbide powder, 18 parts of medium temperature modified pitch, 8 parts of anthracene oil;

[0052] Wherein, the flake graphite includes the first flake graphite, the second flake graphite, and the third flake graphite; the particle diameter of the first flake graphite is 2-4 mm, and the particle diameter of the second flake graphite is 0.08-2 mm; the third flake graphite The particle size of the graphite is <0.08 mm; the mass ratio of the first flake graphite, the second flake graphite, and the third flake graphite is 1:2.6:1.3; the particle size of the silicon carbide powder is 0.05-2 mm.

[0053] The preparation method of this graphite expanded ramming material is as follows:

[0054] S1. mixing the first flake graphite, the second flake graphite, and the third flake graphite in proportion to obtain flake gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap