Cell culture device

A cell culture and incubator technology, which is applied in tissue cell/virus culture devices, biochemical cleaning devices, enzymology/microbiology devices, etc., can solve problems such as pollution, internal pollution, and reduced success rate of culture, and achieve improved Survival rate, effect of pollution prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

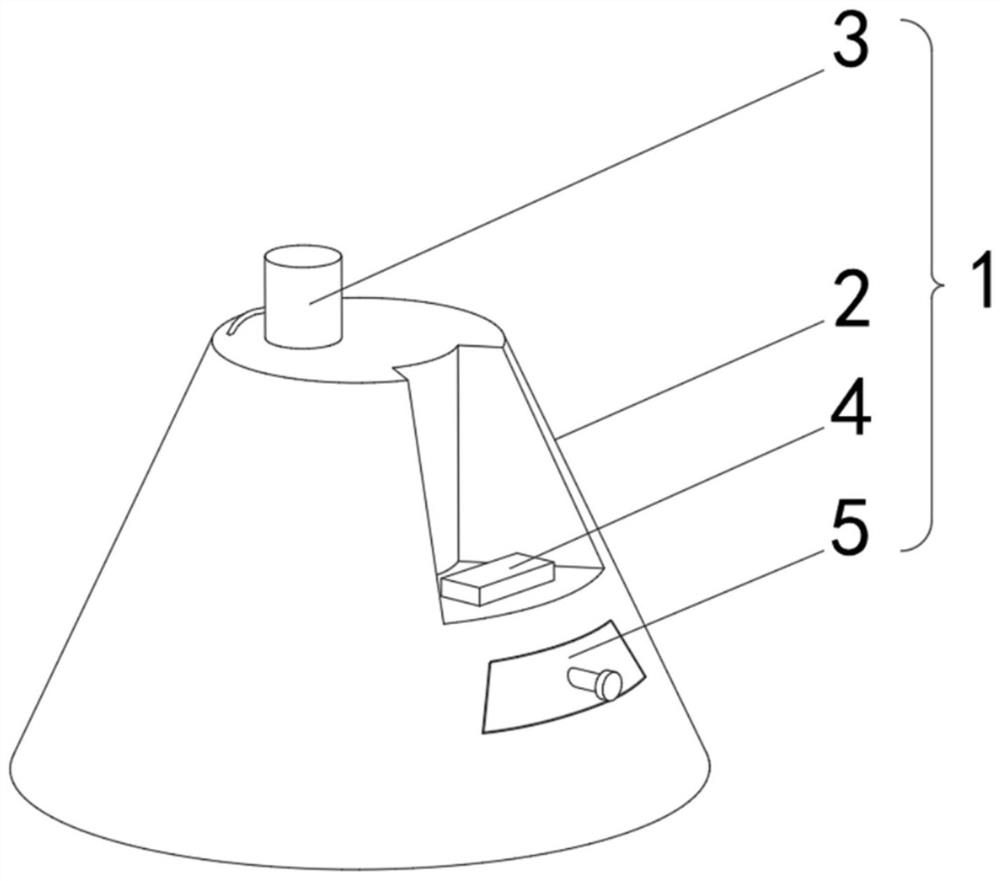

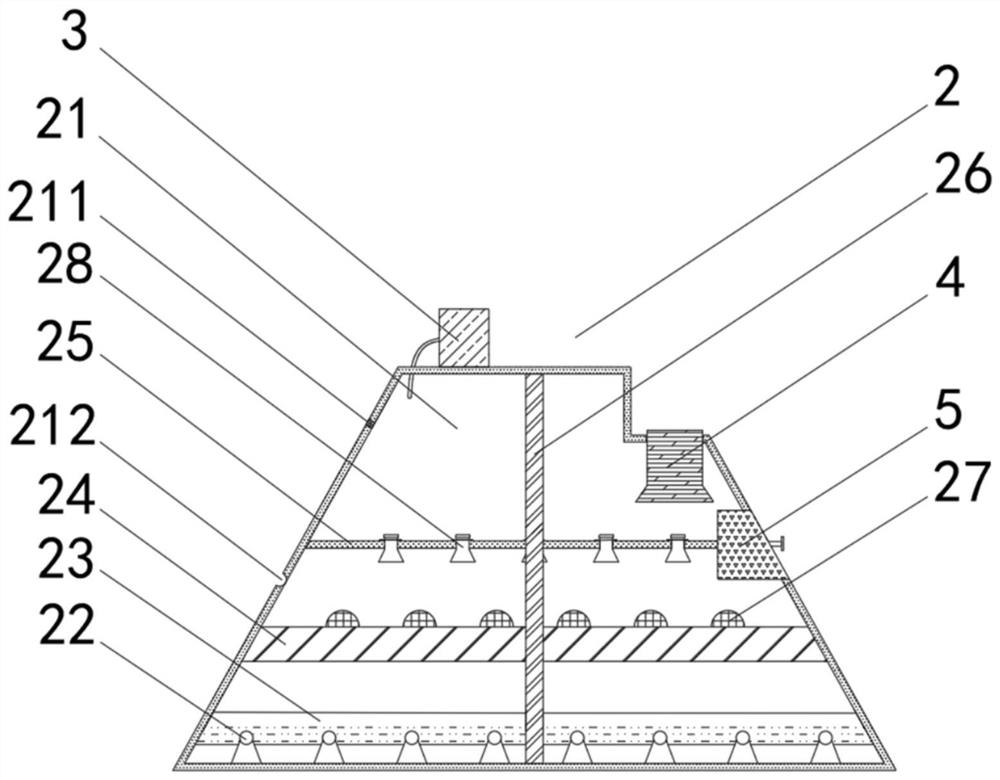

[0042] see Figure 1-2 , the present invention provides a technical solution: a cell culture device, including a cell culture device body 1 composed of an incubator 2, an oxygen storage tank 3, an observation mechanism 4 and a debugging mechanism 5, and a culture chamber 21 is provided inside the incubator 2 , the bottom of the inner wall of the culture cavity 21 is fixedly connected with a heating mechanism 22, and the top of the heating mechanism 22 is connected with a water storage tank 23, and the top of the water storage tank 23 is successively provided with an air jet plate 24 and a cultivation frame 25, and the outside of the air jet plate 24 is connected with the cultivation The inner wall of the cavity 21 is fixedly connected, and the inside of the cultivation cavity 21 is provided with a rotating rod 26, and the outside of the rotating rod 26 is fixedly connected with the inside of the cultivation frame 25, and the top of the air jet plate 24 is provided with an air i...

Embodiment 2

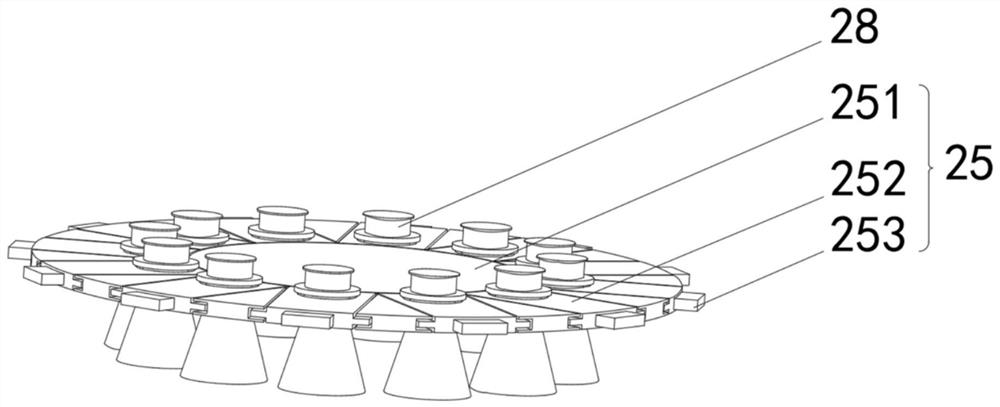

[0046] see Figure 1-5 On the basis of Embodiment 1, the present invention provides a technical solution: the culture frame 25 includes a culture plate 251, the inside of the culture plate 251 is slidably connected with a culture support plate 252, and the inside of the culture support plate 252 is slidably connected with the culture dish 28 The outer side of the culture support plate 252 is fixedly connected with a magnetic bar 253 , the outer side of the culture tray 251 is fixedly connected with the inner wall of the culture cavity 21 , and the inside of the culture tray 251 is fixedly connected with the rotating rod 26 .

[0047] The observation mechanism 4 includes an observation frame 41. The outside of the observation frame 41 is fixedly connected to the inside of the incubator 2. The bottom of the observation frame 41 runs through the incubator 2 and extends to the inside of the incubator 2. The inside of the observation frame 41 is sequentially arranged from top to bot...

Embodiment 3

[0052] see Figure 1-8 , On the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the air injection mechanism 27 includes an air injection block 271, an air delivery pipe 272 is arranged inside the air injection block 271, and an air injection valve is fixedly connected to the top of the air injection block 271 273, the top of the air delivery pipe 272 communicates with the air injection valve 273, the bottom of the air delivery pipe 272 communicates with an air delivery ring block 274, and the bottom of the air injection block 271 is provided with a slow flow groove 275.

[0053] The gas transmission ring block 274 includes a receiving bar 2741, the outer side of the receiving bar 2741 is fixedly connected with the inside of the air injection block 271, and the inner part of the receiving bar 2741 is provided with a receiving port 2742, and the receiving port 2742 communicates with the bottom of the gas delivery pipe 272, and the rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com