Composite reinforced aluminum magnesium alloy material

An aluminum-magnesium alloy, composite reinforcement technology, applied in nanotechnology for material and surface science, metal processing equipment, nanotechnology, etc., can solve problems such as particle reinforcement agglomeration, achieve improved compatibility, good acid resistance, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

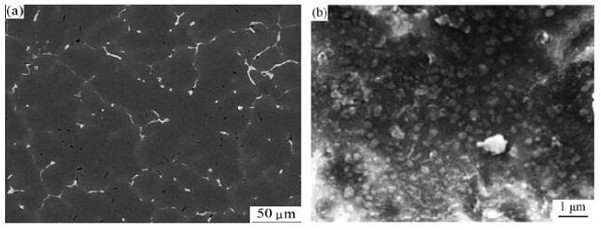

Image

Examples

Embodiment 1

[0042] A method for preparing a composite reinforced aluminum-magnesium alloy material, comprising the following steps:

[0043] (1) Put 200g of aluminum ingot into the crucible in the resistance furnace and raise the temperature to 700°C, keep it warm until the aluminum ingot is completely melted;

[0044] (2) Add 30g of magnesium ingots in 3 times and stir. After the magnesium ingots are completely added, use a spiral stirring rod to stir at a speed of 500r / min for 5min;

[0045] (3) Continue to increase the stirring speed to 600r / min, and slowly add 0.1g of biotemplate-based gold nanoparticles and 5g of silkworm excrement biochar-loaded silicon particles to the melt by using the vortex formed by stirring and stir for 30min;

[0046] (4) After the temperature of the melt is stable, perform ultrasonic treatment for 15 minutes. After the treatment, raise the temperature of the melt to 750°C and keep it warm, and cast it into a mold.

[0047] The preparation method of gold nan...

Embodiment 2

[0065] A method for preparing a composite reinforced aluminum-magnesium alloy material, comprising the following steps:

[0066] (1) Put 200g of aluminum ingot into the crucible in the resistance furnace and raise the temperature to 700°C, keep it warm until the aluminum ingot is completely melted;

[0067] (2) Add 35g of magnesium ingots in 3 times and stir. After the magnesium ingots are completely added, use a spiral stirring rod to stir at a speed of 500r / min for 6min;

[0068] (3) Continue to increase the stirring speed to 600r / min, and slowly add 0.15g of biotemplate-based gold nanoparticles and 6g of silkworm excrement biochar-loaded silicon particles to the melt by using the vortex formed by stirring and stir for 35min;

[0069] (4) After the temperature of the melt is stable, perform ultrasonic treatment for 15 minutes. After the treatment, raise the temperature of the melt to 750°C and keep it warm, and cast it into a mold.

[0070] The preparation method of gold na...

Embodiment 3

[0088] A method for preparing a composite reinforced aluminum-magnesium alloy material, comprising the following steps:

[0089] (1) Put 200g of aluminum ingot into the crucible in the resistance furnace and raise the temperature to 700°C, keep it warm until the aluminum ingot is completely melted;

[0090] (2) Add 40g of magnesium ingots in 3 times and stir. After the magnesium ingots are completely added, use a spiral stirring rod to stir at a speed of 500r / min for 5-8min;

[0091] (3) Continue to increase the stirring speed to 600r / min, and slowly add 0.2g of biotemplate-based gold nanoparticles and 8g of silkworm excrement biochar-loaded silicon particles to the melt by using the vortex formed by stirring and stir for 35min;

[0092] (4) After the temperature of the melt is stable, perform ultrasonic treatment for 15 minutes. After the treatment, raise the temperature of the melt to 750°C and keep it warm, and cast it into a mold.

[0093] The preparation method of gold n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com