Waste aluminum regenerated high-strength and high-toughness aluminum alloy and preparation method thereof

An aluminum alloy and aluminum regeneration technology, applied in the field of aluminum alloy, can solve the problems of high production cost of cast aluminum alloy, restrict the application of cast aluminum alloy, low strength, etc., and achieve the effects of improving strength and plasticity, reducing production cost and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

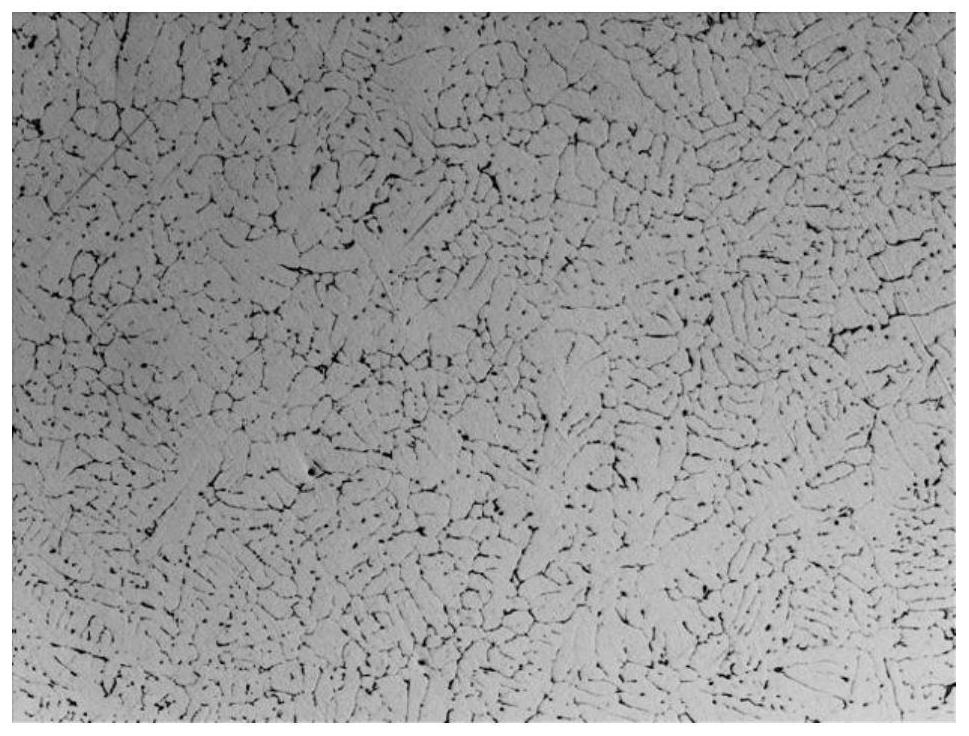

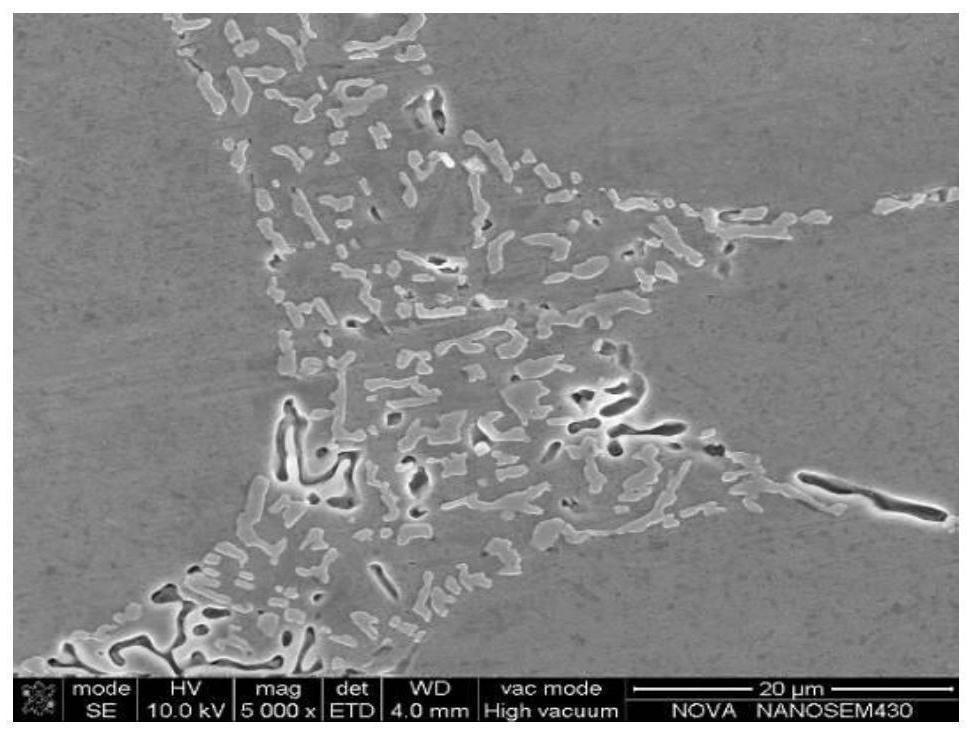

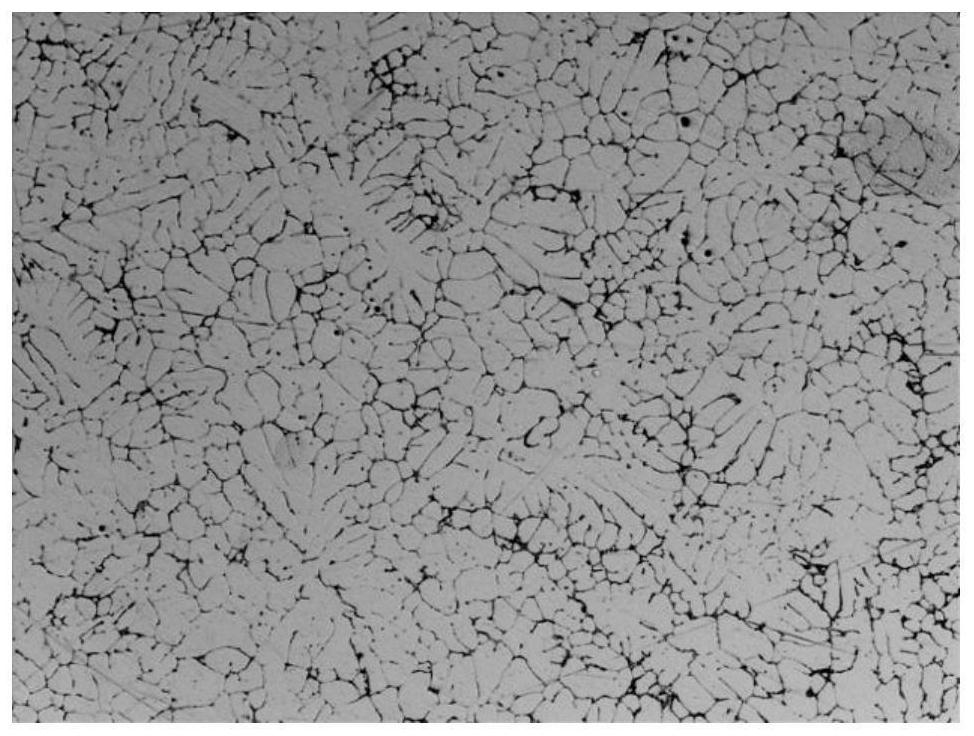

Image

Examples

Embodiment 1

[0070] The aluminum alloy consists of the following mass percentage of ingredients: Si 8.74%, Mg 0.36%, Fe 0.64%, CR0.037%, Ti 0.030%, BA 0.030%, C 0.004%, B 0.005% The balance is Al and impurity elements, and the monocity of impurity elements is ≤0.05%, and the total amount is ≤0.15%.

[0071] The aluminum alloy is used to regenerate, including the following steps:

[0072] (1) Select waste car motor shell, waste motorcycle wheel, waste ship aluminum plate, waste mobile shell, aluminum nickel carbon alloy, barium barium alloy and aluminum boron alloy as raw materials;

[0073] (2) Waste automotive motor shells will account for 68% of the total amount of raw materials, 22% of the waste motorcycle hub, 6% waste ship aluminum plate and 3.2% of the waste mobile shell are heated into an aluminum alloy liquid at 740 ° C;

[0074] (3) Adding an aluminum nickel-carbon alloy having a total amount of 0.4% of the total weight of the raw material, 0.3% aluminum barium alloy and 0.1% aluminum...

Embodiment 2

[0080] Aluminum alloy consists of the following mass percentage of ingredients: Si 8.52%, Mg 0.37%, Fe 0.63%, CR0.043%, Ti 0.04%, Ni 0.030%, BA 0.040%, C 0.006%, B 0.010% The balance is Al and impurity elements, and the monocity of impurity elements is ≤0.05%, and the total amount is ≤0.15%.

[0081] The aluminum alloy is used to regenerate, including the following steps:

[0082] (1) Select waste car motor shell, waste motorcycle wheel, waste ship aluminum plate, waste mobile shell, aluminum nickel carbon alloy, barium barium alloy and aluminum boron alloy as raw materials;

[0083] (2) Waste automotive motor shells that will account for 67% of the total amount of raw materials, 21% of the waste motorcycle hub, 7% used ship aluminum plate and 3.8% waste mobile shell are heated to aluminum alloy fluids at 750 ° C;

[0084] (3) Adding an aluminum nickel carbon alloy having a total amount of raw material, 0.4% aluminum barium alloy, and 0.2% aluminum boron alloy in the aluminum allo...

Embodiment 3

[0090] Aluminum alloy consists of the following mass percentage of ingredients: Si 8.74%, Mg 0.35%, Fe 0.64%, CR0.037%, Ti 0.025%, BA 0.035%, C 0.005%, B 0.007% The balance is Al and impurity elements, and the monocity of impurity elements is ≤0.05%, and the total amount is ≤0.15%.

[0091] The aluminum alloy is used to regenerate, including the following steps:

[0092] (1) Select waste car motor shell, waste motorcycle wheel, waste ship aluminum plate, waste mobile shell, aluminum nickel carbon alloy, barium barium alloy and aluminum boron alloy as raw materials;

[0093] (2) Waste automotive motor shells that will account for 68% of the total amount of raw materials, 22% of used motorcycle hub, 6% used ship aluminum plate and 3% used mobile phone case were heated to aluminum alloy fluids at 745 ° C;

[0094] (3) Adding an aluminum nickel-carbon alloy having a total amount of 0.5% of the total amount of raw material, 0.35% aluminum barium alloy and 0.15% aluminum boron alloy are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com