Full-premixing water-cooling gas burner with dynamically adjustable gas flow channel

A gas burner and air flow channel technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problem of unadjustable gaps in water-cooled burners, reduce the theoretical combustion temperature, stabilize the flame, and increase the excess air coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in further detail below in conjunction with accompanying drawing:

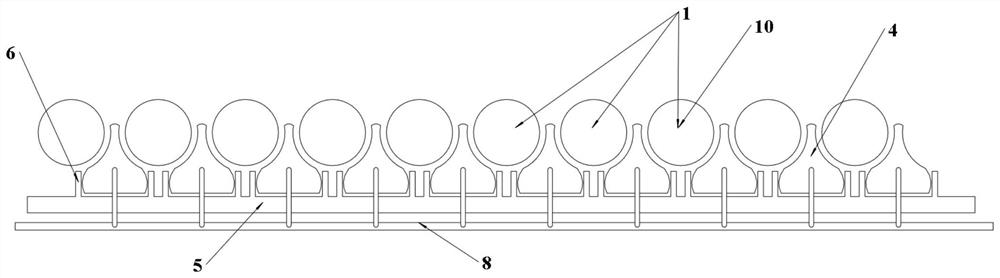

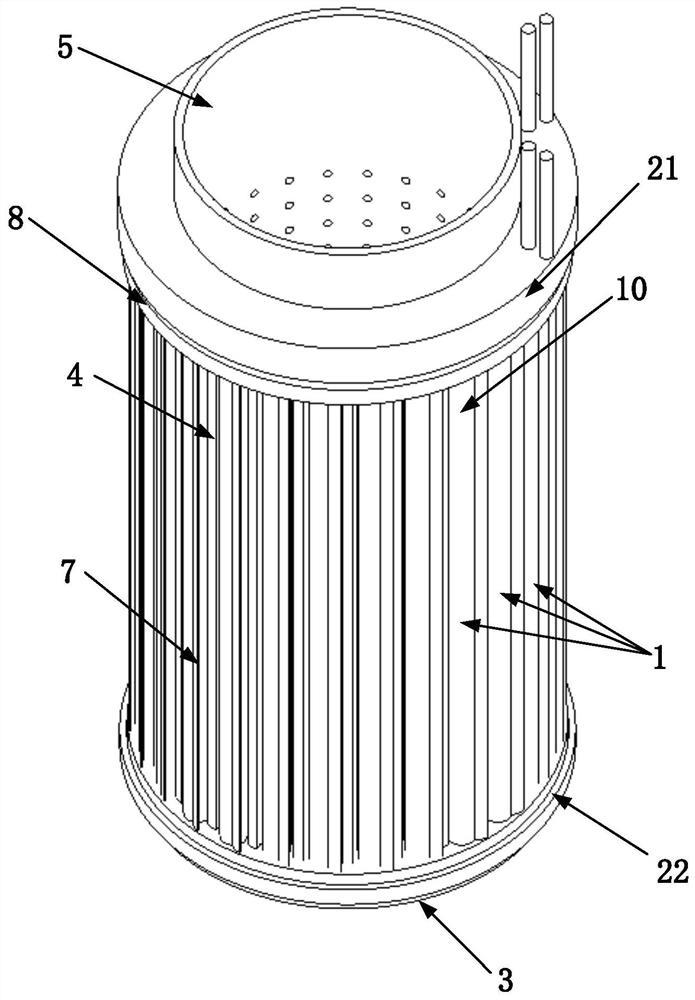

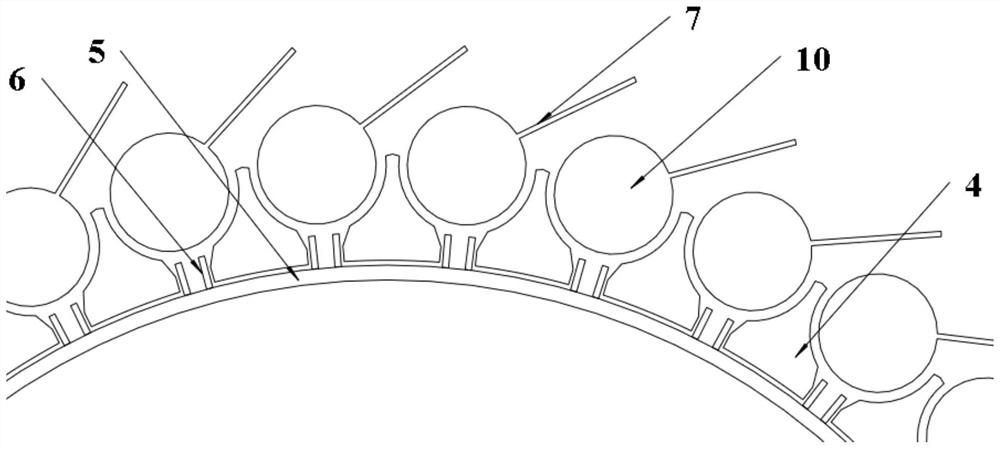

[0037]In order to meet the combustion requirements of premixed gas at different flow rates, make it possible to adjust the gap as large as possible when the speed is high to prevent defiring, and to reduce the gap as much as possible to prevent backfire when the speed is small, a fully premixed water cooling system with adjustable gap is proposed. The combustion head, through a certain adjustment mechanism, adjusts the distance between the deflector adjustment plate and the water-cooled tube bundle, thereby changing the size of the gap and realizing the full combustion of the premixed gas at different flow rates. At the same time, compared with other types of fully premixed gas burners, because the water-cooled tube bundle occupies the flow cross-section of the mixed gas, the flow rate of the mixed gas is high, and the flame size is long, which will inevitably increase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com