Transmission electron microscope electrochemical detection chip and manufacturing method thereof

A transmission electron microscope and detection chip technology, applied in the direction of material electrochemical variables, measuring devices, scientific instruments, etc., can solve the problems of inconvenience, the electrochemical detection chip does not have the temperature detection function, etc., and achieve the effect of electric field stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

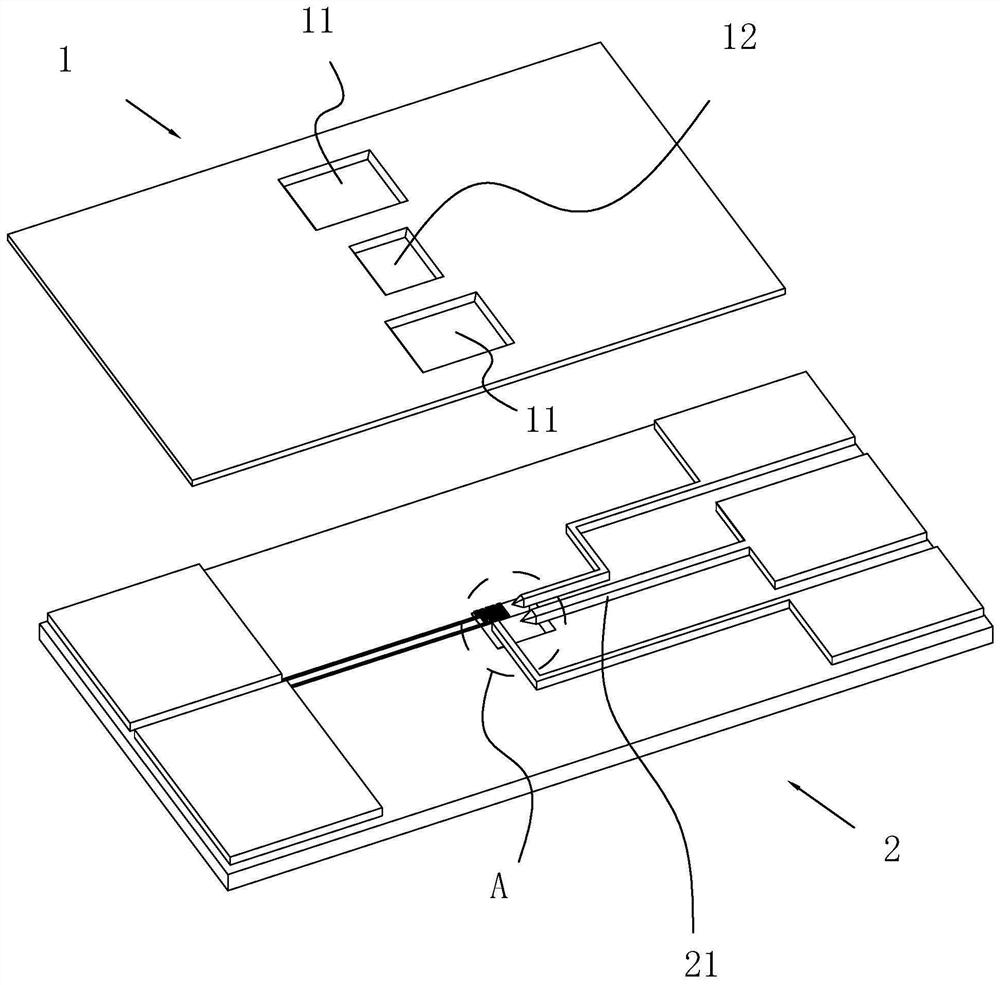

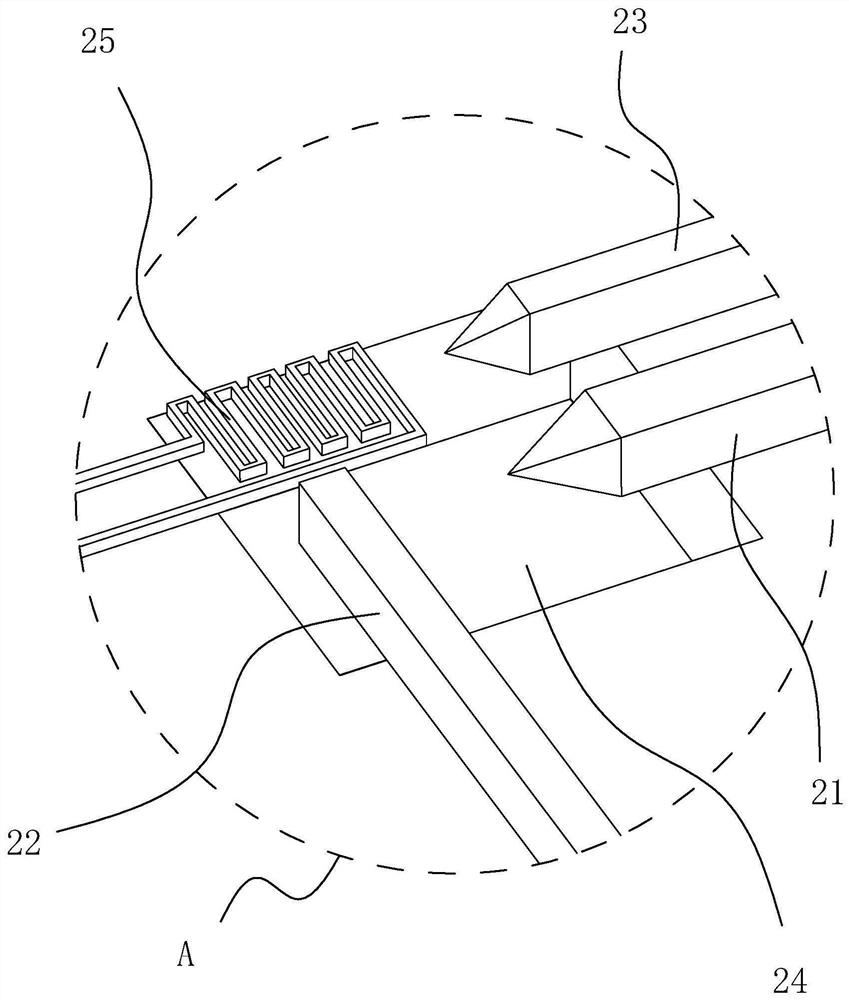

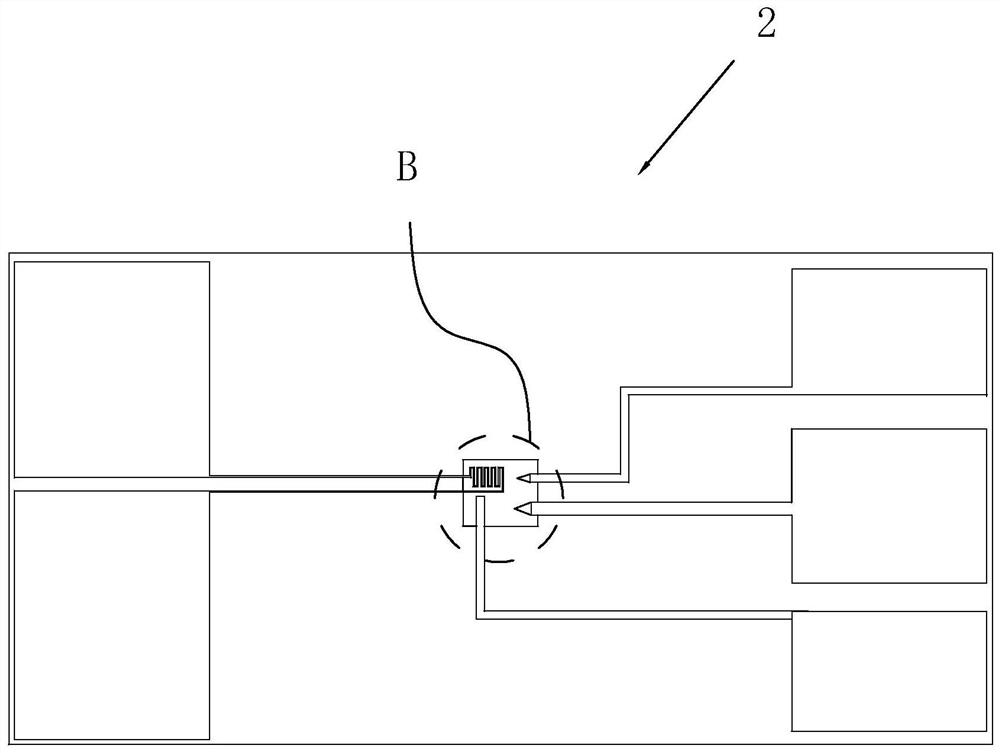

[0047] Such as Figures 1 to 4 As shown, a transmission electron microscope electrochemical detection chip includes an upper chip 1 and a lower chip 2, the upper chip 1 and the lower chip 2 are silicon substrates with insulating layers on the front and back sides.

[0048] Those skilled in the art are familiar with: the general structure of above-mentioned silicon substrate is as follows Figure 5 As shown, it includes a base silicon 31 in the middle, an insulating layer 32 on the front side and an insulating layer 33 on the back side. In this embodiment, the insulating layer is a silicon nitride layer or a silicon oxide layer, which prevents the reaction solution inside the chip from volatilizing and destroying the vacuum environment inside the electron microscope, and at the same time allows the electron beam to pass through to facilitate imaging by the transmission electron microscope. In this embodiment, the thickness of the insulating layer is 5-200 nanometers, and the t...

Embodiment 2

[0061] The difference between this embodiment and the first embodiment is that the TEM electrochemical detection chip also includes a carbon electrode (not shown in the figure), and the carbon electrode covers the working electrode 21 and is not in contact with the counter electrode 23 . The introduction of carbon electrodes can effectively improve imaging resolution and reduce background noise.

[0062] Further, the carbon electrode is composed of a carbon film plated on the working electrode 21, which is convenient for manufacture. In this embodiment, the thickness of the carbon film is 10-80 nanometers.

Embodiment 3

[0064] The present invention also provides a manufacturing method of a transmission electron microscope electrochemical detection chip, which can be used to manufacture the transmission electron microscope electrochemical detection chip described in Embodiment 1.

[0065] Such as Figure 6 As shown, the manufacturing method includes the following steps:

[0066] S1: Process the sample injection port and the first window on the silicon substrate A with insulating layers on both the front and back sides, and manufacture the top wafer.

[0067] S2: Process a working electrode, a reference electrode, a counter electrode, a second window and a thermometer on the silicon substrate B with insulating layers on both the front and back sides, and manufacture the lower film.

[0068] S3: bonding the upper sheet and the lower sheet through an adhesive layer to obtain a transmission electron microscope electrochemical detection chip. The top sheet, bottom sheet, and adhesive layer togeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com