Fresh milk and production process thereof

A production process and fresh milk technology, applied in milking devices, milk preparations, other dairy products, etc., can solve the problems of easy damage and poor stability of active ingredients, achieve the purpose of retaining active ingredients, improving bactericidal effect, optimizing Effect of centrifugation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

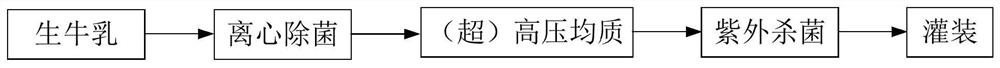

[0046]The present embodiment provides a kind of production technology of fresh milk, as figure 1 shown, including the following steps:

[0047] (1) Selection of raw milk: the number of bacteria in the selected raw milk is ≤100,000 cfu / g, the number of somatic cells is ≤50,000 / g, other requirements meet the national food safety standard "Raw Milk" of GB19301, and the raw milk is stored at 4°C refrigeration;

[0048] (2) Centrifugal sterilization: After the raw milk is cleaned by a milk cleaner, it is sterilized by a centrifugal sterilizer with a centrifugal speed of 5000r / min and a centrifugal temperature of 40°C. The milk cleaning here is a conventional pretreatment process, which refers to the removal of Mechanical impurities, dust, cell debris, etc. in the product effectively control the cleanliness of milk. The milk cleaning is carried out in the milk cleaning machine;

[0049] (3) Homogenization of raw milk: The raw milk after centrifugal sterilization is homogenized by ...

Embodiment 2

[0052] The present embodiment provides a kind of production technology of fresh milk, as figure 1 shown, including the following steps:

[0053] (1) Selection of raw milk: the number of bacteria in the selected raw milk is ≤100,000 cfu / g, the number of somatic cells is ≤50,000 / g, other requirements meet the national food safety standard "Raw Milk" of GB19301, and the raw milk is stored at 4°C refrigeration;

[0054] (2) Centrifugal sterilization: After the raw milk is cleaned by a milk cleaner, it is sterilized by a centrifugal sterilizer, with a centrifugal speed of 3000r / min and a centrifugal temperature of 2°C. The milk cleaning here is a conventional pretreatment process, which refers to the removal of bacteria. Mechanical impurities, dust, cell debris, etc. in the product effectively control the cleanliness of milk. The milk cleaning is carried out in the milk cleaning machine;

[0055] (3) Homogenization of raw milk: The raw milk after centrifugal sterilization is homo...

Embodiment 3

[0058] The present embodiment provides a kind of production technology of fresh milk, as figure 1 shown, including the following steps:

[0059] (1) Selection of raw milk: the number of bacteria in the selected raw milk is ≤100,000 cfu / g, the number of somatic cells is ≤50,000 / g, other requirements meet the national food safety standard "Raw Milk" of GB19301, and the raw milk is stored at 4°C refrigeration;

[0060] (2) Centrifugal sterilization: After the raw milk is cleaned by a milk cleaner, it is sterilized by a centrifugal sterilizer with a centrifugal speed of 6000r / min and a centrifugal temperature of 65°C. The milk cleaning here is a conventional pretreatment process, which refers to the removal of bacteria. Mechanical impurities, dust, cell debris, etc. in the product effectively control the cleanliness of milk. The milk cleaning is carried out in the milk cleaning machine;

[0061] (3) Homogenization of raw milk: The raw milk after centrifugal sterilization is homo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com