Microfluidic paper chip, preparation method thereof, microfluidic paper chip detection system and application

A microfluidic paper chip, paper chip technology, applied in fluid controllers, chemical instruments and methods, measurement devices, etc., can solve problems such as non-specific adsorption, contamination of samples, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

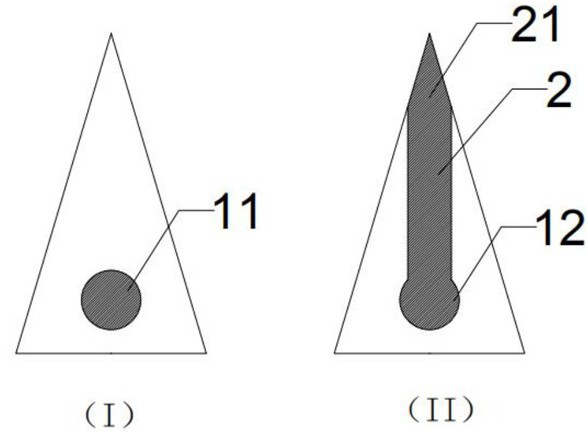

[0073] A microfluidic paper chip, such as figure 1As shown, (I) is the front view of the microfluidic paper chip, (II) is the back view of the microfluidic paper chip; The back view of the paper chip includes a detection area 2 , a filtrate area 12 and a sampling port 21 in the detection area. The sample injection area 11, the filtrate area 12 and the detection area 2 of the microfluidic paper chip are all located in the hydrophilic area, and the other non-shaded areas are hydrophobic areas. The sample injection area 11 and the filtrate area 12 of the microfluidic paper chip are located at corresponding positions on both sides of the microfluidic paper chip. The sample injection area 11 is located at one end of the microfluidic paper chip, and the detection area 2 is strip-shaped and connected to the filtrate area 12 . The sampling area 11 of the microfluidic paper chip is covered with a sulfonic acid-based resin.

Embodiment 2

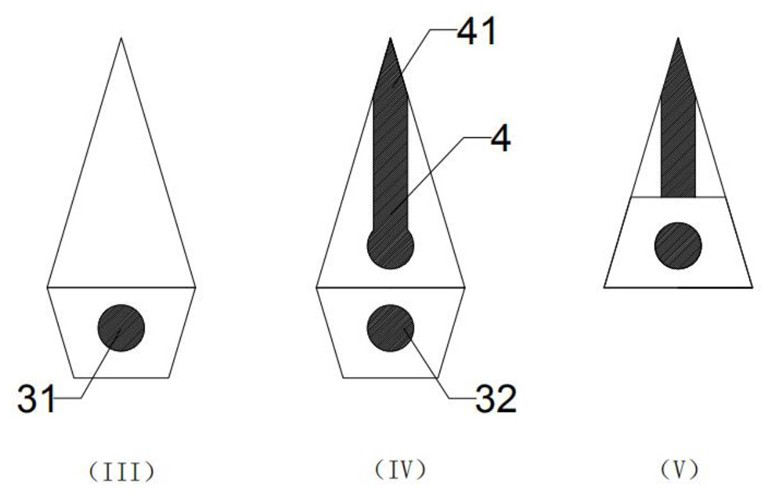

[0075] A microfluidic paper chip, such as figure 2 As shown, (III) is the front view of the microfluidic paper chip, (IV) is the back view of the microfluidic paper chip, (V) is the schematic diagram of the folded microfluidic paper chip, and the front view of the microfluidic paper chip The figure includes the sampling area 31, and the back view of the microfluidic paper chip includes the detection area 4, the filtrate area 32 and the detection area sampling port 41, and the sampling area, the detection area and the filtrate area are all located on the hydrophilic surface of the microfluidic paper chip. area, and other non-shaded areas are hydrophobic areas. The sample injection area 31 and the filtrate area 32 of the microfluidic paper chip are located at corresponding positions on both sides of the microfluidic paper chip. The position of the filtrate area 32 is separated from the detection area 4 before folding. After folding, the filtrate area 32 covers the part of the ...

Embodiment 3

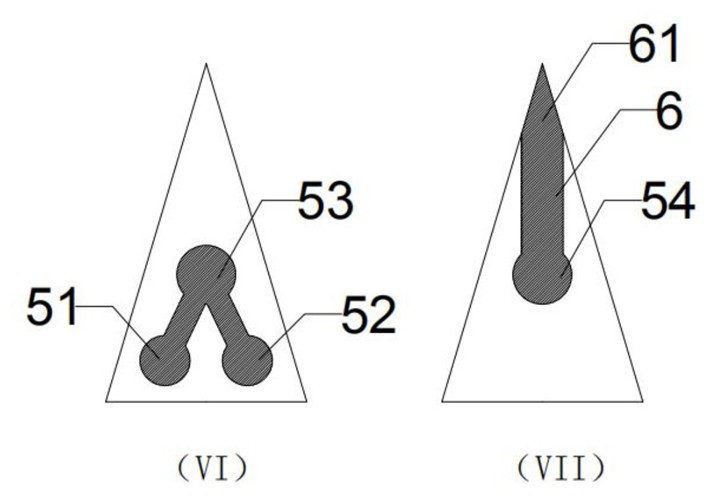

[0077] A microfluidic paper chip, such as image 3 As shown, (VI) is the front view of the microfluidic paper chip, and (VII) is the back view of the microfluidic paper chip. Sample zone reaction zone 53 and the first sampling zone sampling point 51, the second sampling zone sampling point 52, the first sampling zone sampling point 51 and the second sampling zone sampling point 52 pass through the hydrophilic zone channel Connected to the reaction zone 53 of the sample introduction area; the sample introduction area is covered with sulfonic acid-based resin. The back view of the microfluidic paper chip includes a detection area 6, a filtrate area 54, and a sampling port 61 in the detection area. The sampling area, the filtrate area, and the detection area of the microfluidic paper chip are all located in the hydrophilic area on the paper base. The other unshaded regions of the base are hydrophobic regions. The sample injection area reaction area 53 and the filtrate area 54...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com