Thermal management energy-saving control system for battery of pure electric vehicle

An energy-saving control system and battery thermal management technology, applied in electric vehicles, battery/fuel cell control devices, vehicle energy storage, etc., can solve the problems of poor economy, high cost, and high cost of use, so as to avoid heat loss and ensure discharge Activity, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

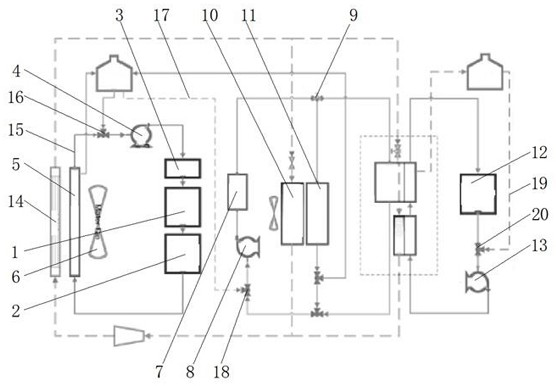

[0021] according to figure 1 As shown, this embodiment proposes a battery thermal management and energy-saving control system for pure electric vehicles, including a thermal management system, a cold-start working condition strategy module, a driving working condition strategy module, and a stable working condition strategy module. Condition strategy module, driving condition strategy module and stable working condition strategy module are used to formulate thermal management control strategies under different working conditions, and the thermal management system is used to execute cold start working condition strategy module, driving condition strategy module and The thermal managem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com