Compound rubidium boron nitrate and rubidium boron nitrate nonlinear optical crystal and preparation method and use

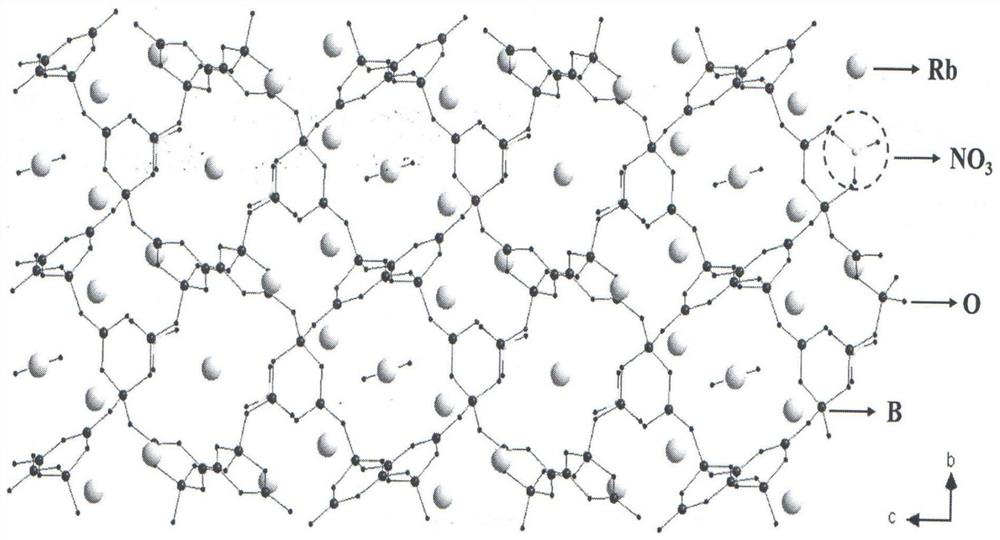

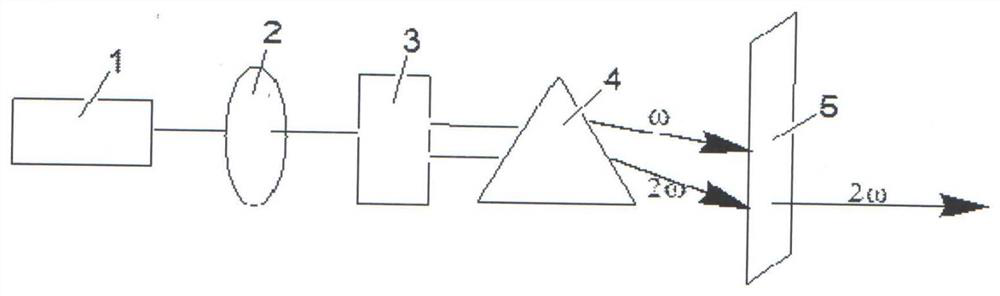

A technology of nonlinear optics and compounds, applied in the direction of nonlinear optics, chemical instruments and methods, boron compounds, etc., can solve problems such as the application of nonlinear optics crystals, the narrowing of the light transmission range, etc., and achieve good optical properties and novel structures characteristic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparing Compounds:

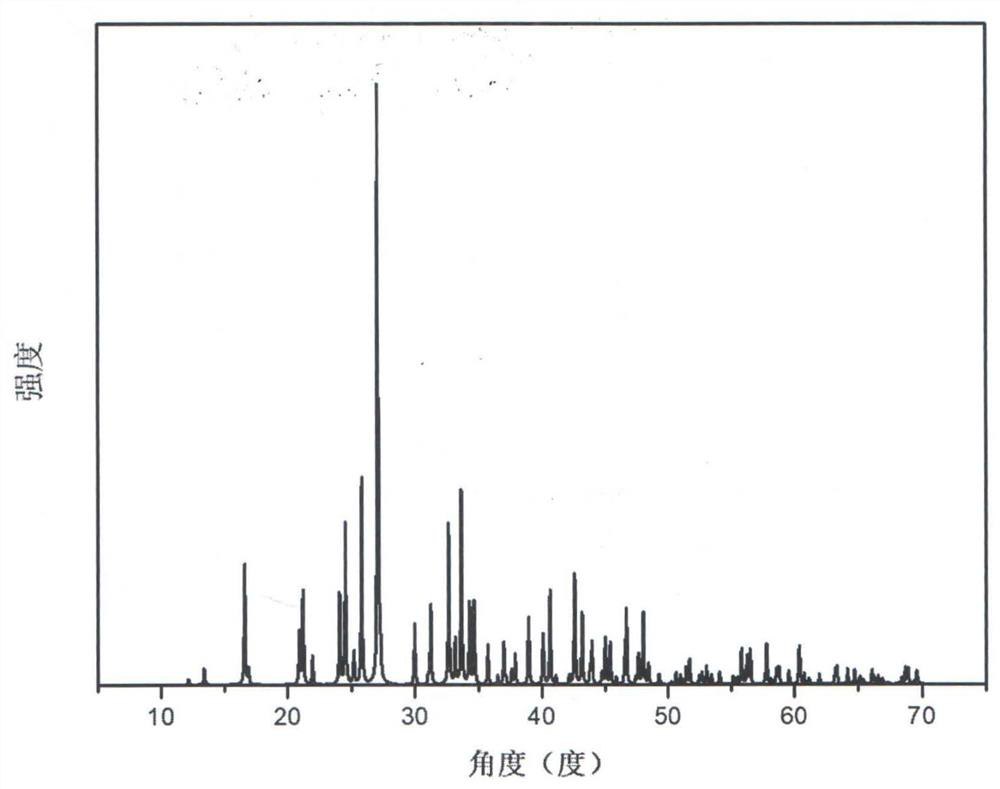

[0040] According to the reaction formula: 6RbF+20H 3 BO 3 +3RbNO 3 →3Rb 3 B 6 O 10 NO 3 +2BF 3 ↑+30H 2 O↑, the compound Rb was synthesized by solid-phase reaction method 3 B 6 O 10 NO 3 :

[0041] a. The RbF, H 3 BO 3 and RbNO 3 Mix evenly at a molar ratio of 6:20:3, put it into a ceramic crucible, place it in a muffle furnace and heat up to 235°C, keep the temperature constant for 10 hours, take out and grind 3 times during the heat preservation period to mix the reactants evenly to generate a powder with uniform components;

[0042] b, put the powder obtained in step a into a ceramic crucible and put it into a muffle furnace, heat up to 340 ° C, and keep the constant temperature for 24 hours to obtain compound Rb 3 B 6 O 10 NO 3 .

Embodiment 2

[0044] Preparing Compounds:

[0045] According to the reaction formula: 6RbF+10B 2 O 3 +3RbNO 3 →3Rb 3 B 6 O 10 NO3+2BF 3 ↑, Compound Rb was synthesized by solid-phase reaction method 3 B 6 O 10 NO 3 :

[0046] a, the RbF, B 2 O 3 and RbNO 3 Mix evenly at a molar ratio of 6:10:3, put it into a ceramic crucible, place it in a muffle furnace and heat up to 230°C, keep the temperature constant for 15 hours, take out and grind 3 times during the heat preservation period to mix the reactants uniformly to generate a powder with uniform components;

[0047] b. Put the powder obtained in step a into a ceramic crucible and put it into a muffle furnace, heat up to 400°C, and keep the temperature constant for 30 hours to obtain compound Rb 3 B 6 O 10 NO 3 .

Embodiment 3

[0049] Preparing Compounds:

[0050] According to the reaction formula: 2RbOH+6H 3 BO 3 +RbNO 3 →Rb 3 B 6 O 10 NO 3 +10H 2 O↑, the compound Rb was synthesized by solid-phase reaction method 3 B 6 O 10 NO 3 :

[0051] a, RbOH, H 3 BO 3 and RbNO 3 Mix evenly at a molar ratio of 2:6:1, put it into a ceramic crucible, place it in a muffle furnace and heat up to 250°C, keep the temperature constant for 20 hours, take out and grind 3 times during the heat preservation period to mix the reactants evenly to generate a powder with uniform components;

[0052]b. Put the powder obtained in step a into a ceramic crucible and put it into a muffle furnace, heat up to 420°C, and keep the constant temperature for 40 hours to obtain compound Rb 3 B 6 O 10 NO 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com