Gypsum powder production system and production process thereof

A production system and production process technology, applied in the field of building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

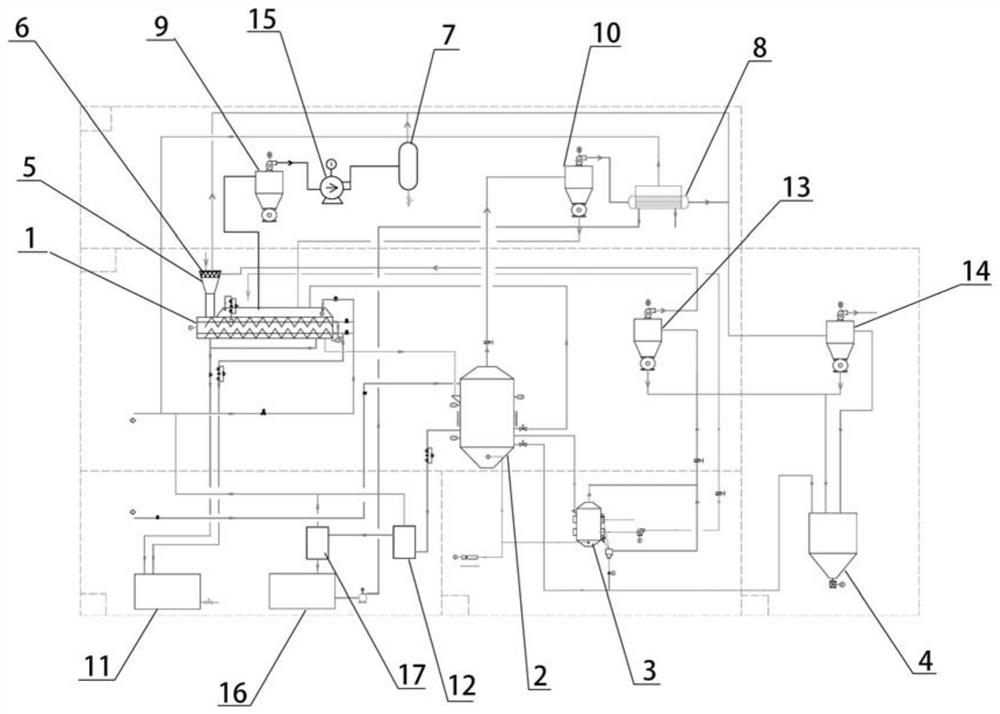

[0035] Such as figure 1 A gypsum powder production system shown includes a paddle dryer 1, a fluidized calciner 2, a vertical cooler 3, and a finished product bin 4. After the gypsum is first dried by the paddle dryer 1, it enters the fluid flow calcined in the calciner 2, then enters the vertical cooler 3 for cooling, and finally enters the finished product bin 4 after being pressed;

[0036] A feeding hopper 5 is installed at the feeding port of the fluidized calciner 2, and a grid heat exchanger 6 is installed in the feeding hopper 5, and the grid heat exchanger 6 passes through the vertical cooler 3 pipe connection;

[0037] The production system also includes a flash separator 7 and a calcining steam heat exchanger 8, the flash separator 7 is connected to the paddle dryer 1, the calcining steam heat exchanger 8 is connected to the fluidized calcining The machine 2 is connected; the secondary steam generated during the calcination process of the material in the fluidized...

Embodiment 2

[0048] A kind of gypsum powder production process, described production process adopts the production system described in embodiment 1, and described production process comprises the steps:

[0049] When the gypsum enters the feeding hopper 5, it is preheated by the grid heat exchanger 6, and then enters the paddle dryer 1 for drying; the condensed water generated in the paddle dryer 1 enters the In the drier condensate tank 11 of the production system;

[0050] The dried gypsum enters the fluidized calciner 2 for calcining, and the secondary steam generated during the calcining process of the material in the fluidized calciner 2 returns to the The paddle dryer 1 provides a supplementary drying heat source for the material. In order to make full use of the heat energy, a vacuum pump is used to evacuate the paddle dryer 1 with a vacuum degree of -20Kpa, and the paddle dryer 1 is vacuumed by the flash separator. The material in the inner chamber of the leaf dryer is flashed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com