Exhaust system of vehicle

An exhaust system and vehicle technology, applied in the direction of exhaust treatment, exhaust device, electronic control of exhaust treatment device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

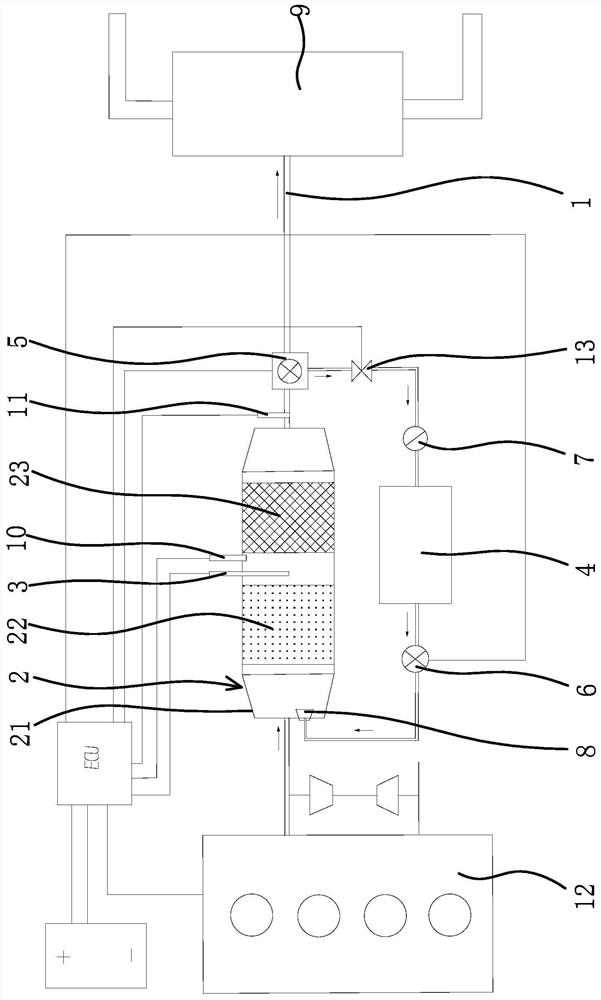

[0027] like figure 1 As shown, this embodiment includes an exhaust pipe 1, a gas storage element 4, an electric control 5, and a catalytic converter 2 arranged on the exhaust pipe 1 and connected between the inlet and the outlet of the exhaust pipe 1, and the inlet of the exhaust pipe 1 Used to communicate with the outlet of the engine 12 , and the outlet of the exhaust pipe 1 is used to communicate with the muffler 9 . The catalytic converter 2 is provided with a temperature sensor 3 for detecting the gas temperature. The gas storage part 4 is a gas storage tank or a gas storage box, and the inlet and outlet of the gas storage part 4 communicate with the outlet and the inlet of the catalytic converter 2 respectively through pipes. The electric control 5 is located at the intersection of the pipe between the outlet of the catalytic converter 2 and the inlet of the gas storage part 4 and the exhaust pipe 1. The electric control 5 is a three-way solenoid valve with an inlet, an...

Embodiment 2

[0034] The technical solution of this embodiment is basically the same as the technical solution of Embodiment 1, the difference being that the electric control 5 in this embodiment includes solenoid valve 1 and solenoid valve 2 both having an inlet and an outlet, and solenoid valve 1 is set On the exhaust pipe 1 and between the outlet of the catalytic converter 2 and the outlet of the exhaust pipe 1 , the solenoid valve 2 is arranged on the pipeline between the outlet of the catalytic converter 2 and the inlet of the gas storage element 4 . The pipeline between the outlet of electromagnetic valve two and the inlet of air storage part 4 is provided with air pump one 13 and check valve 7, and the inlet of air pump one 13 is communicated with the outlet of electromagnetic valve two, and the outlet of air pump one 13 is connected with check valve. The inlet of 7 communicates, and the outlet of one-way valve 7 communicates with the inlet of gas storage element 4 .

[0035] The ele...

Embodiment 3

[0037] The technical solution of the present embodiment is basically the same as that of the first embodiment, the difference is that the present embodiment is not provided with an air pump two on the pipeline between the outlet of the gas storage part 4 and the inlet of the catalytic converter 2, but on the A pressure sensor 3 is arranged inside the gas storage part 4 to ensure that the exhaust gas in the gas storage part 4 flows to the catalytic converter 2 when the electric control valve 6 is opened. When the temperature sensor 3 detects that the gas temperature in the catalytic converter 2 is below the set value, the ECU controls the electric control 5 to connect the outlet of the catalytic converter 2 with the inlet of the gas storage part 4 and disconnect the outlet of the catalytic converter 2 and the outlet of the exhaust pipe 1, and at the same time Control air pump one 13 to open and electric control valve 6 to close, so that the exhaust gas pretreated by catalytic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com