Fault current suppression method and system for double-electrical-port variable- flux motor, and medium

A technology of fault current and variable magnetic flux, applied in the control system, current controller, AC motor control and other directions, can solve the problem of reducing the effect of fault current, excessive short-circuit current, high back electromotive force of permanent magnet synchronous machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

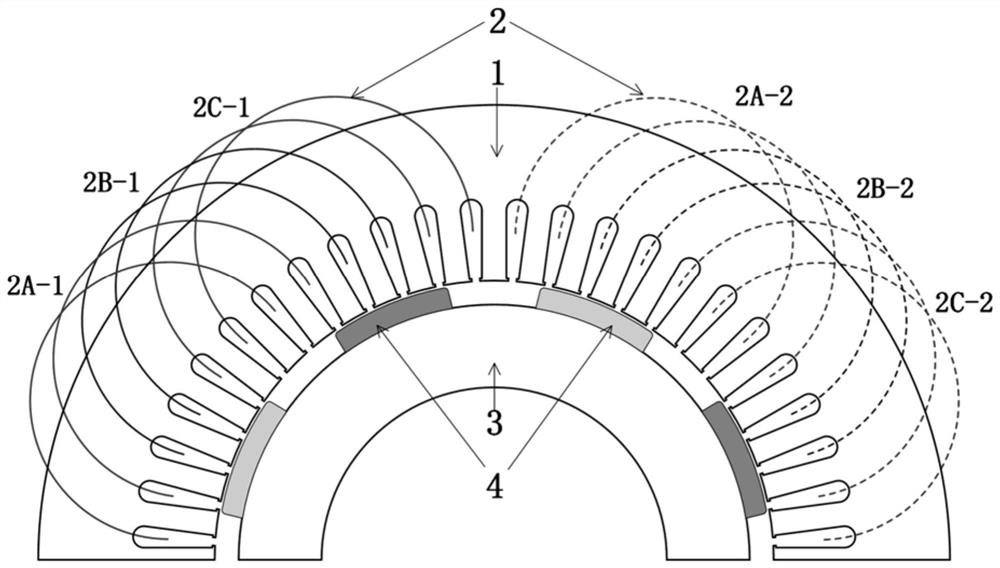

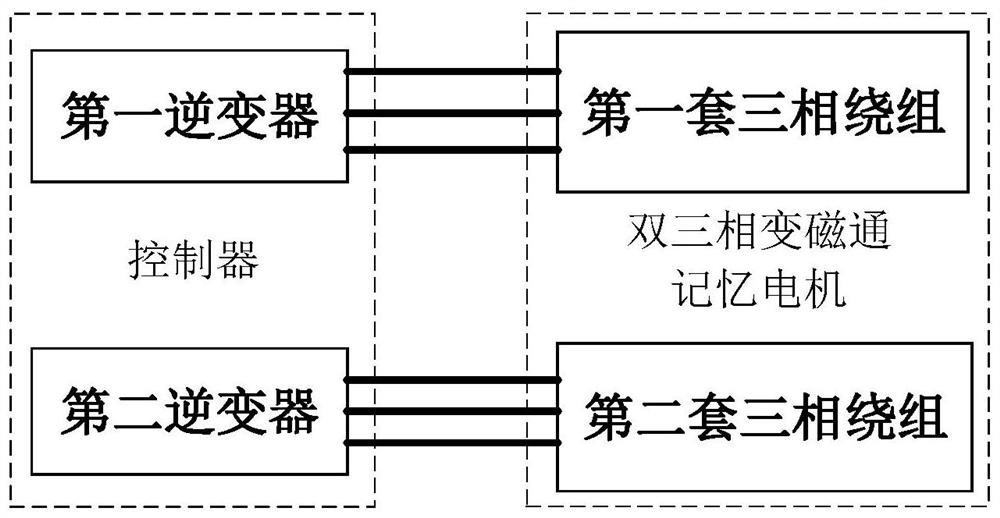

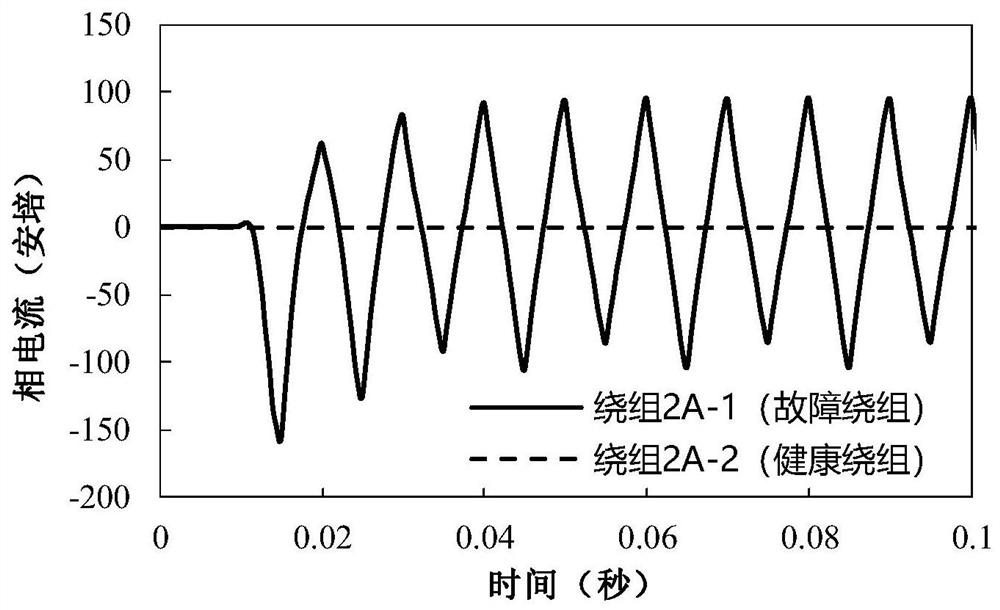

[0040] refer to figure 1, The double-winding variable flux memory motor has a stator with 48 slots and a rotor with 8 poles. It includes a stator core 1, a stator armature winding 2, a rotor core 3, and a demagnetizable permanent magnet 4. The rotor core 3 is located at the bottom of the stator core 1. internal. Both the stator core 1 and the rotor core 3 can be made of laminated silicon steel sheets; the stator armature winding 2 is placed on the stator core 1 , and the demagnetizable permanent magnet 4 is placed on the rotor core 3 . In this embodiment, the stator armature winding 2 is a double three-phase AC winding, that is, two sets of three-phase armature windings, and a total of twenty-four armature coils are formed, that is, each set of three-phase armature windings includes twelve armature windings. Armature coil, wherein each phase armature winding includes four armature coils, specifically, the first armature winding includes 2A-1 phase, 2B-1 phase, 2C-1 phase; the...

Embodiment 2

[0047] The variable flux memory motor system, the main structure of the motor includes a stator core 1, a variable flux permanent magnet placed on the stator core 1; an AC armature winding placed on the stator core 1; a DC pulse current winding placed on the stator core 1; Rotor core 3. When the motor is running normally, the armature winding is loaded with a periodic sinusoidal current, and a stable torque is output to complete the electromechanical energy conversion. At this time, the DC pulse current winding does not work. When a short-circuit fault occurs in the AC armature winding of the motor or the corresponding three-phase inverter fails, a demagnetizing DC current pulse is actively loaded on the dedicated DC pulse current winding to weaken the magnetic field strength of the demagnetizable permanent magnet, thereby reducing the electric current. The magnitude of the counter electromotive force and the magnitude of the short-circuit current induced on the pivot winding....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com