Fully-sealed goggles

A goggles, fully-sealed technology, applied in the field of glasses, can solve the problems of inability to discharge goggles moisture in time, poor air permeability, etc., and achieve the effect of preventing irritating gases from entering the eyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

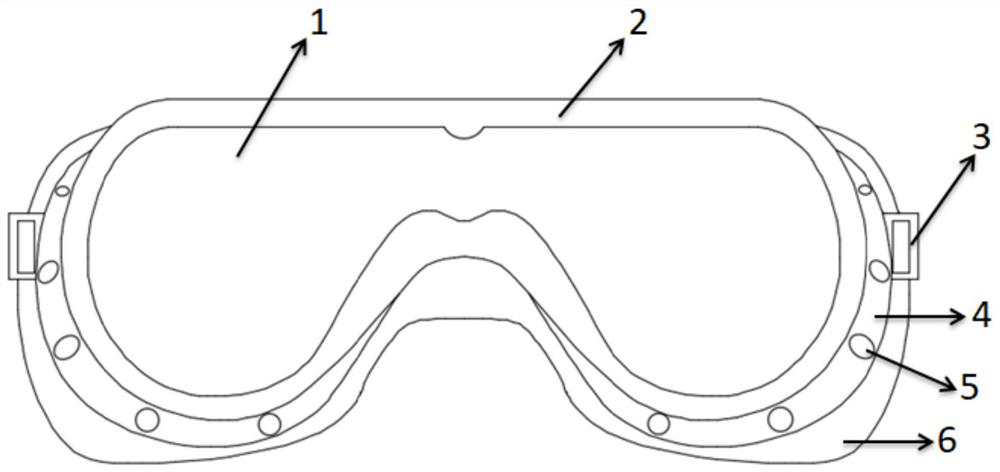

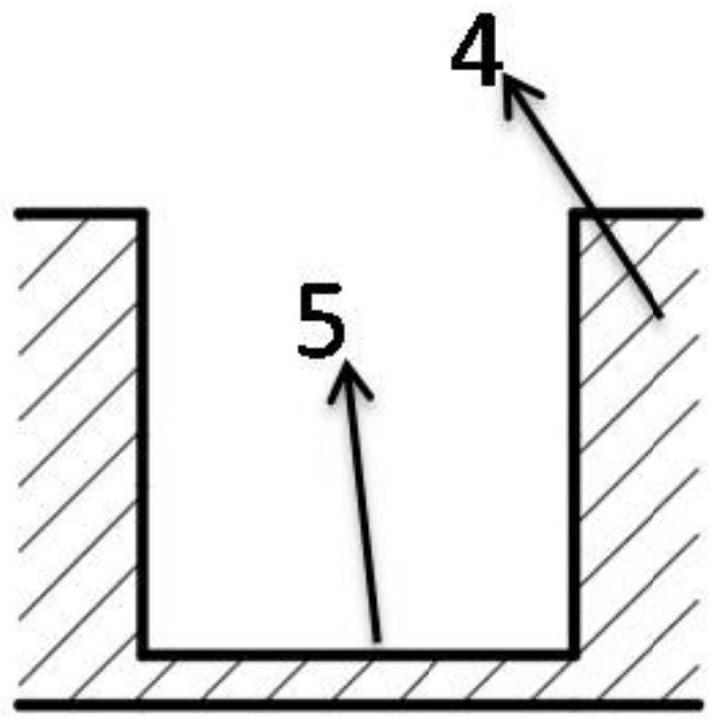

[0045] Such as figure 1 As shown, a fully sealed goggle is made of a colorless and transparent engineering plastic polycarbonate lens 1, a frame made of silicone rubber with a Shore A hardness of 50, and a frame made of silicone rubber with a Shore A hardness of 50. 50 silicone rubber, the frame 4 connected to the mirror frame and the sealing element 6 in contact with the wearer's face constitute. In the goggles, the silicone rubber material of the frame 2 and the polycarbonate material of the lens 1 are bonded by a heat vulcanization molding process. On the silicone rubber frame 4, there are 10 circular silicone rubber films with a diameter between 5.0mm and 7.5mm and a thickness between 0.03mm and 0.05mm, such as figure 2 As shown, the silicone rubber film is located on the inner surface of the goggles frame 4 (that is, the side close to the face when worn), and there are two bayonets 3 made of silicone rubber material for installing straps on the frame 4;

[0046] The po...

Embodiment 2

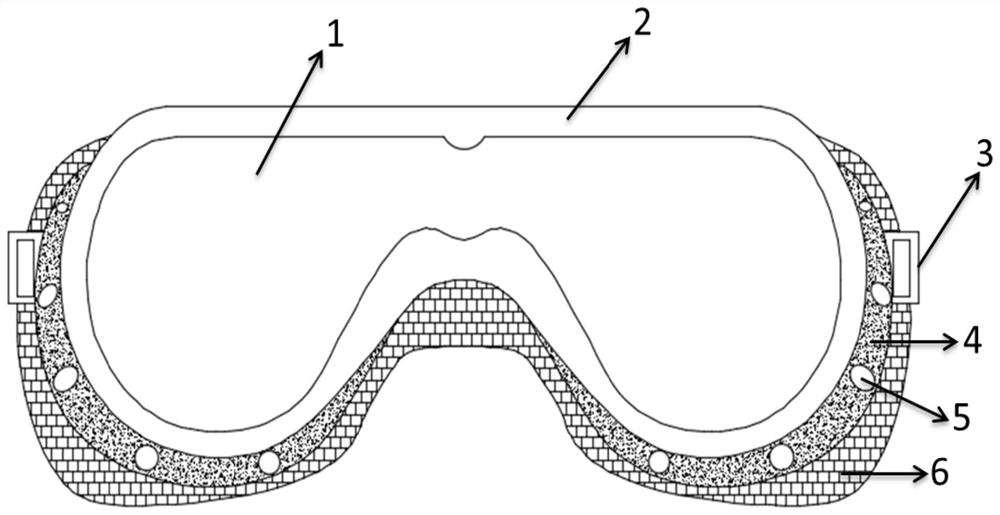

[0060] Such as image 3 As shown, a fully sealed goggles are made of a lens 1 made of engineering plastic polycarbonate, a frame 2 made of silicon rubber, a frame 4 connected to the frame, and a sealing element 6 that is in contact with the human face. There are 10 moisture-permeable structures on the silicone rubber frame 4. The moisture-permeable structure is a circular silicone rubber film with a diameter of 2.5-5mm and a thickness of 0.1mm. The frame 4 is made of two silicone rubber materials for installation. The strap bayonet 3 of the strap. Such as Figure 4 As shown, the silicone rubber film is located on the outer surface of the goggle frame 4 (ie the side away from the face when worn).

[0061] Among them, the Shore A hardness of the silicone rubber used in the frame 6 that is in contact with the human face is 10±2, and the silicone rubber Shore A hardness of the frame 2, the frame 4 connected to the frame, the moisture-permeable structure 5, and the strap bayonet ...

Embodiment 3

[0064] Such as Figure 5As shown, a fully sealed goggles are made of a lens 1 made of engineering plastic polycarbonate, a frame 2 made of silicon rubber, a frame 4 connected to the frame, and a sealing element 6 that is in contact with the human face. There are 10 moisture-permeable structures on the silicone rubber frame 4. The moisture-permeable structure is a diamond-shaped silicone rubber film with a thickness of 0.1mm. The frame 4 has two strap bayonets made of silicone rubber for installing straps. 3. Such as Figure 6 As shown, the silicone rubber film is located in the middle of the goggle frame 4 .

[0065] Among them, the Shore A hardness of the silicone rubber used in the frame 6 that is in contact with the human face is 10±2, and the silicone rubber Shore A hardness of the frame 2, the frame 4 connected to the frame, the moisture-permeable structure 5, and the strap bayonet 3 A hardness is 60±2.

[0066] In this embodiment, the polycarbonate lens 1 and the sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com