Easy demolding treatment method for inner surface of casting mold

A technology for casting molds and treatment methods, which is applied in the field of easy-release treatment of the inner surface of casting molds, can solve the problems of release agent falling off, spraying dead angles, casting damage, etc., and achieve the goals of promoting effective penetration, improving demoulding effect, and accelerating separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

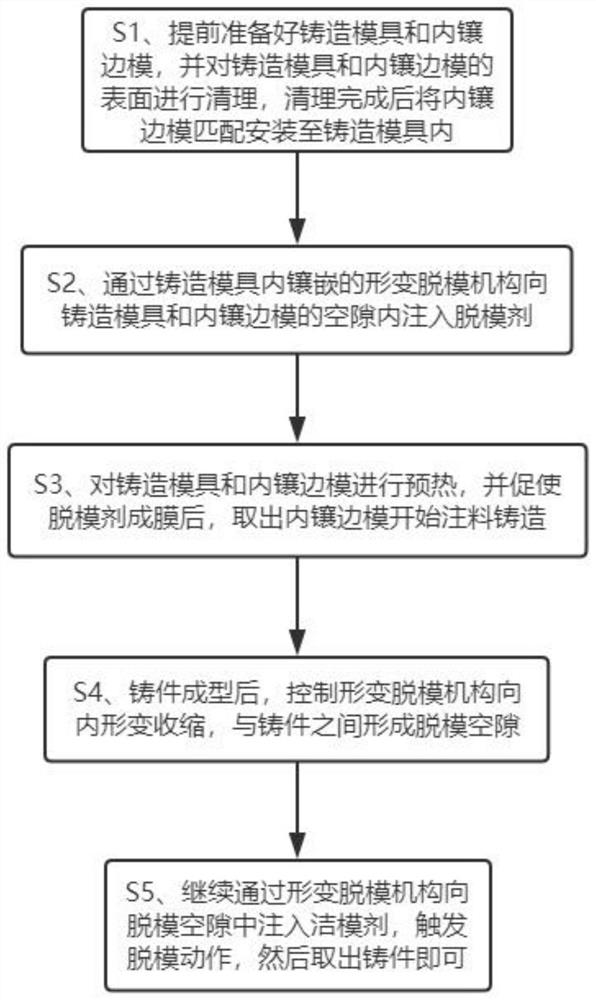

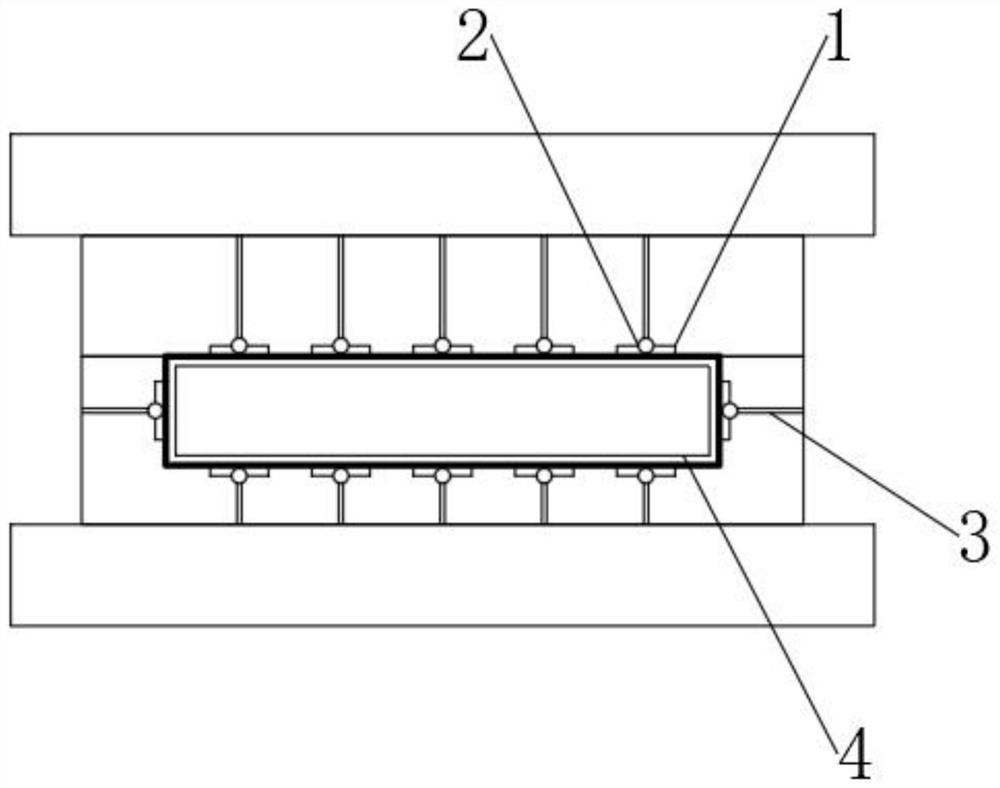

[0045] see figure 1 , a casting mold inner surface easy demoulding treatment method, comprising the following steps:

[0046] S1. Prepare the casting mold and the inner trimming mold 4 in advance, and clean the surfaces of the casting mold and the inner trimming mold 4. After the cleaning is completed, the inner trimming mold 4 is matched and installed in the casting mold;

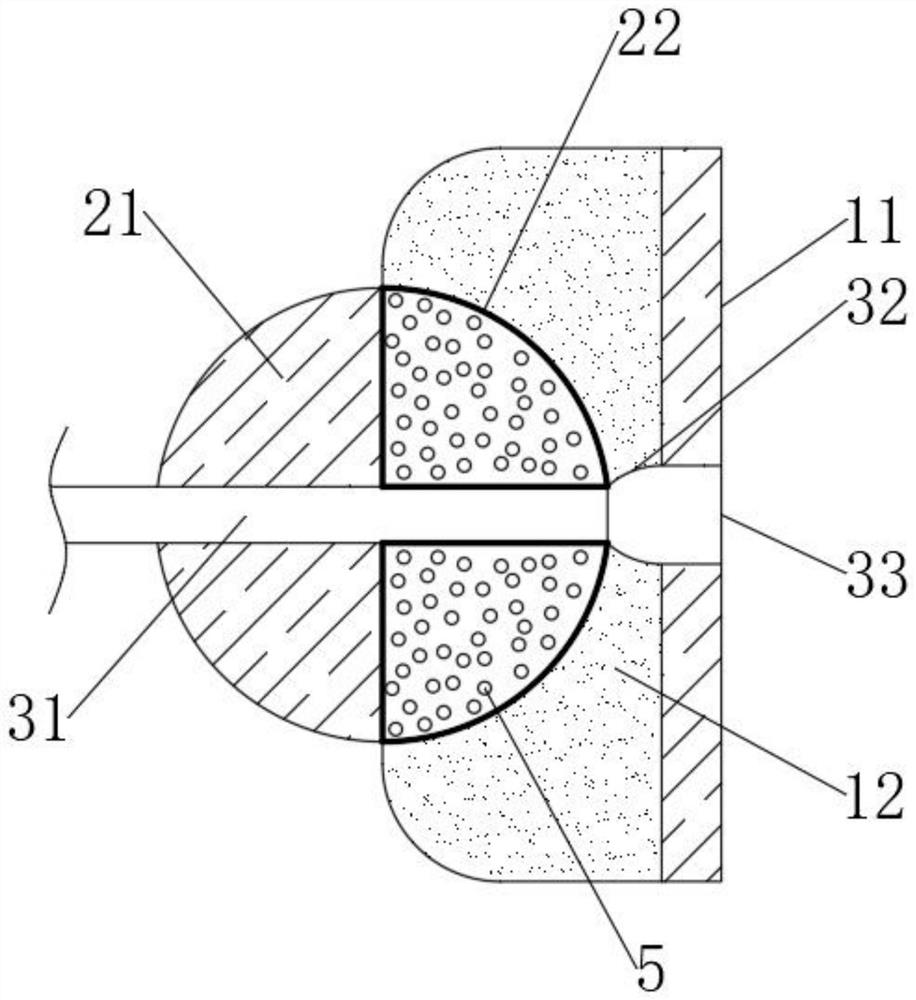

[0047] S2. Inject a release agent into the gap between the casting mold and the inner trimming mold 4 through the deformation demoulding mechanism embedded in the casting mold;

[0048] S3. Preheating the casting mold and the inner edging mold 4, and promoting the release agent to form a film, taking out the inner edging mold 4 and starting injection casting;

[0049] S4. After the casting is formed, the deformation and demoulding mechanism is controlled to deform and shrink inwardly, forming a demoulding gap with the casting;

[0050] S5. Continue to inject the mold cleaner into the demoulding gap throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com