Preparation method of anti-crack, self-healing and root-resistant functional additive for concrete

A concrete and functional technology, applied in the field of building materials, can solve problems such as waste of resources, and achieve the effects of improving service life, increasing volume stability, and increasing osmotic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

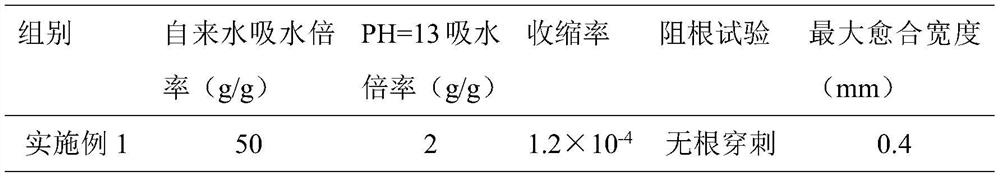

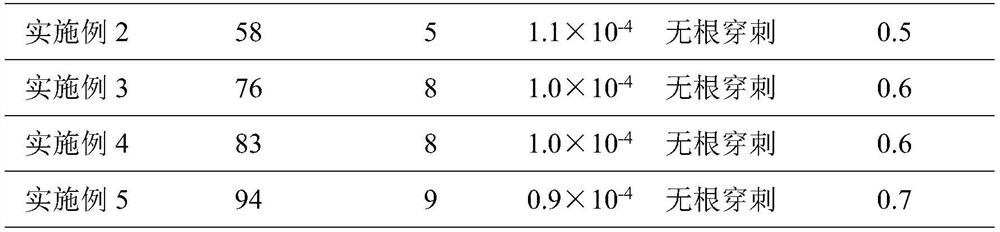

Examples

Embodiment 1

[0021] 1) 100 parts by mass of copper tailings, 500 parts by mass of water and 1 part by mass of grinding aid are mixed and placed in a wet mill at a speed of 400 RPS to wet grind to a median particle size of 100nm to obtain nanometer copper tailings;

[0022] 2) Get 50 parts by mass of 2% (g / mL) chitosan solution and put it into an electromagnetic stirrer with a rotating speed of 300r / min, add 10 parts by mass of 0.25mol / L glutaraldehyde solution during stirring, Stir in a constant temperature water bath for 10 minutes;

[0023] 3) Add 5 parts by mass of the nano-copper tailings in step 1) to the solution in step 2) and continue the constant temperature water bath for 1 hour, freeze-dry for 24 hours to obtain the anti-cracking-self-healing-root-blocking functional additive for concrete.

Embodiment 2

[0025] 1) 100 parts by mass of copper tailings, 480 parts by mass of water and 1.2 parts by mass of grinding aid are mixed and placed in a wet mill at a speed of 420RPS to wet grind to a median particle size of 85nm to obtain nanometer copper tailings;

[0026] 2) Get 50 parts by mass of 2.2% (g / mL) chitosan solution and put it into an electromagnetic stirrer with a rotating speed of 300r / min, add 10 parts by mass of 0.28mol / L glutaraldehyde solution during stirring, Stir in a constant temperature water bath for 10 minutes;

[0027] 3) Add 6 parts by mass of the nano-copper tailings in step 1) to the solution in step 2) and continue the constant temperature water bath for 1 hour, freeze-dry for 24 hours to obtain the anti-cracking-self-healing-root-blocking functional additive for concrete.

Embodiment 3

[0029] 1) 100 parts by mass of copper tailings, 450 parts by mass of water and 1.4 parts by mass of grinding aid are mixed and placed in a wet mill at a speed of 430 RPS to wet grind to a median particle size of 70nm to obtain nano copper tailings;

[0030] 2) Get 50 parts by mass of 2.5% (g / mL) chitosan solution and put it into a 300r / min electromagnetic stirrer, add 10 parts by mass of 0.3mol / L glutaraldehyde solution during stirring, Stir in a constant temperature water bath for 10 minutes;

[0031] 3) Add 8 parts by mass of the nano-copper tailings in step 1) to the solution in step 2) and continue the constant temperature water bath for 1 hour, freeze-dry for 24 hours to obtain the anti-cracking-self-healing-root-blocking functional additive for concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com