Dye liquor for producing high-color-fastness yarn and water-saving spray dyeing process thereof

A high color fastness, yarn technology, applied in the field of yarn dyeing, can solve the problem of a lot of consumption, achieve the effect of good color fastness, reduce washing times, and improve color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

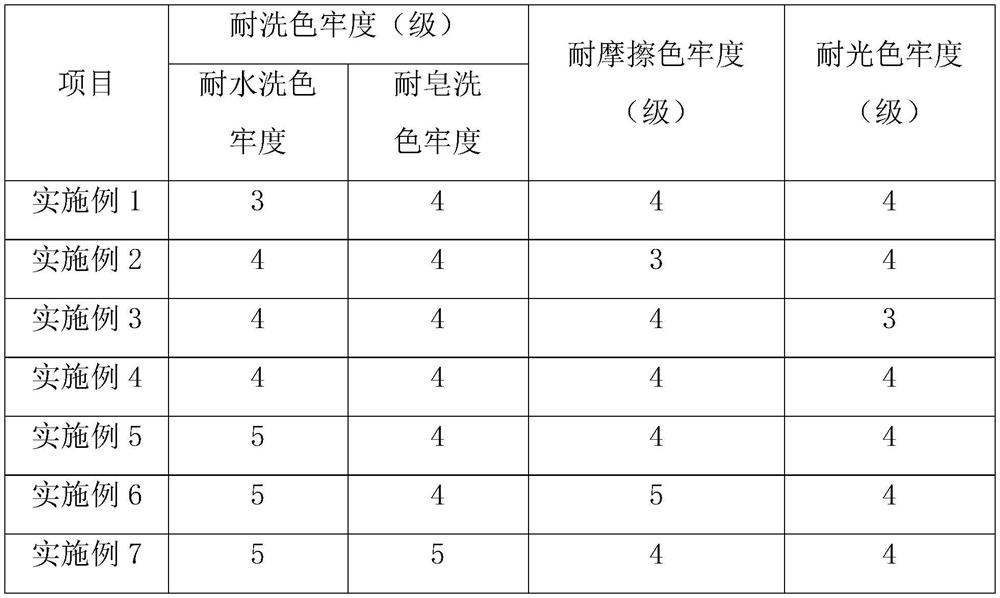

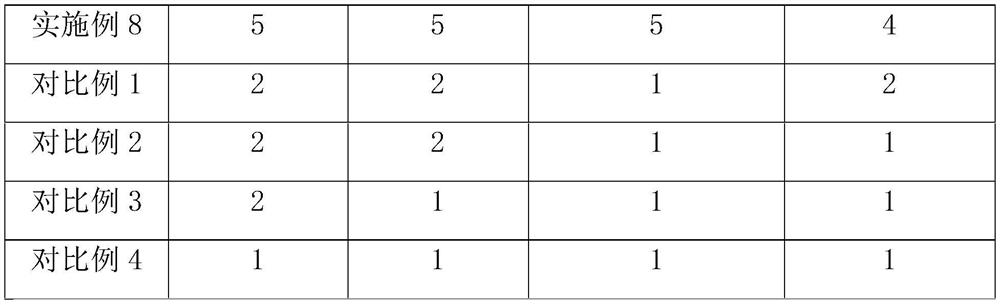

Examples

Embodiment 1

[0064] Adopt the following water-saving spray dyeing process according to the application to produce high color fastness yarn:

[0065] Yarn pretreatment: heat the polyester yarn in 0.2g / L sodium hypochlorite aqueous solution at a temperature of 90°C for 20 minutes with a bath ratio of 4, then wash it with cold water and drain the water with a bath ratio of 3 at a temperature of 90°C Set aside to dry.

[0066] Process A, spray-dyeing yarn: under the conditions of temperature of 70°C and pressure of 0.3MPa, the dyeing liquid is spray-dyeing polyester yarn at a flow rate of 40L / min, and one spray-dyeing acts on 12 yarns at the same time. Dry naturally after finishing;

[0067] Step B, steaming the yarn after spray dyeing: steaming the yarn treated in the step A at a temperature of 180° C. for 8 minutes and then cooling to obtain the steamed yarn;

[0068] Process C, washing the yarn after spray dyeing: soak the yarn obtained in the process B in water at 0°C for 3 minutes at a ...

Embodiment 2

[0075] Adopt the following water-saving spray dyeing process according to the application to produce high color fastness yarn:

[0076] Yarn pretreatment: heat the polyester yarn in 0.5g / L sodium hypochlorite aqueous solution at a temperature of 80°C for 30min with a bath ratio of 2, then wash it with cold water and drain the water with a bath ratio of 5 at a temperature of 85°C Set aside to dry.

[0077] Process A, spray-dyeing yarn: under the condition of temperature of 65°C and pressure of 0.6MPa, the dyeing liquid is spray-dyeing polyester yarn at a flow rate of 20L / min, and one spray-dyeing acts on 24 yarns at the same time. Dry naturally after finishing;

[0078] Step B, steaming the yarn after spray dyeing: steaming the yarn treated in the step A at a temperature of 170° C. for 10 minutes and then cooling to obtain the steamed yarn;

[0079] Process C, washing the yarn after spray dyeing: first soak the yarn obtained in the process B in -5°C water for 5 minutes, with ...

Embodiment 3

[0086] Adopt the following water-saving spray dyeing process according to the application to produce high color fastness yarn:

[0087] Yarn pretreatment: heat the polyester yarn in 0.2g / L sodium hypochlorite aqueous solution at a temperature of 80°C for 20min at a bath ratio of 2, then wash with cold water and drain the water at a temperature of 85°C Set aside to dry.

[0088] Process A, spray-dyeing yarn: under the condition of temperature of 65°C and pressure of 0.3 MPa, the dye solution in process B is spray-dyeing polyester yarn at a flow rate of 20 L / min, and one spray-dyeing effect is applied to 12 polyester yarns at the same time. On the yarn, dry it naturally after spraying and dyeing;

[0089] Step B, steaming the yarn after spray dyeing: steaming the yarn treated in the step A at a temperature of 170° C. for 8 minutes and then cooling to obtain the steamed yarn;

[0090] Process C, washing the yarn after spray dyeing: first soak the yarn obtained in the process B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com