Geological detection system for horizontal drilling machine

A technology of geological exploration and horizontal drilling rigs, which is applied in the directions of surveying, earthwork drilling, and undisturbed core extraction devices. The effect of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

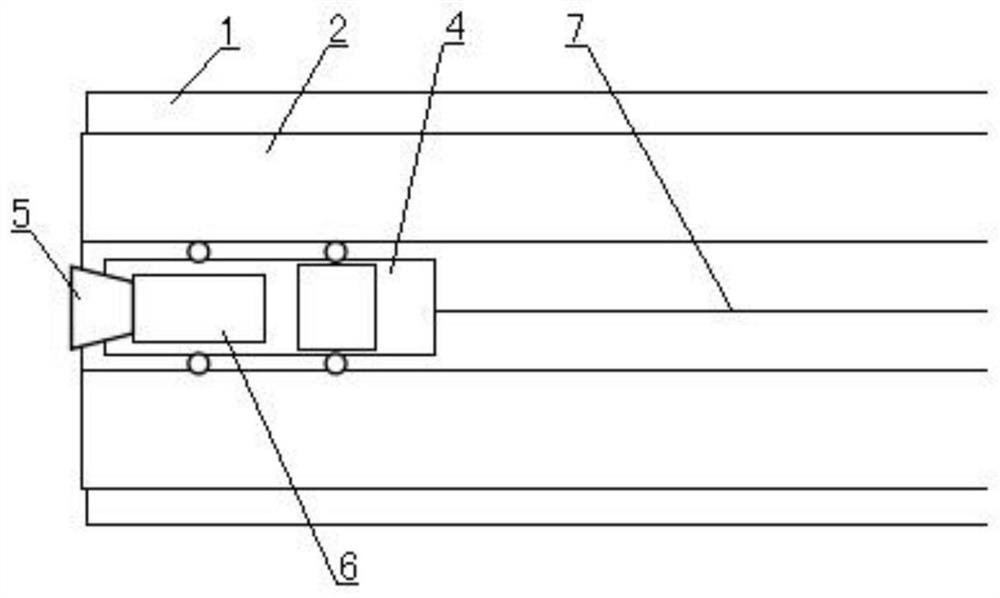

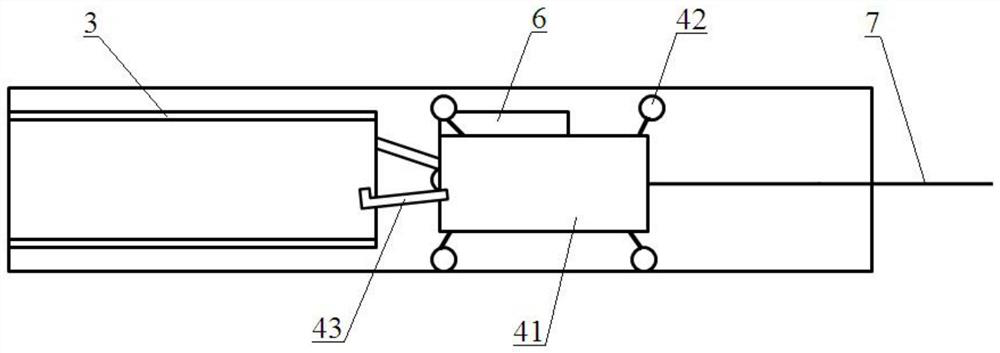

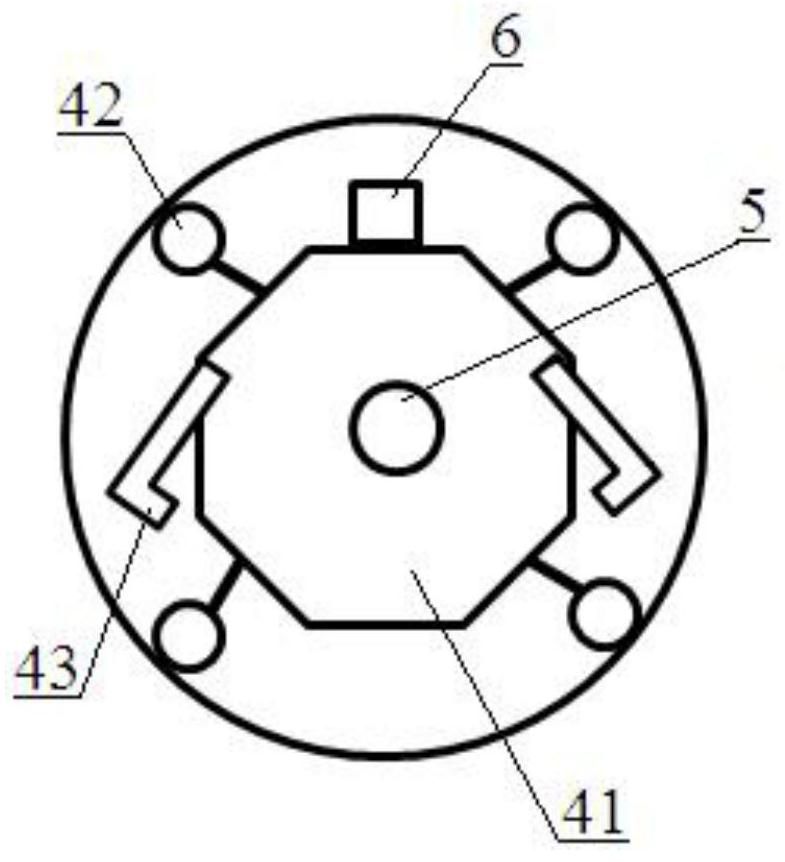

[0030] see Figure 1-Figure 4 , a geological detection system for a horizontal drilling rig, including a horizontal coring system and a robot detection system. The horizontal coring system includes an outer casing 1 , a down-the-hole hammer 2 and a core remover 3 , and the robot detection system includes a pipeline robot 4 , a camera system 5 , detection equipment 6 and a wire rope 7 .

[0031] The down-the-hole hammer 2 and the drill pipe are coaxially arranged front and rear, and both are arranged in the outer casing 1. The down-the-hole hammer 2 cooperates with the drill pipe to break rocks by advancing, impacting and rotating, and at the same time adopts high pressure to carry slag The method is positive circulation slag removal, a connected coring channel is provided in the down-the-hole hammer 2 and the drill pipe, and the coring device 3 is arranged in the coring channel and used to realize rock formation coring. By controlling the pipeline robot 4 to enter the central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com