Newton internal friction law rotation damper

A technology of rotary damper and internal friction, applied in the direction of mitigating undesired effects, etc., can solve problems such as lack of data and design parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

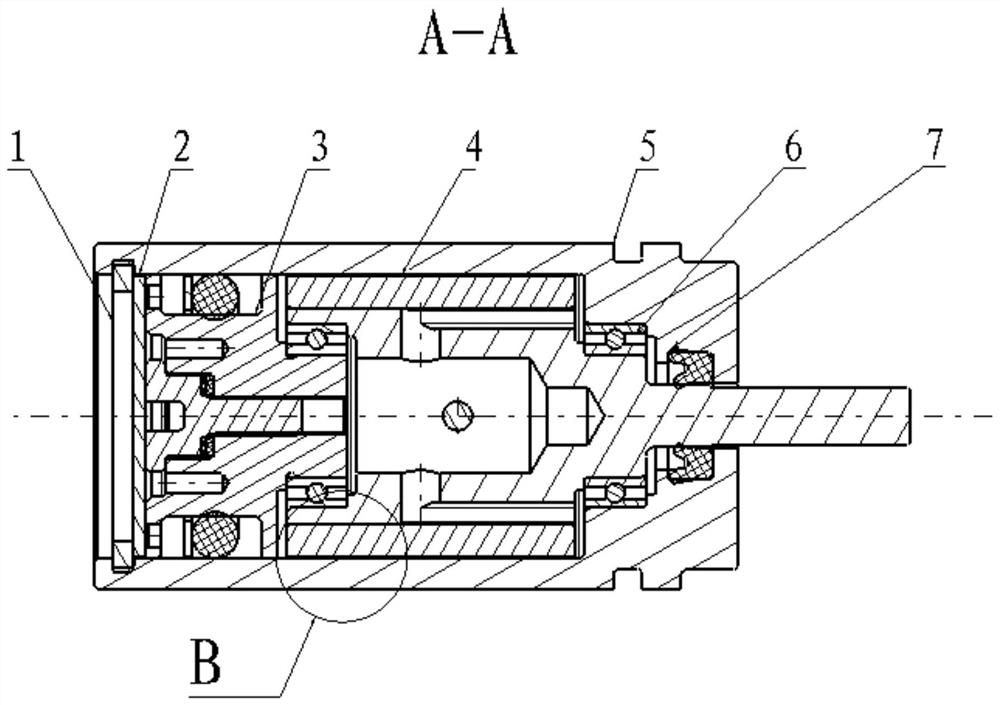

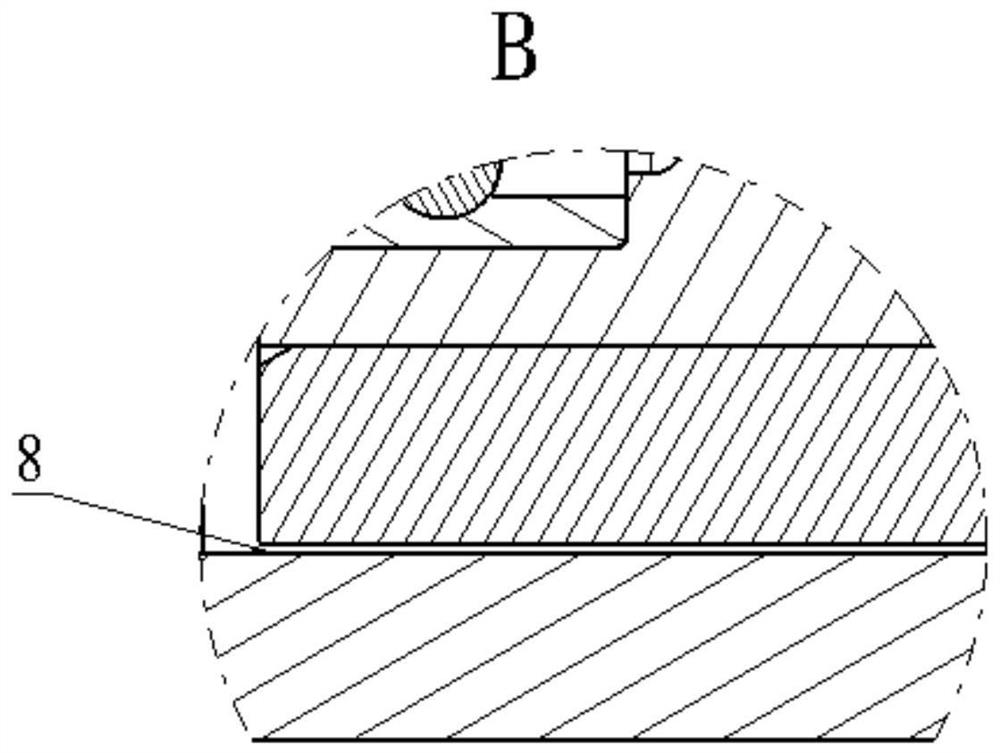

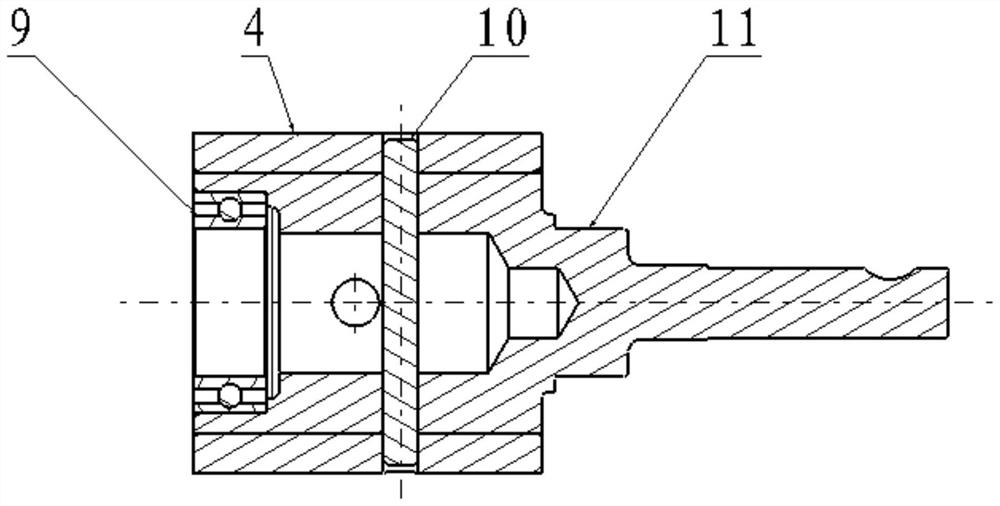

[0021] refer to Figure 1-Figure 5 , in the preferred embodiment described below, a rotary damper with Newton's law of internal friction, including: a rotary piston 4 with temperature compensation function installed in the damping cavity of the damping cylinder 5, through which the hollow cavity of the rotary piston 4 extends out of the damping The piston rod 11 of the cylinder 5, and the materials with different thermal expansion coefficients are selected for the rotary piston 4 and the damping cylinder 5. The thermal expansion coefficient of the material of the rotary piston 4 is greater than that of the damping cylinder 5. Among them: an end cover assembly 3 with oil volume compensation passes through the front end The stepped shaft cylinder seal is assembled in the step hole at the tail end of the piston rod 11, and forms a variable volume sealing cavity filled with damping working medium with the damping cylinder 5 and the rotary piston 4. The outer circle of the rotary pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com