Over-temperature protection circuit for low-power-consumption chip

An over-temperature protection circuit, low-power technology, applied in the direction of adjusting electrical variables, control/regulating systems, instruments, etc., can solve the problems of reducing the layout area, increasing the layout area, and excessively large layout area, and achieving low power consumption Over-temperature protection and hysteresis, less circuit branches, and low overall consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

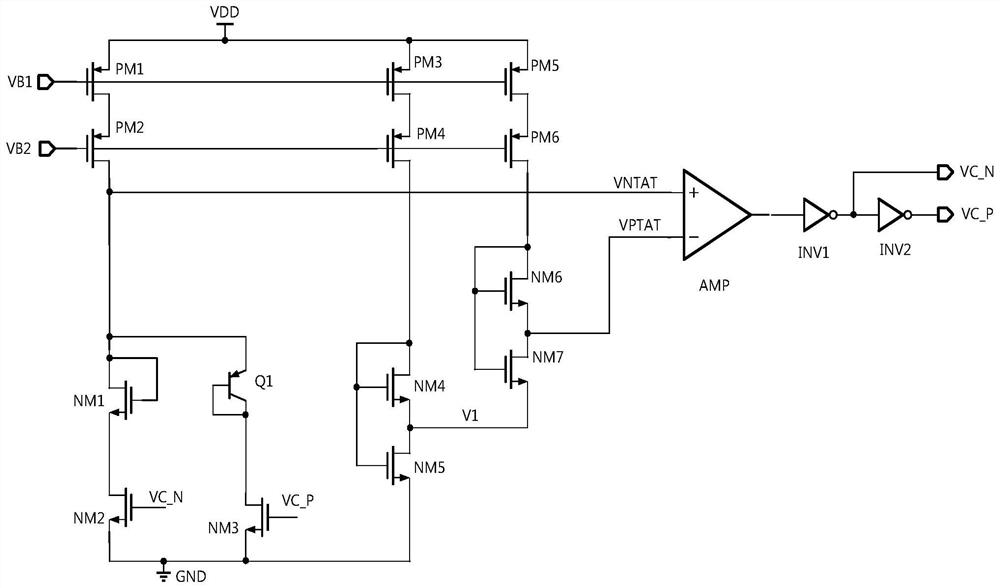

[0042] Over-temperature protection circuit for low-power chips, such as Figure 2-Figure 3 As shown, it includes: first current mirror, second current mirror, third current mirror, NMOS transistor NM1, NMOS transistor NM2, triode Q1, NMOS transistor NM3, operational amplifier AMP, NMOS transistor NM4, NMOS transistor NM5, NMOS transistor NM6 , NMOS transistor NM7, inverter INV1 and inverter INV2, the NMOS transistor NM1 is connected in series with the NMOS transistor NM2, the triode Q1 is connected in series with the NMOS transistor NM3, the NMOS transistor NM1 and the NMOS transistor NM2 are connected in parallel with the triode Q1 and the NMOS transistor NM3 It is connected in series with the first current mirror, the NMOS transistor NM4 is connected in series with the NMOS transistor NM5 and then connected in series with the second current mirror, the NMOS transistor NM6 is connected in series with the NMOS transistor NM7 and then connected in series with the third current m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com