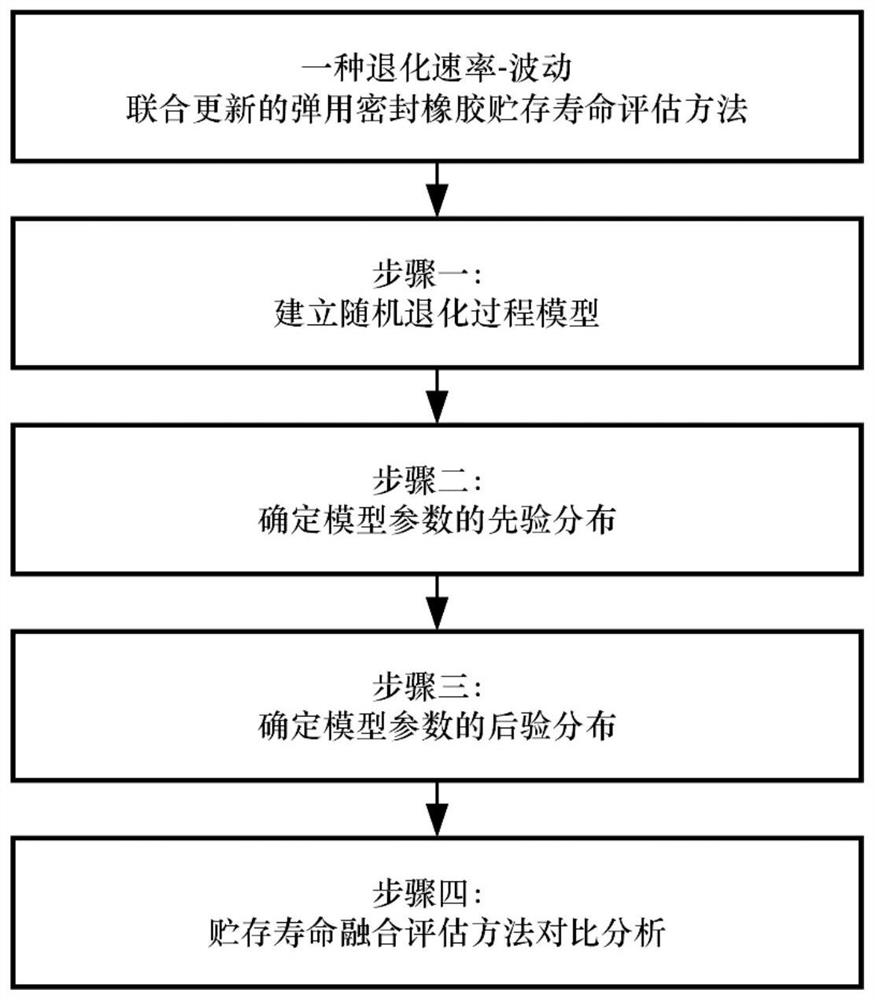

Degradation rate-fluctuation combined updated storage life evaluation method for sealing rubber for missile

A technology for storage life and sealing rubber, which is applied in the direction of probability network, probability CAD, design optimization/simulation, etc., can solve the problem of inaccurate evaluation of storage life, and achieve scientific evaluation methods, strong operability, and wide application value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0117] The present invention will be explained in detail below in combination with actual cases.

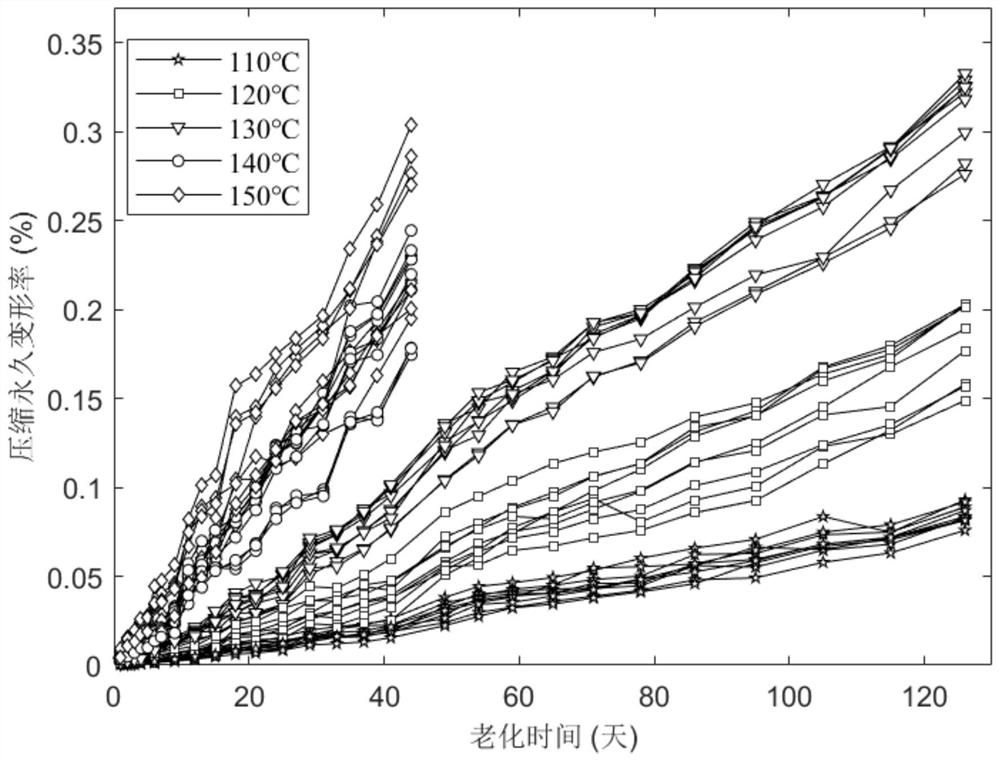

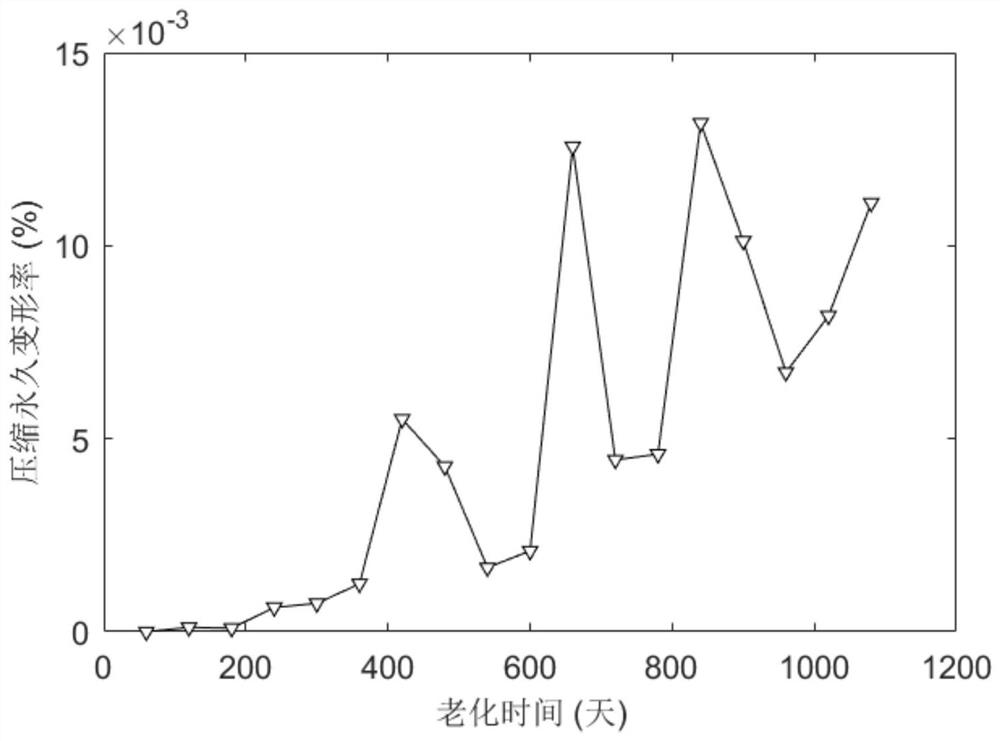

[0118] As a typical sealing material, silicone rubber has been widely used in mechanical systems, and its performance directly affects the reliability and safety of the system. At high temperature, heat aging is a key failure mode of 3S-60 silicone rubber, and its degradation is characterized by compression set rate. In order to study the thermal aging process of 3S-60 silicone rubber, an accelerated aging test was carried out on it, and its compression set rate was measured. There are 45 samples in this data set, which are divided into 5 groups, and 9 samples in each group are tested at different temperature levels, and the compression set of rubber is measured. Determine the temperature levels of the laboratory accelerated heat aging test for 3S-60 silicone rubber as 150°C, 140°C, 130°C, 120°C and 110°C. The working temperature level of 3S-60 silicone rubber under normal stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com