Powder marinating material and preparation method thereof, and processing method of marinated meat products

A processing method and marinade technology, applied in climate change adaptation, food science, etc., can solve the problems of discarding, inefficient use, dissolution, diffusion and slow penetration of marinade and marinade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

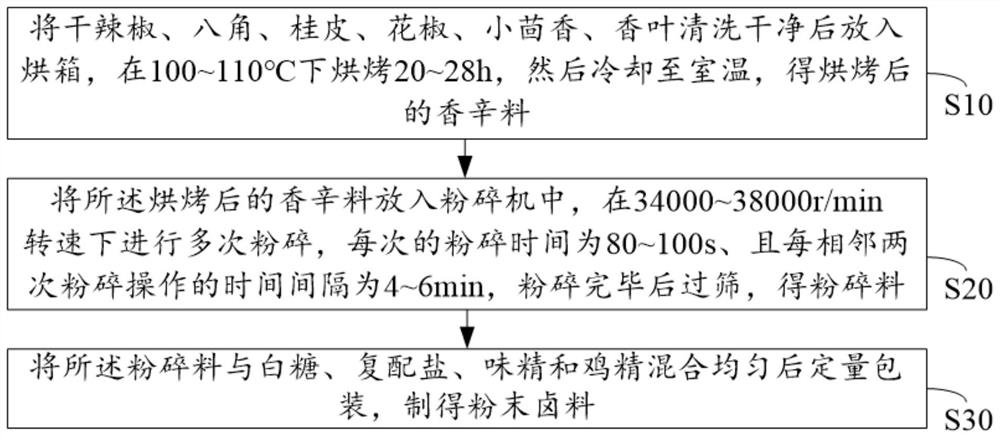

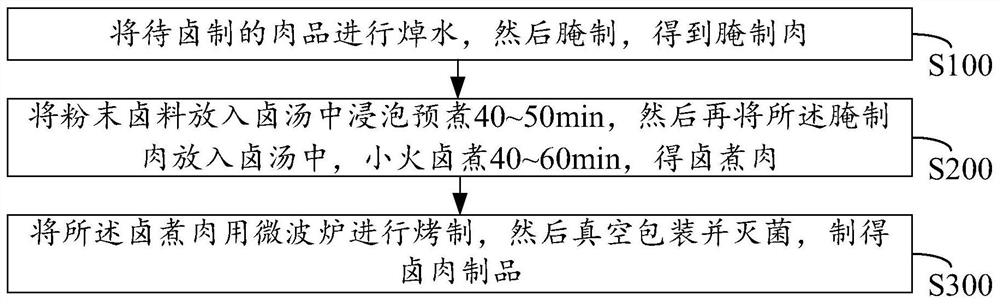

[0043] Further, the present invention also proposes a method for preparing the above-mentioned powdered brine, figure 1 Shown is an embodiment of the preparation method of the powdered brine provided by the present invention. refer to figure 1 Shown, in the present embodiment, the preparation method of described powder halogen material comprises the following steps:

[0044] Step S10, clean the dried chili, star anise, cinnamon, Chinese prickly ash, cumin, and fragrant leaves, put them into an oven, bake at 100-110° C. for 20-28 hours, and then cool to room temperature to obtain baked spices;

[0045] Step S20, put the roasted spices into a pulverizer, and perform multiple pulverization at a speed of 34,000-38,000 r / min, each pulverization time is 80-100 s, and the time for every two adjacent pulverization operations is The interval is 4 to 6 minutes. After the crushing is completed, sieve to obtain the crushed material;

[0046] Step S30, uniformly mix the pulverized mater...

Embodiment 1

[0057] (1) Clean the dried chili, star anise, cinnamon, Chinese prickly ash, cumin, and fragrant leaves, put them in an oven, bake them at 110°C for 24 hours, and then cool them down to room temperature;

[0058] (2) Put the spices baked and cooled in step (1) into a pulverizer for high-speed pulverization, the speed of the pulverizer is set at 36000r / min, and each spice is pulverized for 3 times, each time for 90s, and each time The time interval between two adjacent crushing operations is 5 minutes, and after the crushing is completed, pass through a 60-mesh sieve to obtain crushed spices;

[0059] (3) According to 18% dried chili, 5% star anise, 5% cinnamon, 3% fennel, 12% pepper, 15% white sugar, 3% bay leaves, 29% compound salt (potassium chloride and sodium chloride in the The mass fractions in the above-mentioned compound salt are respectively 20% and 80%), monosodium glutamate 5% and chicken essence 5% mass ratio, quantitatively weigh each raw material respectively, th...

Embodiment 2

[0061] (1) Clean the dried chili, star anise, cinnamon bark, Chinese prickly ash, cumin, and fragrant leaves, put them in an oven, bake them at 100°C for 28 hours, and then cool them down to room temperature;

[0062] (2) Put the spices baked and cooled in step (1) into a pulverizer for high-speed pulverization, the speed of the pulverizer is set at 34000r / min, and each spice is pulverized for 3 times, each time for 100s, and every time The time interval between two adjacent crushing operations is 4 minutes, and after the crushing is completed, pass through an 80-mesh sieve to obtain crushed spices;

[0063] (3) According to 19% dried chili, 4% star anise, 5% cinnamon, 2% cumin, 12% pepper, 15% white sugar, 2% bay leaf, 30% compound salt (potassium chloride and sodium chloride in the The mass fractions in the above-mentioned compound salt are respectively 25% and 75%), monosodium glutamate 6% and chicken essence 5% mass ratio, quantitatively weigh each raw material respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com